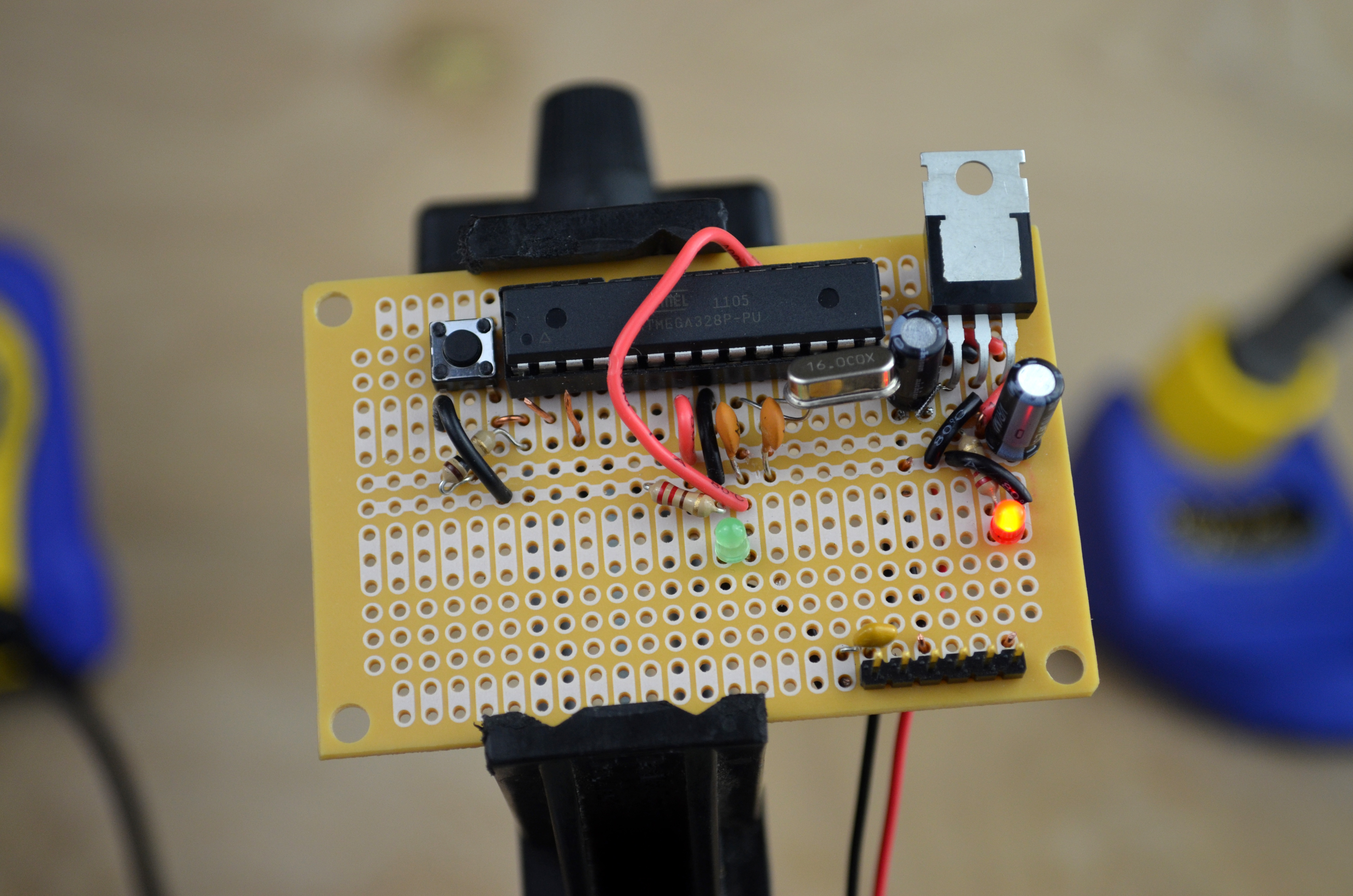

Place the second 10uF capacitor (seen behind the voltage regulator). We will use the center two rails, the “power rail,” which are connected lengthwise. You might not be thinking yet about layout design, but it’s important that you consider it.

Traditional component layout would place the IC centered on the board and surround the chip with support peripherals, such as the power regulation circuit we are building now. Traditions are great to know, but spanning a 28-pin IC over the only two rails of contiguous lengthwise connection is problematic for adding in more components later.

Not having the IC in the center of the perfboard is the first big component layout decision that effects the layout. Since all components in a layout influence each other, 28-pins is a lot of influence!

Note: Placing the IC off-center will also allow room for the 9V battery inside the tin, as mentioned in the introduction.