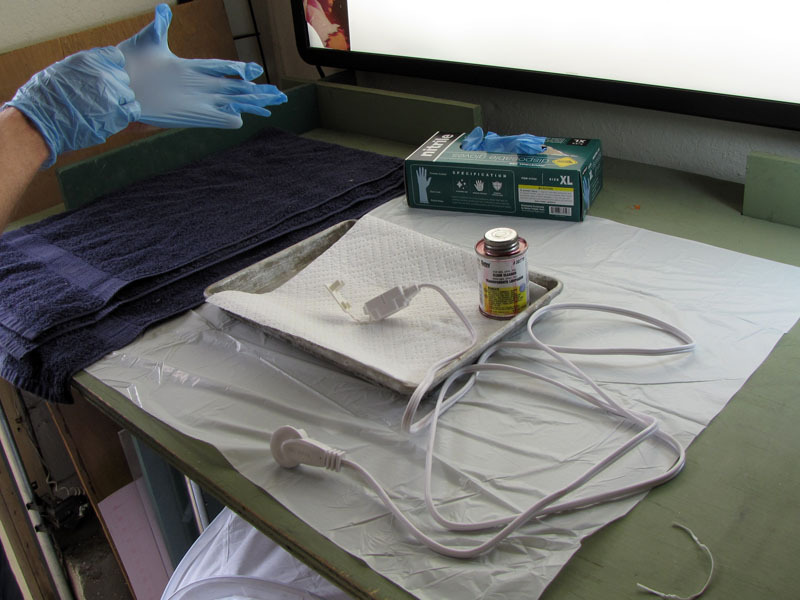

If you want an extension cord, power cord, or other plastic-insulated cable in an unusual color, and you can find one in white, there’s a good chance you can dye it to suit your preference using this technique.

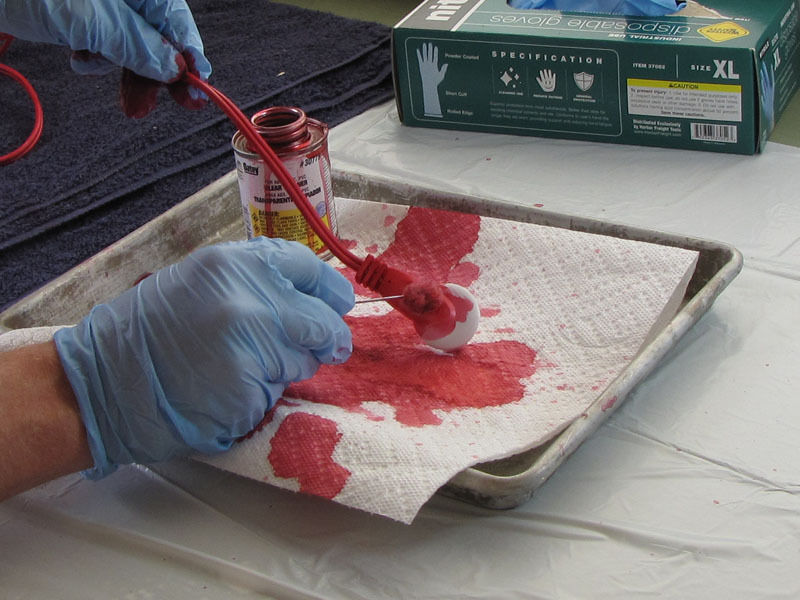

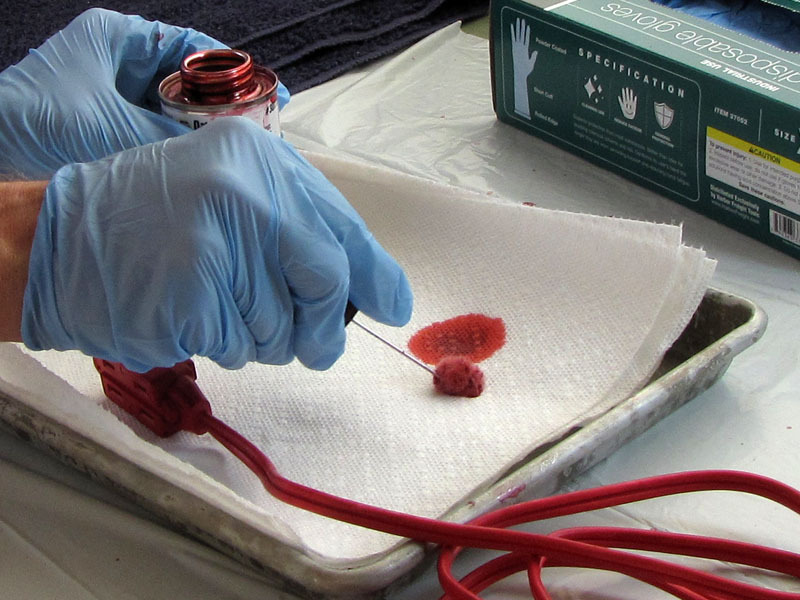

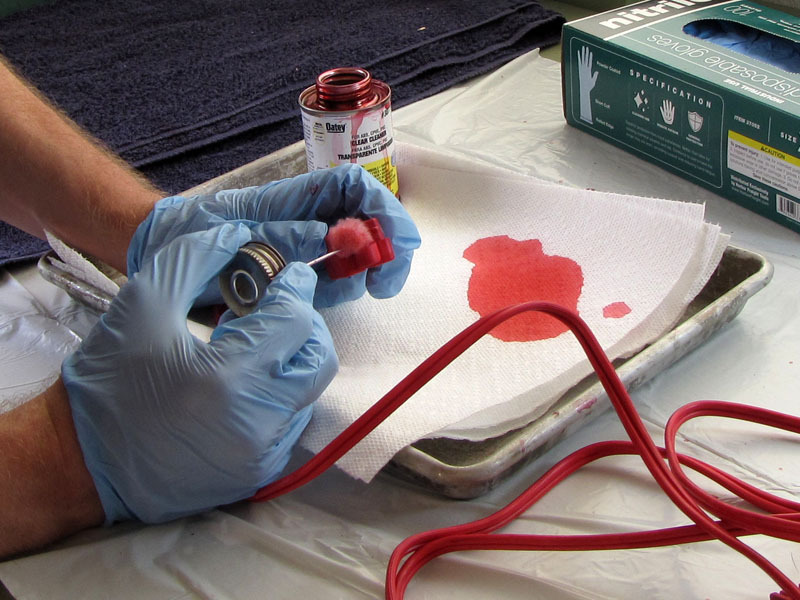

Turns out many cables are sheathed with PVC, and will take the same oil-based stains as PVC pipe. If you want a purple cord, for instance, you can just treat a white PVC cord with purple primer. If you want some other color, it is easy to prepare your own custom stains from clear PVC cleaner and concentrated solvent dyes.