My tools: a pool cue, pliers, and some T-pins. My goal: a one-of-a-kind engagement ring.

bout three years ago I made a life changing decision. I decided I wanted to spend the rest of my life with my girlfriend, Becky. In order to pop the big question, I obviously needed a ring to propose with. I had no idea where to start looking for a ring. I tied knots as a hobby so my sister pointed me to a site where they sold hand made woven rings called Turk’s head knots. I loved the idea, but I also wanted a ring with a diamond. It occurred to me that I could just make one myself! I didn’t know if I was biting off more than I could chew, so I experimented before committing to the idea.

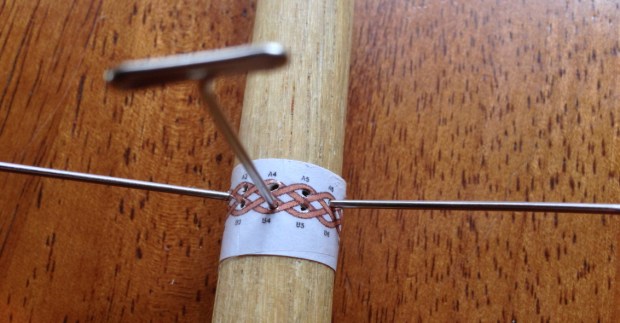

I picked up some beading wire and gave it a shot. My first ring was tied around rolled up cardboard with a paper print out of the knot so I could follow it. I stole some T-pins from the office supply room at work and used them to weave the ring. By the end, the cardboard was all torn up and bits of it were stuck in between the wires, but I had a ring! My first attempt was very uneven, but considering what I was using it showed promise. I used the cardboard and T-pins technique a couple more times before I created a ring that convinced me that I could make a ring good enough to be an engagement ring (it was this same ring that was actually blessed at the wedding ceremony).

My first attempt:

The ring that convinced me I could make a real engagement ring and that was blessed in the wedding ceremony:

If I was really going to make an engagement ring, I needed to have a way to repeatedly make the same ring. That meant I’d need something sturdier than the cardboard. I went to a local billiards store to buy the cheapest pool cue they had. I explained what I was doing and the owner went in the back and came back with a very short pool cue form. He didn’t even charge me for it. Then I ordered some tiny Dremel bits that could drill holes for the T-pins that I had. Because the pool cue tapered, I could drill the holes wherever I needed to once I got to sizing the ring.

Pool cue with a paper print out of a knot taped around it with T-pins:

For months I experimented with different wire thicknesses, different weaves, twisted wire vs regular wire, as well as how I would incorporate a gem setting. Here are some examples. The last one is the closest to what her ring is.

My sister’s diamond earring stuck into a band with twisted wire:

Miscellaneous practice rings, one with a basket woven in for a gem:

This is very close to the final ring that I made for my wife (I made some minor adjustments to the basket, before making the switch to gold wire):

At this point, I started talking to a jeweler about how I could set a gem into the woven ring that I had tied. Given the small gauge wire that I wanted to use, I knew that there would have to be a reinforcing band. The jeweler designed a band with a channel in it for the woven piece to fit in which was also thick enough to attach a gem setting to. With the design set, I made the switch to gold wire and handed it off to the jeweler. I also handed over a diamond from my Grandma’s necklace to set into the ring. I proposed on the Friday of 4th of July weekend at her parents’ lake house before friends and family came for a great weekend of wake boarding, hammock napping, and rope swing fun.

The final ring before handing it over to the jeweler:

Another shot of the final ring before the jeweler got a hold of it:

My grandma’s diamond necklace. I used the bottom diamond in my wife’s engagement ring.

The final ring:

The whole process led to my current business endeavor called Freakin’ Sweet Knots. Every time I tied a ring, it was to see what it would look like with a certain weave, wire thickness or size. It took hours to tie the ring and often there’d be something I didn’t like about it. It occurred to me that I could write a program that could handle making these little changes and previewing what the ring would look like in 3D. Once you have a design you like, you can order it and it’ll be 3D printed and shipped to you. Try it out at freakinsweetapps.com. For a more detailed explanation of how I made her ring, you can check out this Instructable.

See all of our Valentine’s Day-related posts here.

2 thoughts on “Tying the (Turk’s Head) Knot — How I Made an Engagement Ring”

Comments are closed.

ADVERTISEMENT

Join Make: Community Today

Reblogged this on A Quiet One.