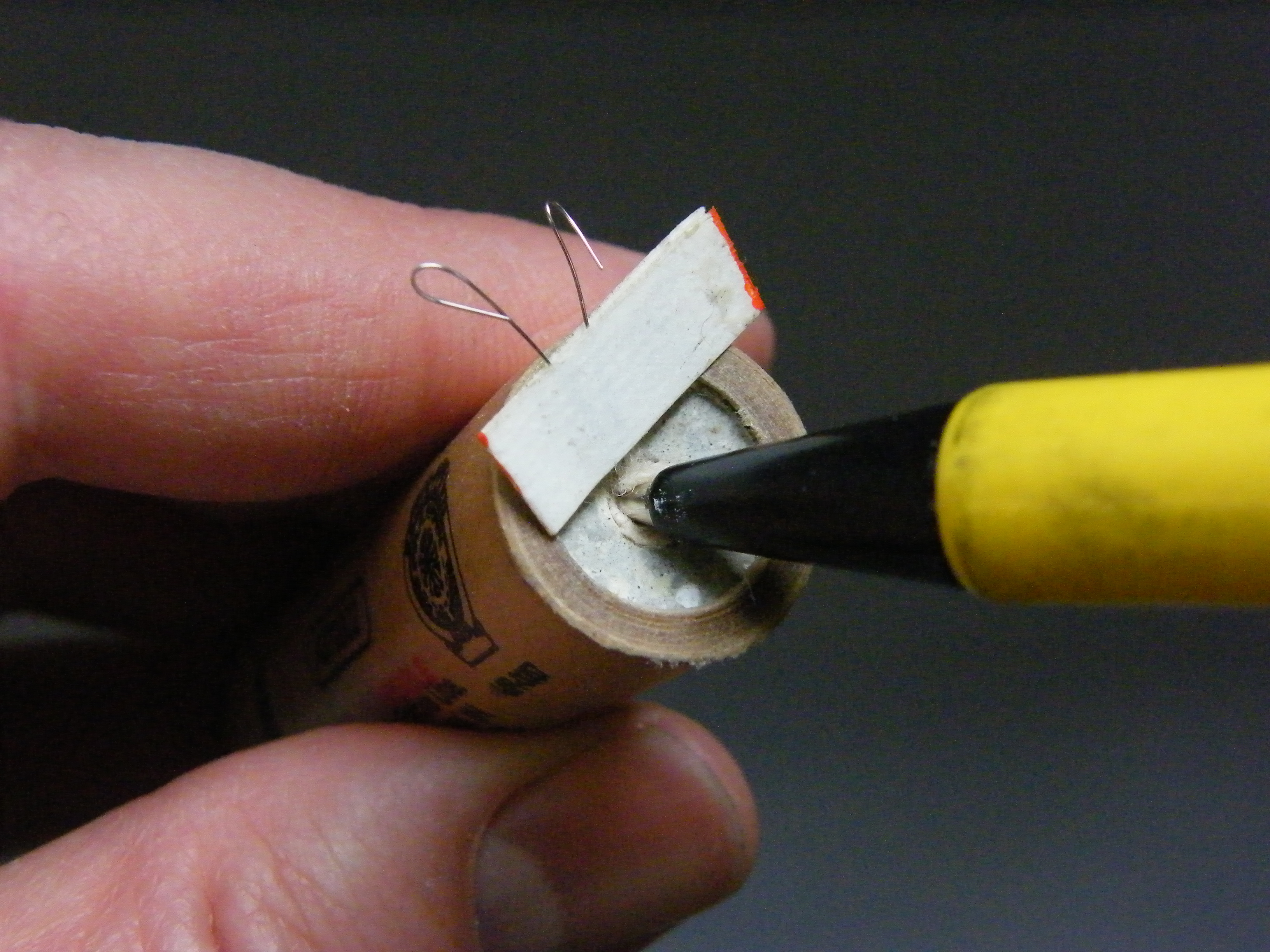

Modern commercial igniters can send a rocket soaring with just a touch of current. When inserted properly they’re very reliable. Unfortunately, they are fragile, and folks new to the hobby sometimes ruin them by inserting them improperly. Packs of spares are expensive, and not all outlets carry them. There’s a cheap alternative: hand-wound Nichrome igniters.

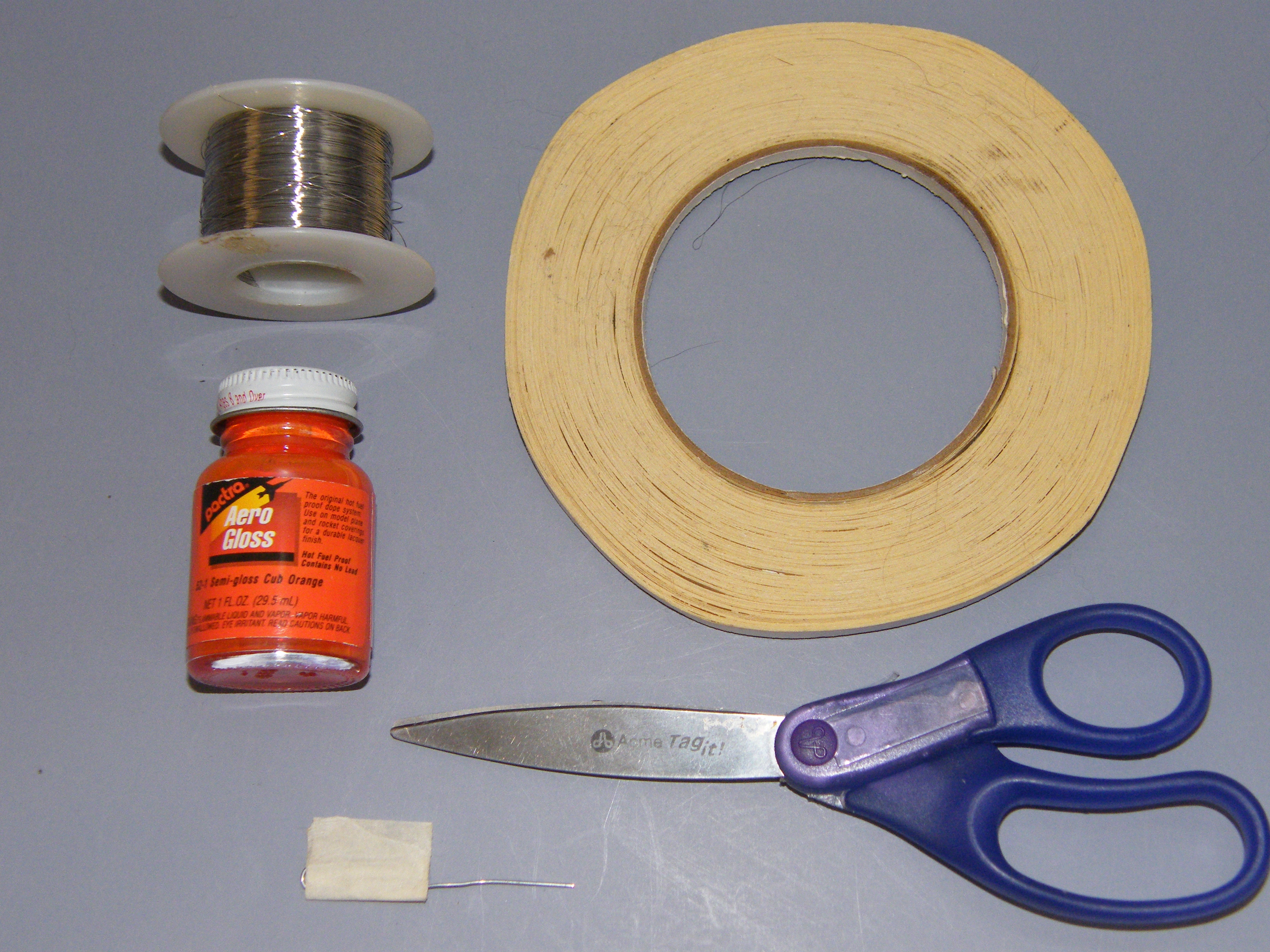

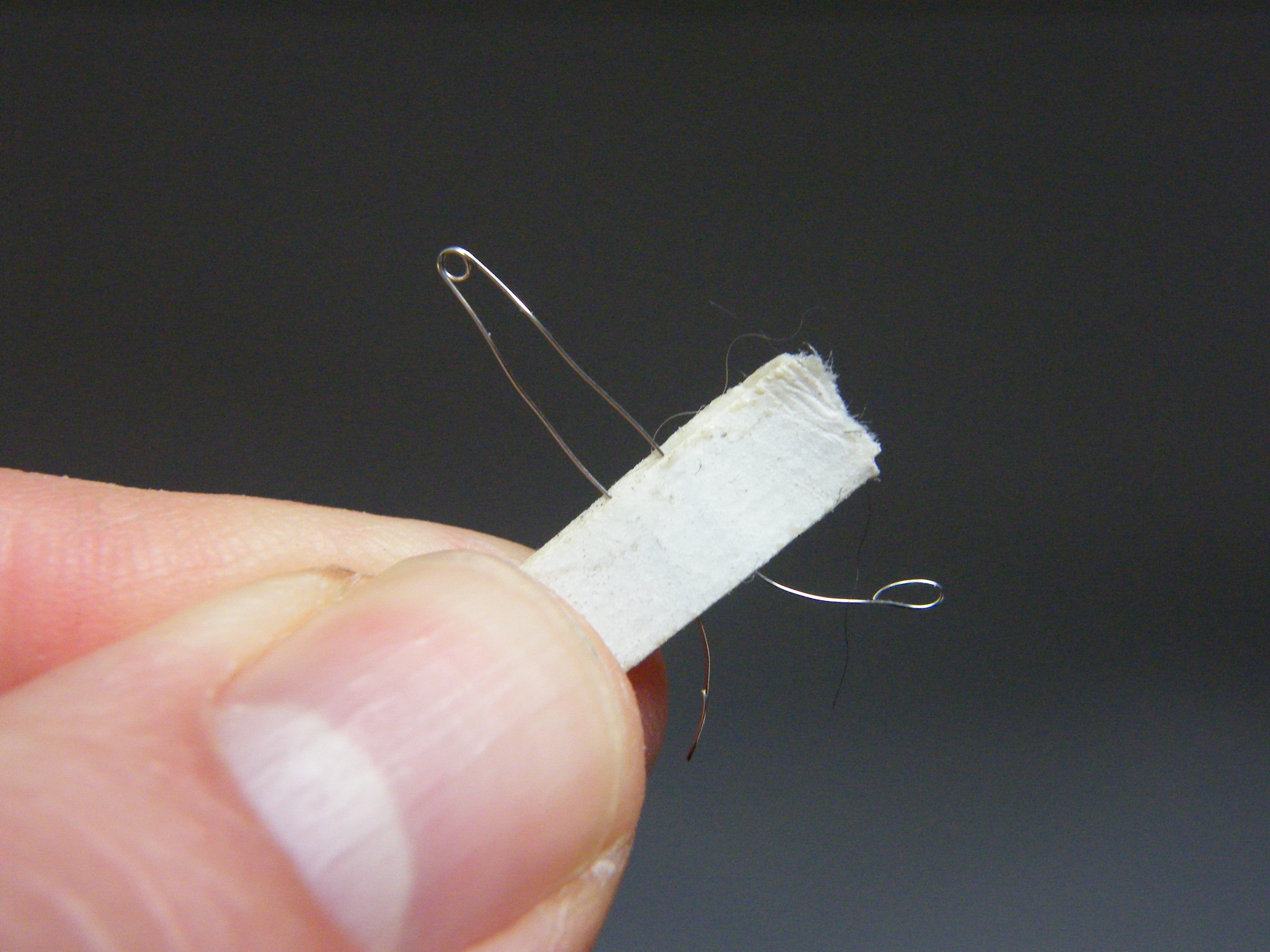

Nichrome is a high-resistance alloy. Run a current through it and it glows red hot. Until the mid ’60s rocket motors came with a length of the wire, which rocketeers cut and shaped into an igniter. If placed correctly they are very reliable. I enhanced the austere original design with a few tricks picked up from old newsletters and personal experience.

Nichrome igniters can only be used with black powder motors, and have one other drawback: they need a lot of current to work. This isn’t a problem if you’re using a 12V launch system powered by a car battery. But they’ll quickly suck the juice out of the alkaline AA cells or 9-volt batteries used in commercial launch panels. Plan accordingly by bringing extra batteries, or test your Maker chops by making a sturdy 12V launch system!