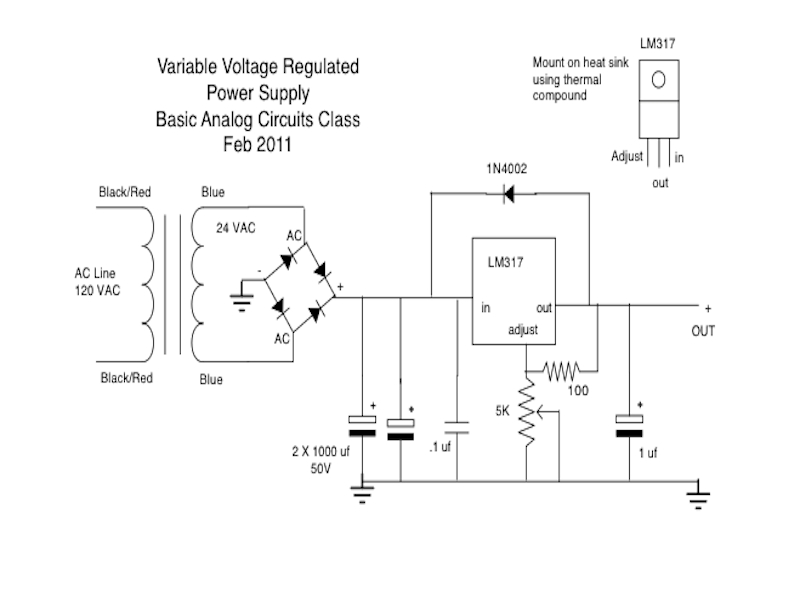

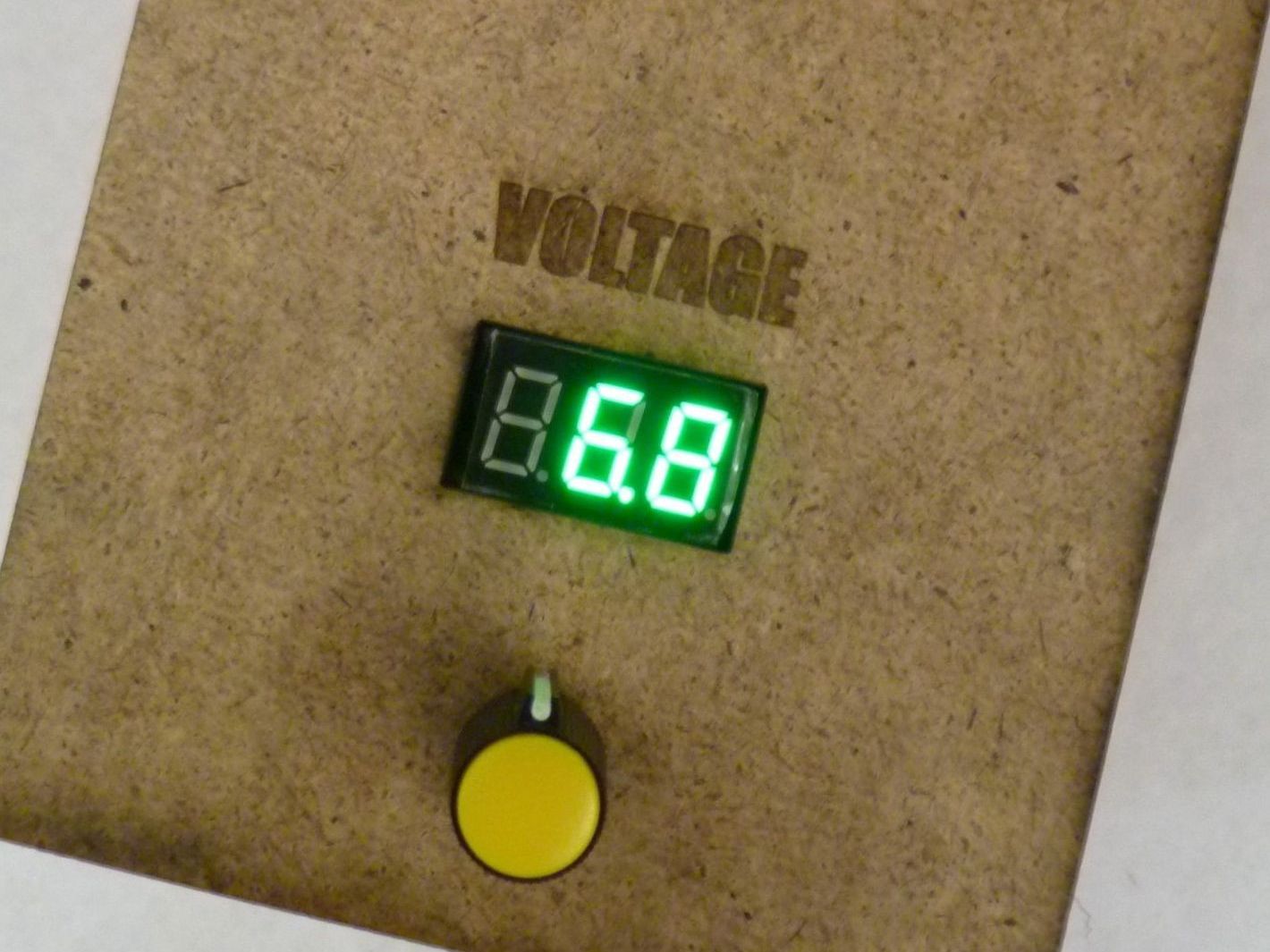

Hobbyist electronics projects need robust, reliable power supplies for prototyping and testing. I learned how to build this circuit from the Basic Analog Circuits class at ITP taught by Eric Rosenthal, but took it several steps further in building a solid enclosure and integrating a voltage meter. Now it lives on my desk, ready to power most small projects I’m working on.

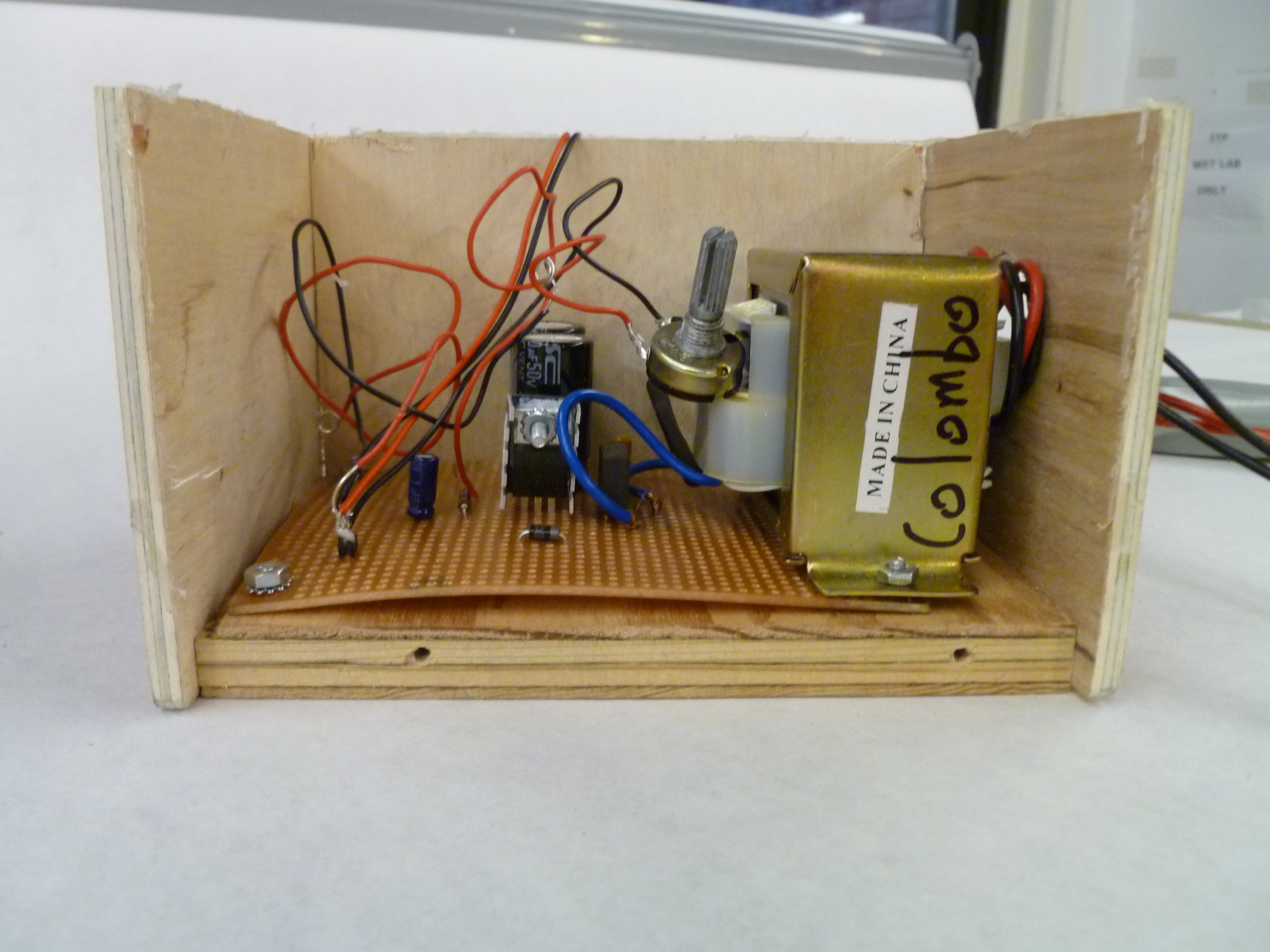

You’ll see example shots of point-to-point wiring of components to perfboard while following a schematic for this power supply. A wood enclosure is built, and Adafruit’s Mini Volt Meter, Vout posts, and a potentiometer are mounted in the final product.

Parts List:

- One 3×5″ perfboard

- LM317 variable voltage regulator

- BR805D Bridge Rectifier

- Heat Sink

- 120 VAC to 24 VDC transformer (mine is part number LP-575)

- Power cable

- Two 1000 microfarad capacitors

- One 0.1 microfarad capacitor

- One 1 microfarad capacitor

- One 100 ohm resistor

- One 5k ohm variable resistor

- One 1N4002 diode

- 1/2″ plywood

- 1/8″ wood or MDF

- six half inch wood screws

- 8 1/2″ long x 1/8″ wide nuts and bolts

- Plastic knob

- Mini volt meter from Adafruit Industries