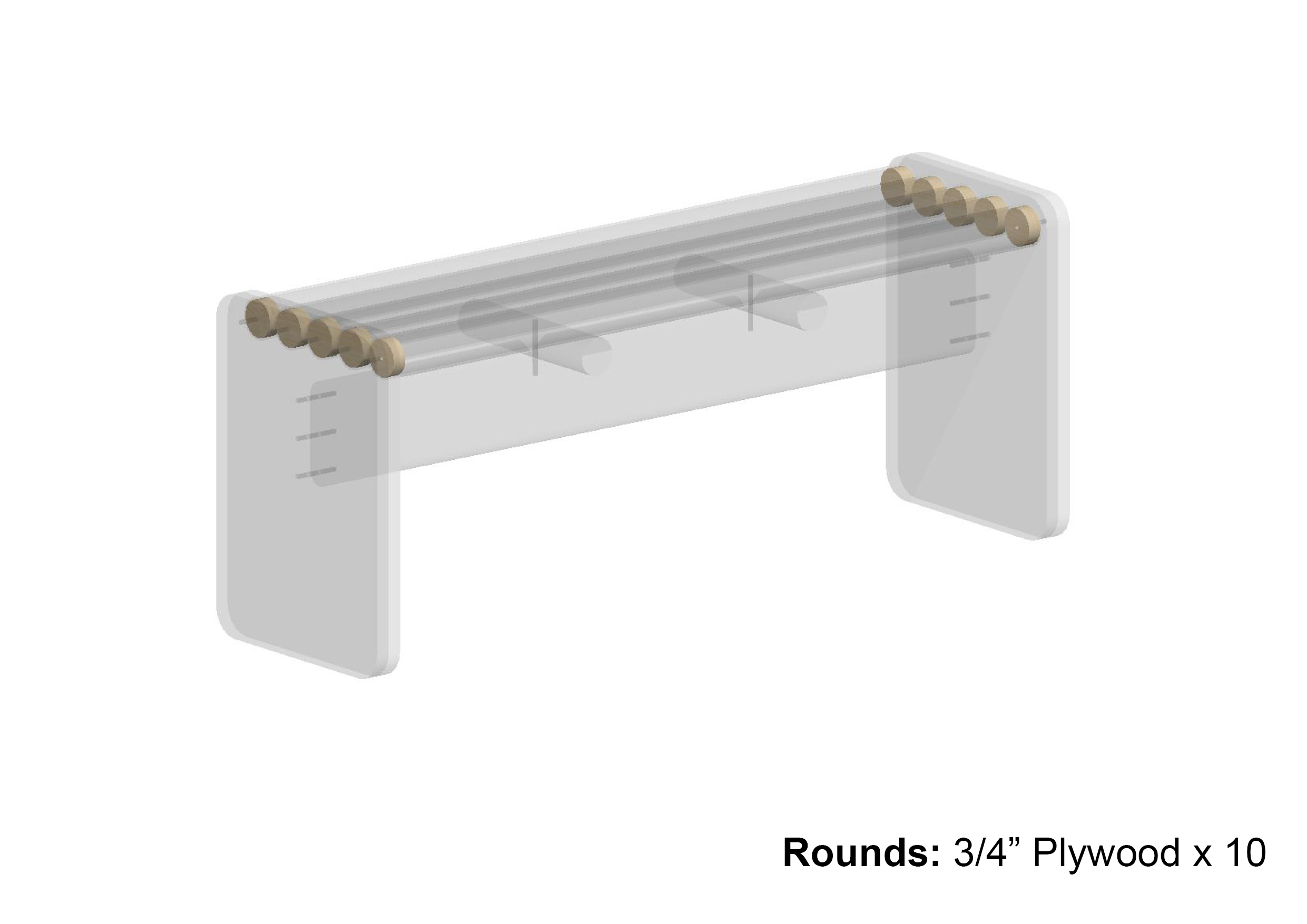

There is a large-format printer at my work that uses 42-inch wide rolls of paper. When the paper’s all used up, the thick cardboard tube at its center is left behind, just begging to be recycled into a project.

I started collecting these paper tubes at the office, not knowing what I would use them for. Normally these are discarded, but I just couldn’t let that happen. We only have four chairs in our dining room so it seemed like a good idea to build a dining room bench from a few of these.

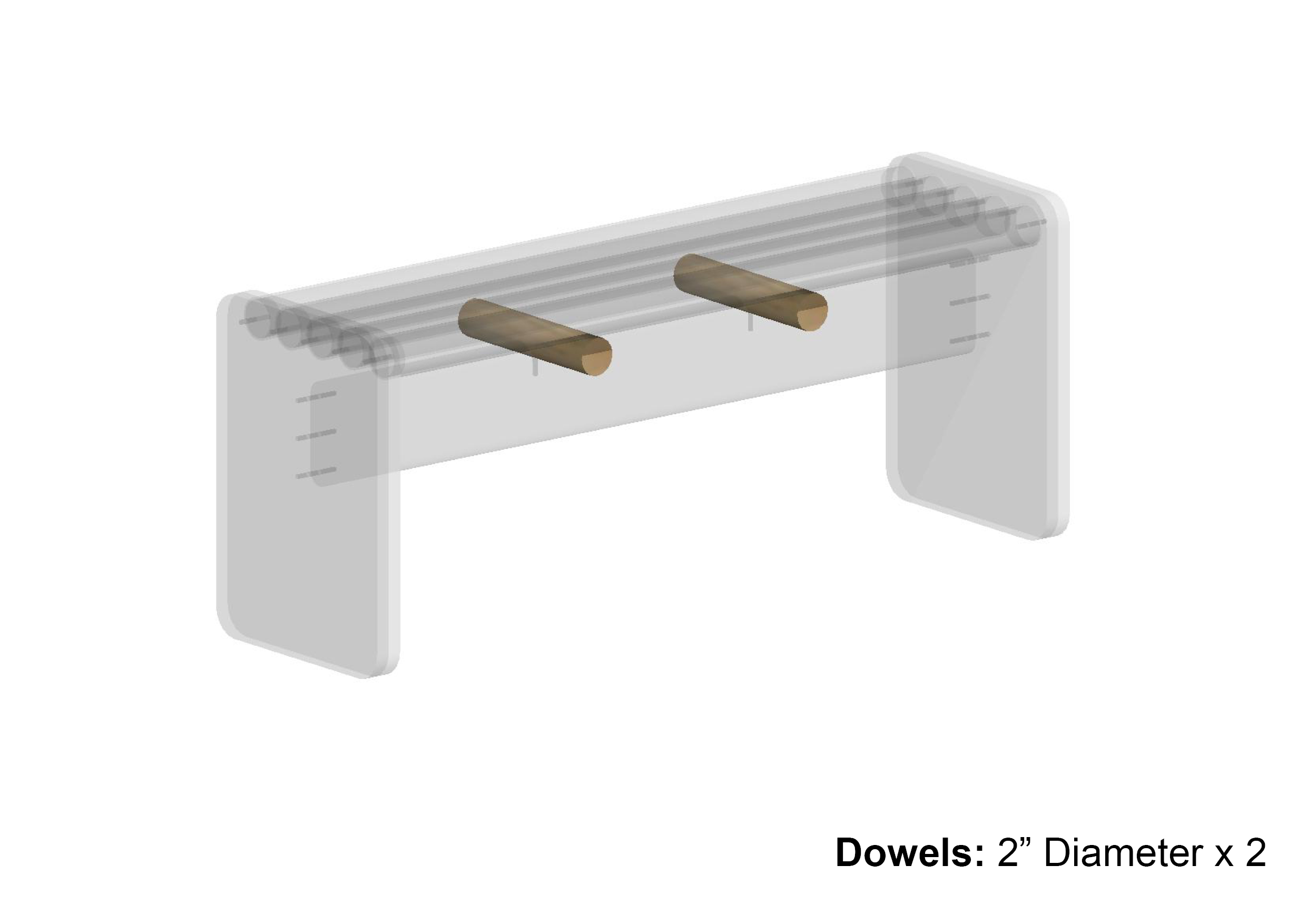

They are exceptionally strong when used vertically but I wanted to use them horizontally for a bench seat. So, I had to make sure that they can carry the weight of 2-3 people at a time. And even though they seem to be strong enough, I added extra support underneath for safety.