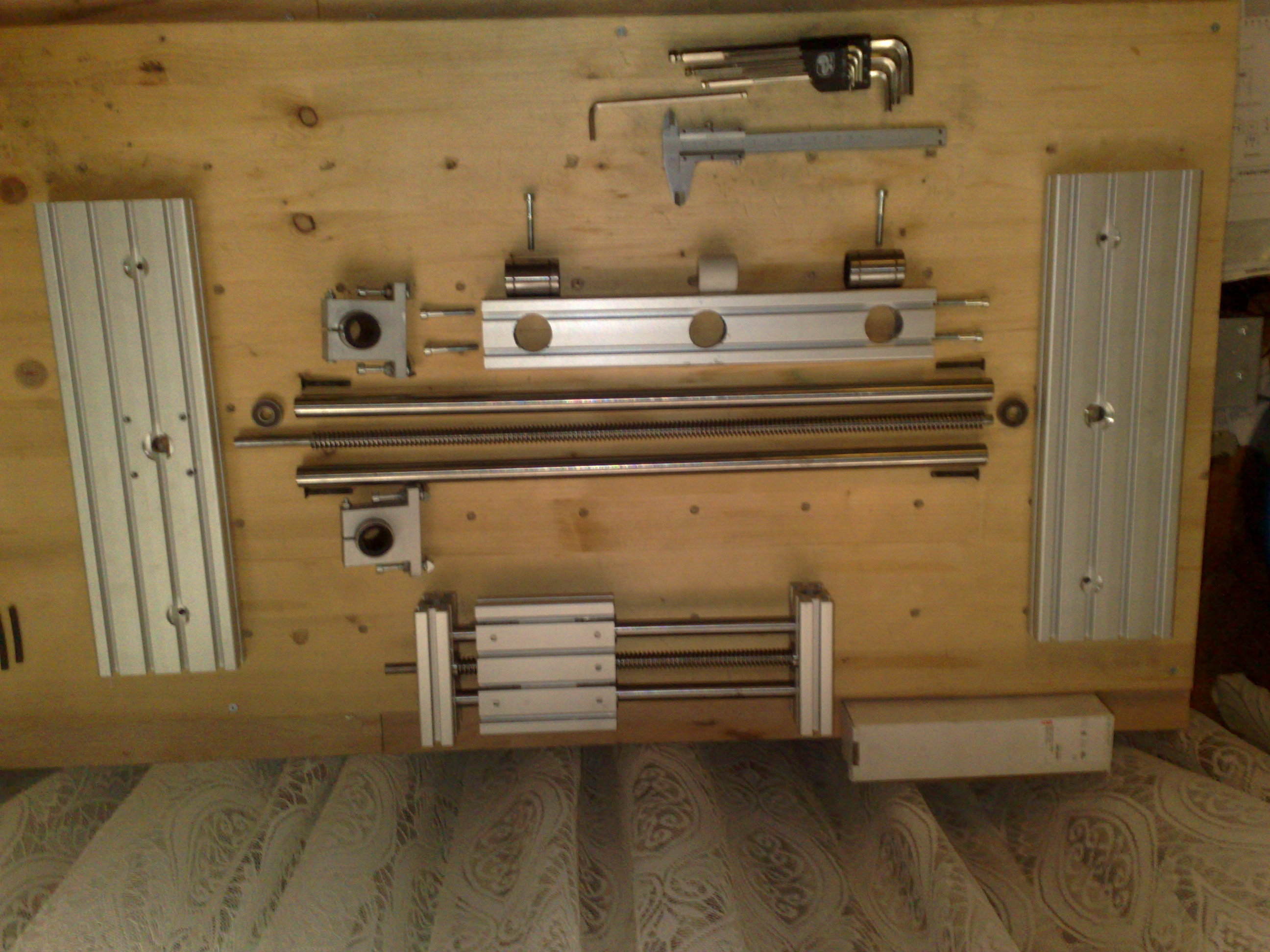

The mini CNC router is simple to build. If you have all the materials and parts prepared you should have it ready to work in less than 5 days.

I needed to build this mini CNC machine so I can make faster and more precise parts that I need for my other home projects.

You can also find the complete instructions at http://www.instructables.com/id/Mini-CNC… until I complete it here.