Tips of the Week is our weekly peek at some of the best making tips, tricks, and recommendations we’ve discovered in our travels. Check in every Friday to see what we’ve discovered. And we want to hear from you. Please share your tips, shortcuts, best practices, and tall shop tales in the comments below and we might use your tip in a future column.

Be Prepared

On a recent Graz Makes, where he fashions a knife out of 1084 steel and a melted down Mac (seriously), John makes an excellent point that should be highlighted. In setting up for putting his knife together, he made sure he had everything he needed, and everything he might need. As he puts it: “Remember, it’s better to have it and not need it than to need it and not have it.” Spoken like a true nerd Scout.

On a recent Graz Makes, where he fashions a knife out of 1084 steel and a melted down Mac (seriously), John makes an excellent point that should be highlighted. In setting up for putting his knife together, he made sure he had everything he needed, and everything he might need. As he puts it: “Remember, it’s better to have it and not need it than to need it and not have it.” Spoken like a true nerd Scout.

Voronoi Patterns for 3D Designs

In a recent post I did on RobotGrrl’s Robot Mission, one of the Make: readers, Ben Hall, observed in the comments: “I like the use of the Voronoi pattern to reduce infill and to strengthen the parts. Plus, it looks super alien-like. Nice touch.” It may sound like a shadowy race on Babylon 5, but the Voronoi pattern is a type of mathematical calculation that creates a cell-patterned structure based on the distance between two points within the cells. In a 3D object, the result is a Swiss-cheesy structure that is very strong while using a minimal amount of material. This results in a surface that is lightweight, uses far less filament (time, and energy), but is still as strong as a solid plane. There’s even an online Voronoi converter, called the Voronator, that will easily convert your 3D design files for printing objects made with Voronoi patterns. Isn’t the internet nifty (when it’s not conspiring to kill us)?

In a recent post I did on RobotGrrl’s Robot Mission, one of the Make: readers, Ben Hall, observed in the comments: “I like the use of the Voronoi pattern to reduce infill and to strengthen the parts. Plus, it looks super alien-like. Nice touch.” It may sound like a shadowy race on Babylon 5, but the Voronoi pattern is a type of mathematical calculation that creates a cell-patterned structure based on the distance between two points within the cells. In a 3D object, the result is a Swiss-cheesy structure that is very strong while using a minimal amount of material. This results in a surface that is lightweight, uses far less filament (time, and energy), but is still as strong as a solid plane. There’s even an online Voronoi converter, called the Voronator, that will easily convert your 3D design files for printing objects made with Voronoi patterns. Isn’t the internet nifty (when it’s not conspiring to kill us)?

Leaving the Shop Lid-Check

This might be one from the Painfully Obvious Department, but I just started to force myself to do this at the end of each one of my model building sessions and I have already found open tops. The idea is that, if you are working with any glues, resins, paints, solvents; any liquid or gel that should not be exposed to the air, before you leave the workbench, you consciously do a final lid-check and carefully check the lids of every liquid you have used. Before doing this, I have ruined expensive hobby paints, glues, and other liquids. Leaving? Lid check.

Using Cloth on Tool Jaws

Another tip from Captain Obvious (that I myself need to be reminded of). Many of us who working in hobby electronics and miniature modeling have already likely applied heat-shrink to alligator clips and needlenose pliers to prevent marring the surfaces of the components we are handling. Eric from Hand Tool Rescue reminds us that you can temporarily wrap a rag around the object you are grabbing, or around the jaws of the grabber, to be able to grip the object with authority without fear of damaging it.

Minwax as a Paint Mask

Here’s another great tip from the Hand Tools Rescue video where Eric restores an antique nail gun. In prepping the restored gun for painting, he placed some Minwax on the screw heads he didn’t want to paint. I have never seen this. Great idea!

Here’s another great tip from the Hand Tools Rescue video where Eric restores an antique nail gun. In prepping the restored gun for painting, he placed some Minwax on the screw heads he didn’t want to paint. I have never seen this. Great idea!

Making Knobs with Bondo

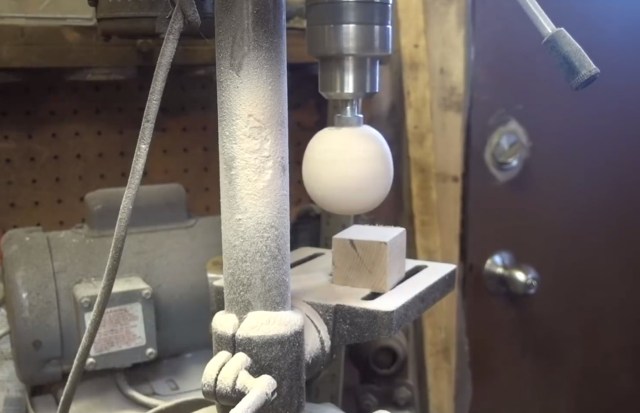

It’s Hand Tool Rescue week here on Tips of the Week. While restoring a very sad-looking 1930s jigsaw, Eric was faced with the dilemma of a missing ball knob. Bondo car body filler to the rescue! He simply created some mounds of Bondo on his workbench, added a bolt before the Bondo set, chucked the rough ball into his drill press, and then hand-sanded it until he had a nice, smooth knob. The resulting knobs look as good as the originals.

It’s Hand Tool Rescue week here on Tips of the Week. While restoring a very sad-looking 1930s jigsaw, Eric was faced with the dilemma of a missing ball knob. Bondo car body filler to the rescue! He simply created some mounds of Bondo on his workbench, added a bolt before the Bondo set, chucked the rough ball into his drill press, and then hand-sanded it until he had a nice, smooth knob. The resulting knobs look as good as the originals.

It’s a Book!

Earlier this week, we finally shipped off my ninth book, Tips and Tales from the Workshop to the printer. It should be out by the first of June. It is available now for pre-order on Amazon. Those who have seen early proofs of it are very excited. Kevin Kelly of Cool Tools declares: “Gareth Branwyn is the Tip Master. He scours the workshops of the world for practical, time-saving, life-altering tips to help you make stuff better, faster, cheaper.” Becky Stern, of Instructables, says: “It’s ah-ha moment overload!” And John Park of Adafruit is steamed at me: “Tips and Tales is so darned good, I’m kind of mad that Gareth didn’t write it decades ago.” A lot of this book collects the best of this column, so it really feels like it was ultimately a community effort. Thanks to all of the amazing makers who do that voodoo that you do. I tried to capture some of that magic within these pages.

Earlier this week, we finally shipped off my ninth book, Tips and Tales from the Workshop to the printer. It should be out by the first of June. It is available now for pre-order on Amazon. Those who have seen early proofs of it are very excited. Kevin Kelly of Cool Tools declares: “Gareth Branwyn is the Tip Master. He scours the workshops of the world for practical, time-saving, life-altering tips to help you make stuff better, faster, cheaper.” Becky Stern, of Instructables, says: “It’s ah-ha moment overload!” And John Park of Adafruit is steamed at me: “Tips and Tales is so darned good, I’m kind of mad that Gareth didn’t write it decades ago.” A lot of this book collects the best of this column, so it really feels like it was ultimately a community effort. Thanks to all of the amazing makers who do that voodoo that you do. I tried to capture some of that magic within these pages.

ADVERTISEMENT

Join Make: Community Today