By Joan Sheridan Hoover and Becca Olsen

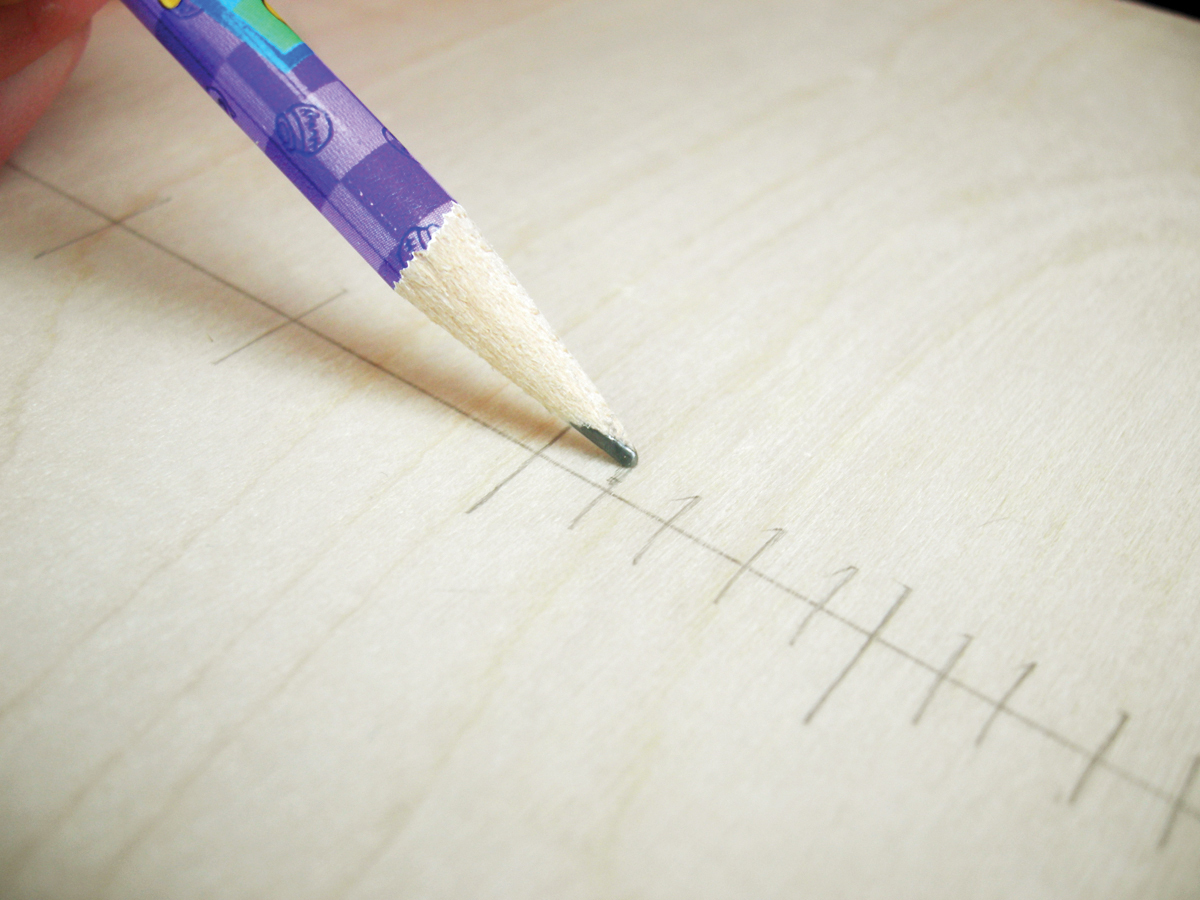

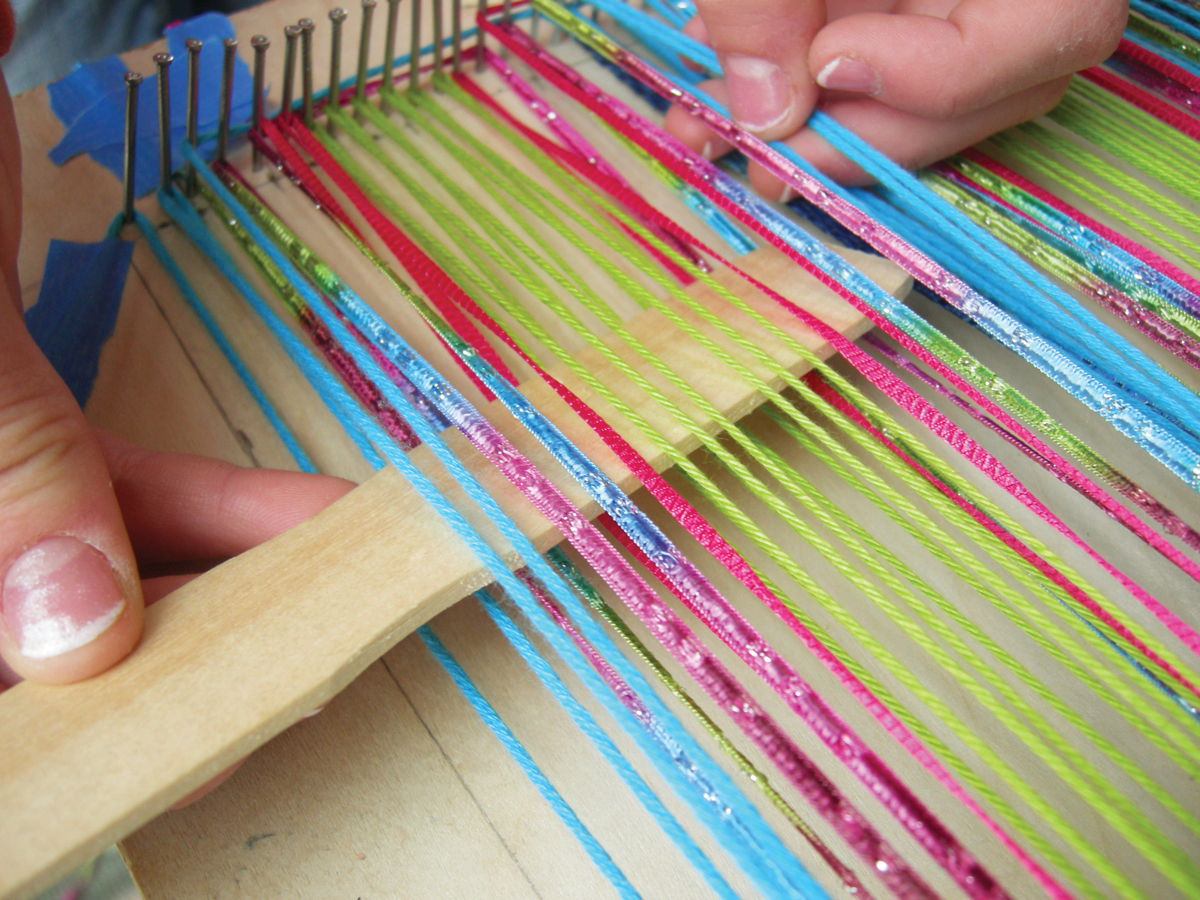

The rhythm of weaving is soothing, and creating your own fabric is addictive. Weaving is easy (remember those potholder looms you used as a kid?) and you can do it with things you probably already have around the house. We raided our knitting stash for yarns and used a scrap of plywood and a box of nails to make the loom.

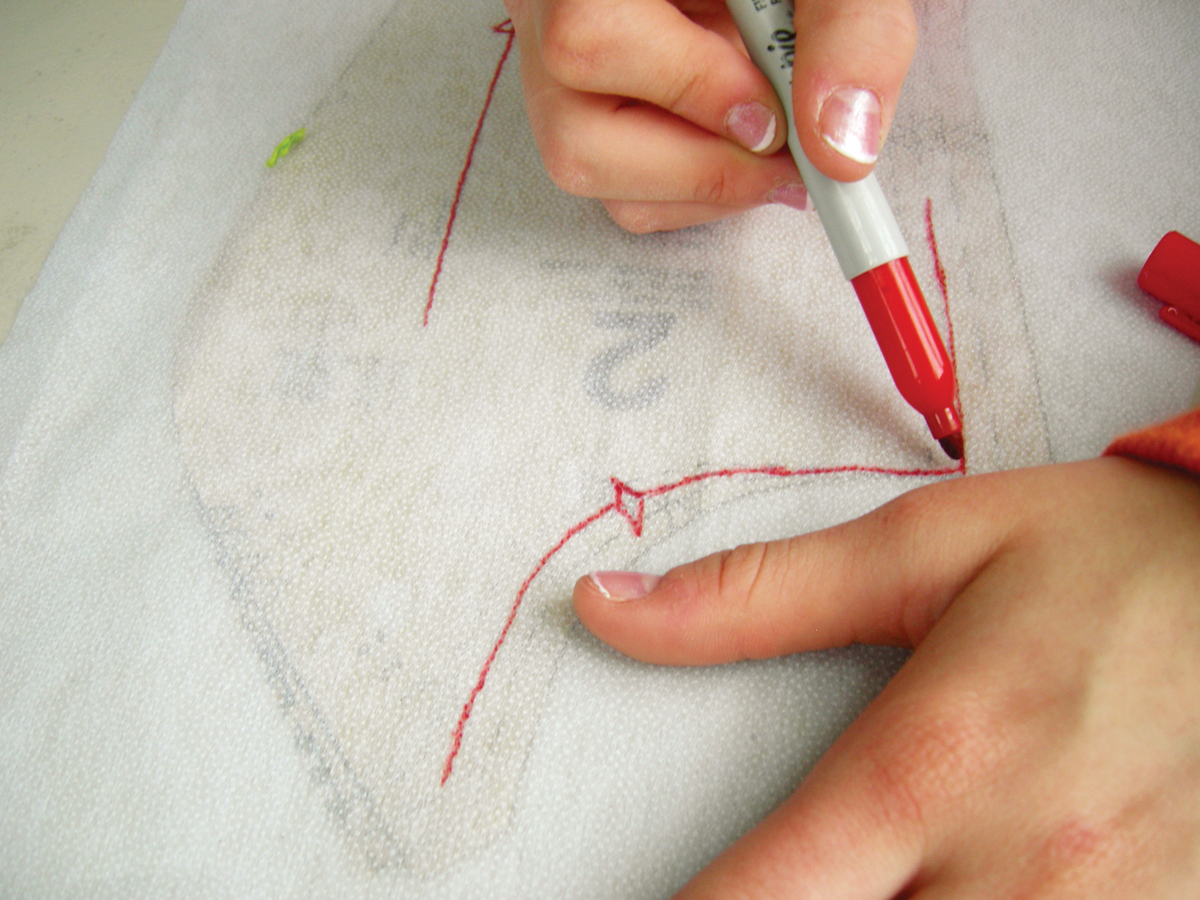

For this project, we used plain weave — over 1 thread, under 1 thread. By using different yarns to provide color and texture, you can achieve great looks with this simple fabric structure. We ended up making a vest with our woven fabric, with the help of a commercial sewing pattern.