Growing up, I loved watching New Yankee Workshop on PBS. I was always so amazed by the many different projects the host was able to create. My favorite projects were always those created on a wood lathe. I didn’t think I’d ever have the chance to learn how to use a wood lathe, because my dad didn’t have one and his tools were the only ones I could access. When I got to college, I took a manufacturing class. As soon as I stepped into the wood shop, I noticed the giant wood lathe, and I knew I had to learn how to use it. Although I learned how to make a few different things with it, I never had the chance to make anything for fun.

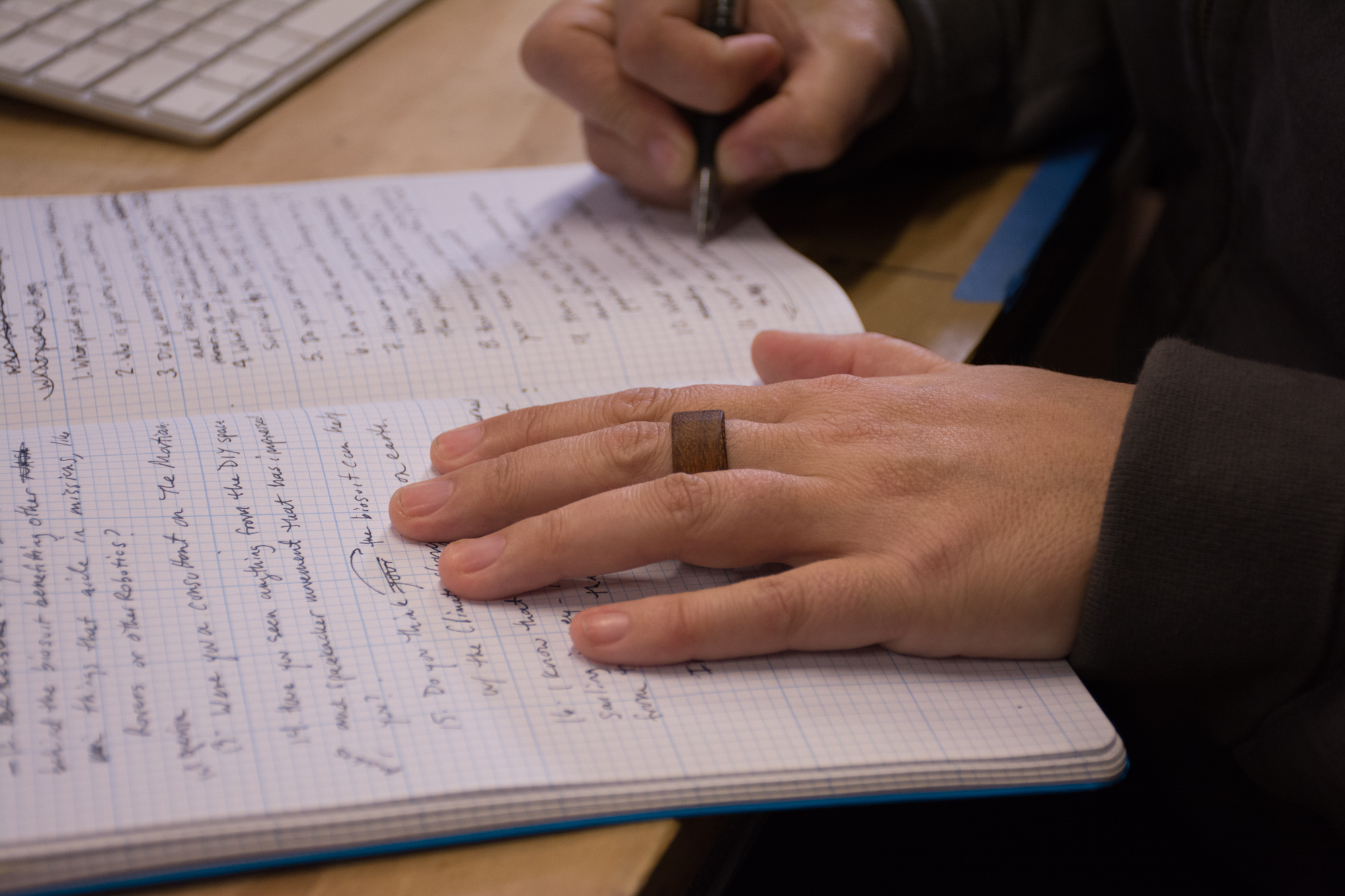

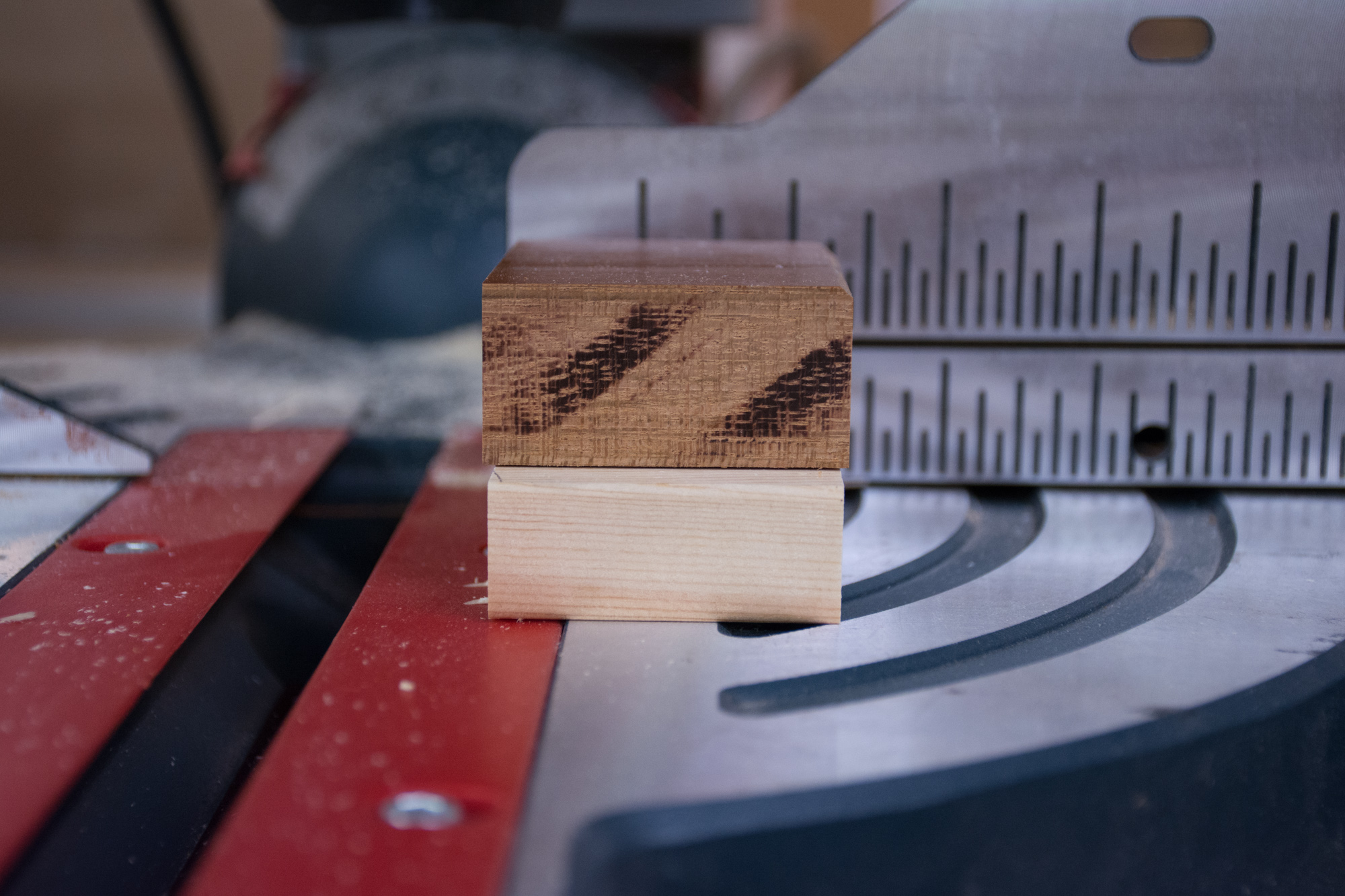

I no longer have access to a lathe, but I still wanted to make a wooden ring. I looked all over the internet to see if there was a simple way to do this, but I couldn’t find anything that was as simple as using a drill press. I didn’t add any inlays or any other types of decorations (I just wanted a simple band); however, I can’t imagine it would be difficult to add to this simple design.