An ion thruster produces a flow of air even though it has no moving parts. A version of this seemingly impossible device is used on a larger scale to propel deep space probes for NASA. The advantage to this system over others is that you need only an electrical source to power the device and it has no moving parts so it is almost unbreakable. So why aren’t we using this to power our cars, boats, planes, and hovercrafts?

There are a few reasons, but they may not be the ones you think. The first idea you might have is that it’s just too expensive. This is certainly not the case: the device that I show you how to build today cost me less than $10 in new materials (I already had some solder, flux, wood, an NST, and Variac lying around). The second reason you might think of is that the device is just too complex. This would also be an incorrect assumption. As I said above, I am going to show you how to make this device today. It can take as little as 2 hours.

So why don’t we use this technology? Well, the primary reason is that the thrust of the device that I will show you how to construct is, simply put, miniscule. The 12,000 volts of power that the device runs on can only manage to lightly blow a piece of tissue paper. Nevertheless, it does produce a flow of air without any moving parts.

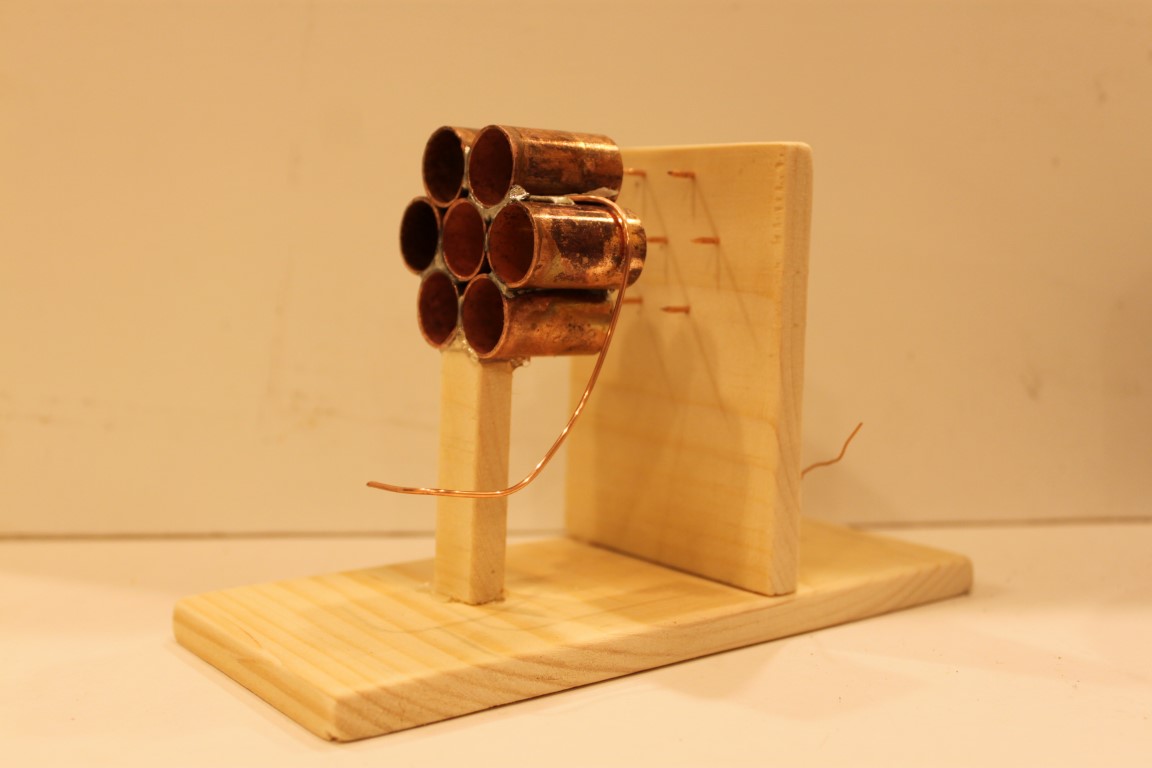

Today I will show you how to build your very own over-engineered and extremely dangerous fan out of little more than some copper pipe fittings, nails, and an NST (if you don’t know that NST stands for neon sign transformer, you should definitely learn more about the dangers of high voltage before you proceed). The device essentially is just two poles of an HV source. The poles are kept far enough away from each other so they ionize the surrounding air but do not arc. The ions produced flow towards the other pole of the voltage. Although the ions are all absorbed, the surrounding air that wasn’t ionized gains enough momentum so that it keeps going in the direction you aim for.

WARNING: The transformer used in this project produces voltages and current that CAN be LETHAL. If you are using a variable autotransformer to power your ion thruster, pushing the transformer beyond 120 volts is a VERY bad idea. Transformers can fail even when they are within their normal range of operating voltage. Only allow your transformer to operate in its normal voltage range. Take great care to safely discharge the transformer before approaching it. Never leave a transformer plugged in when you are not near the power cord.