Sometimes nothing is as important as perspective. My goal in photography is often to find a view no one else has found, to be able to see things from unusual and insightful vantage points.

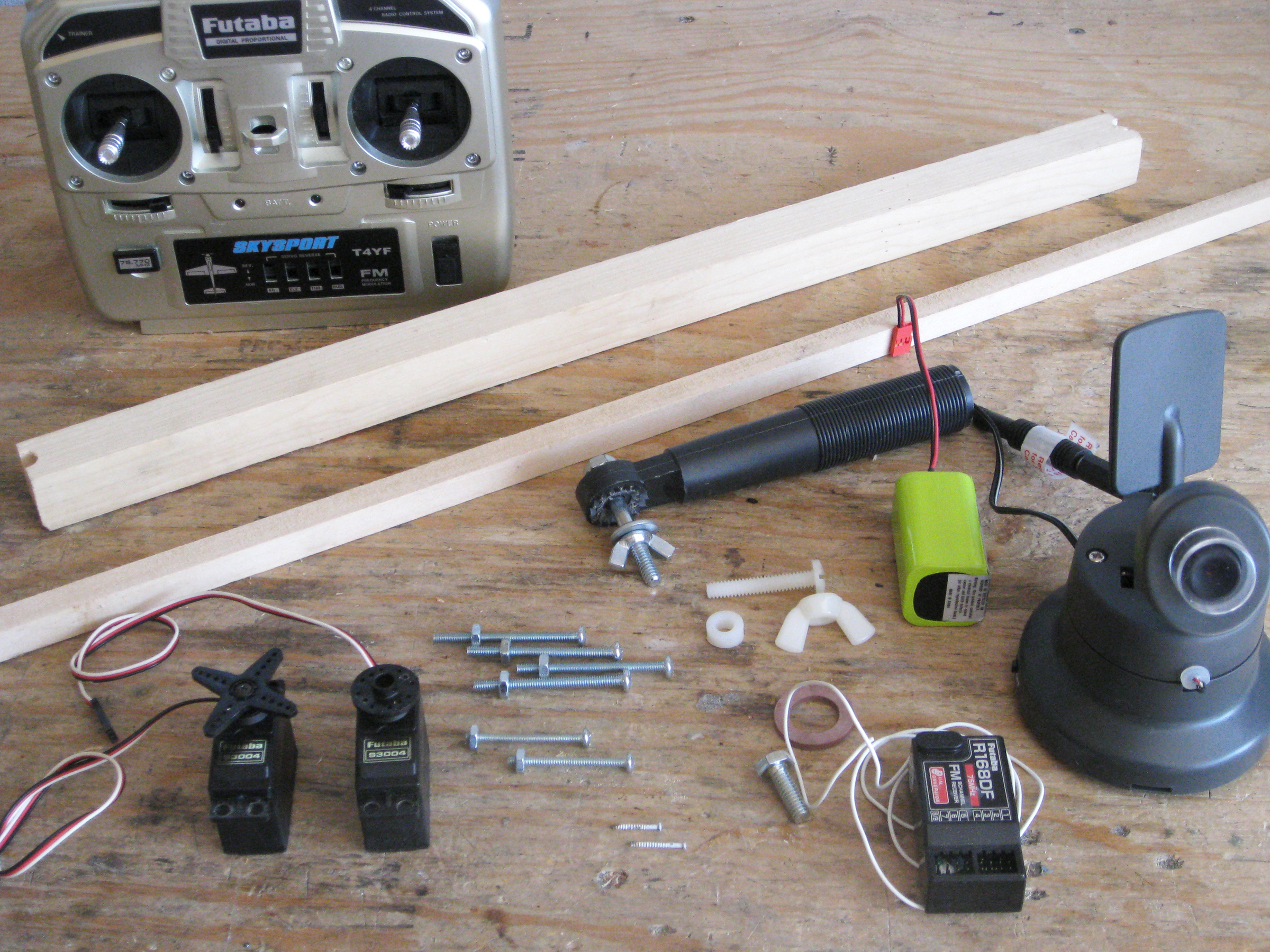

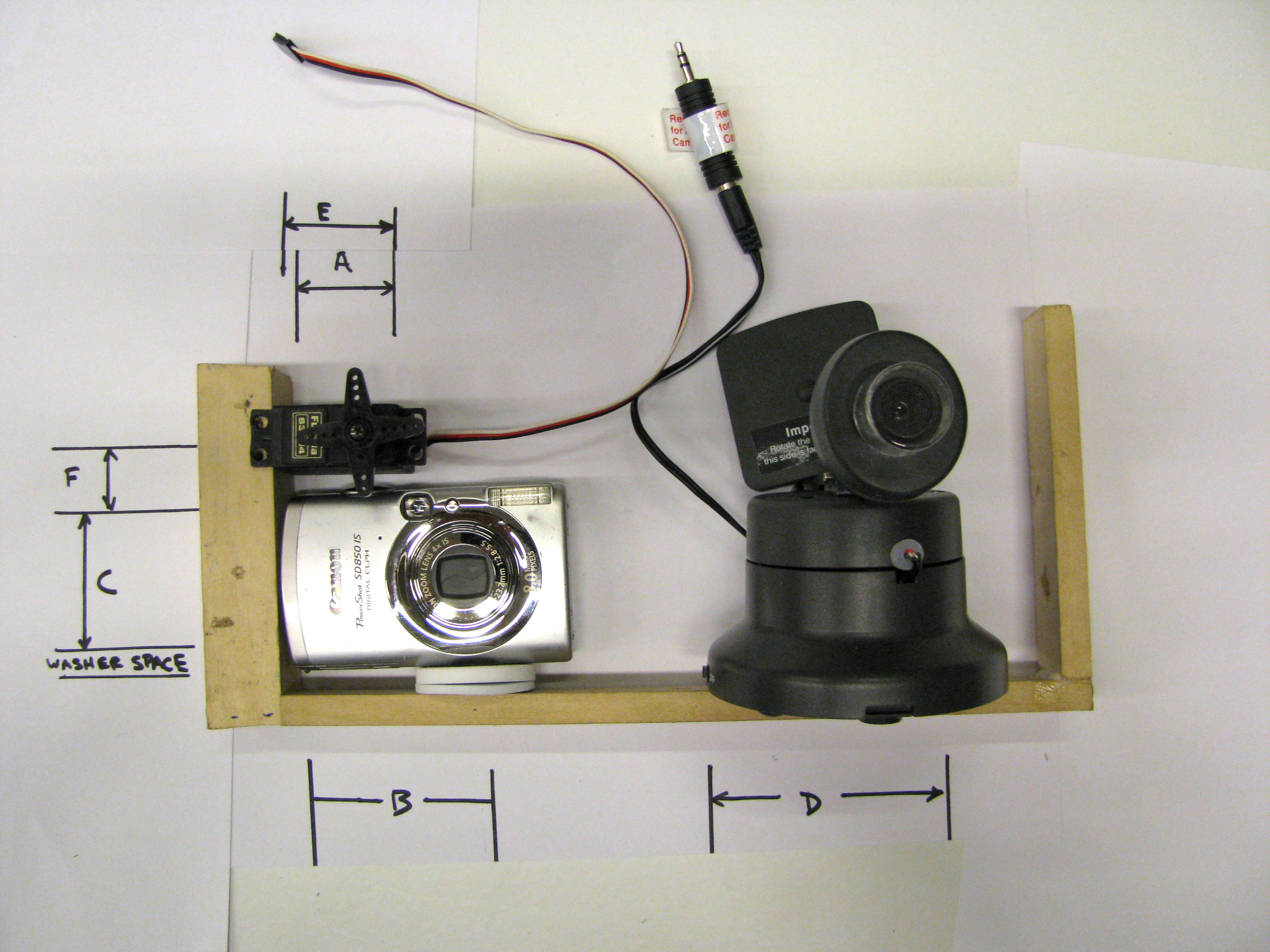

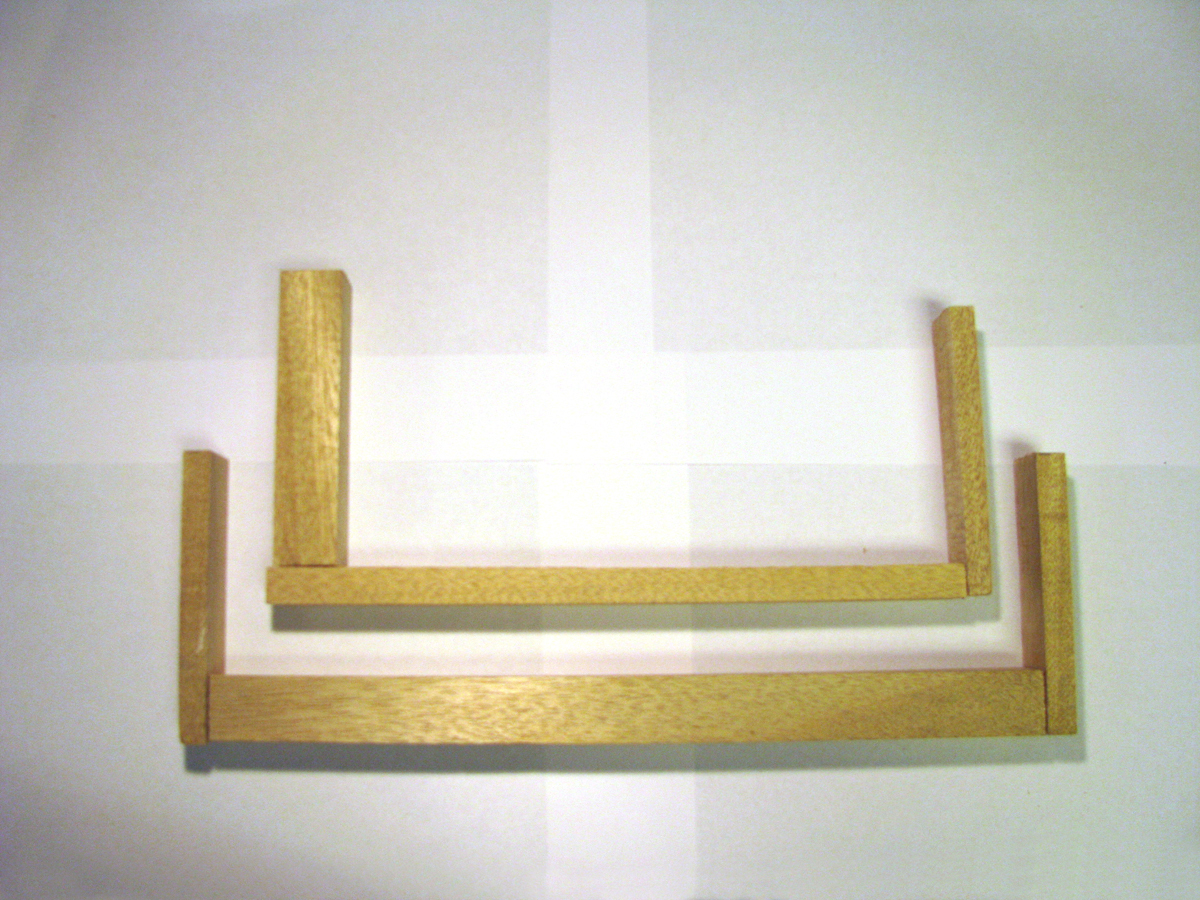

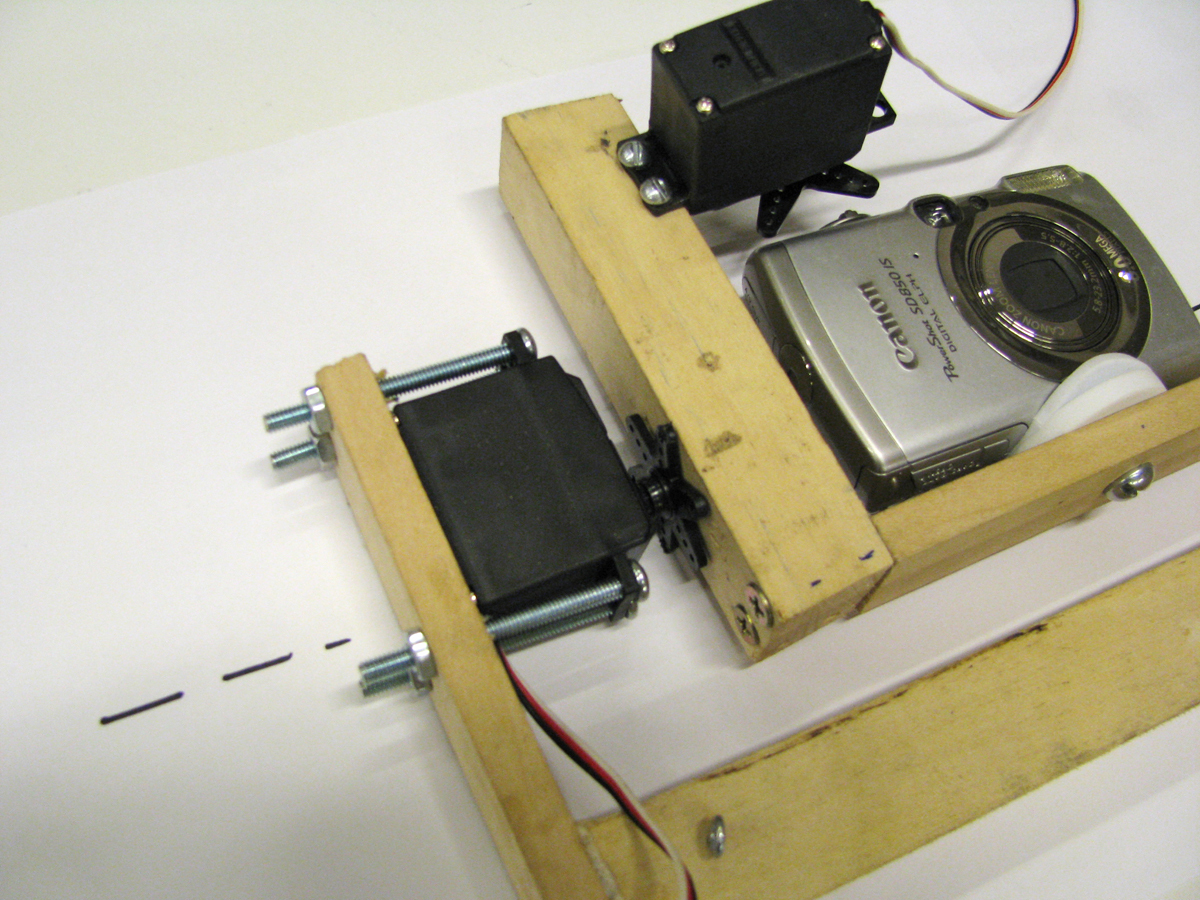

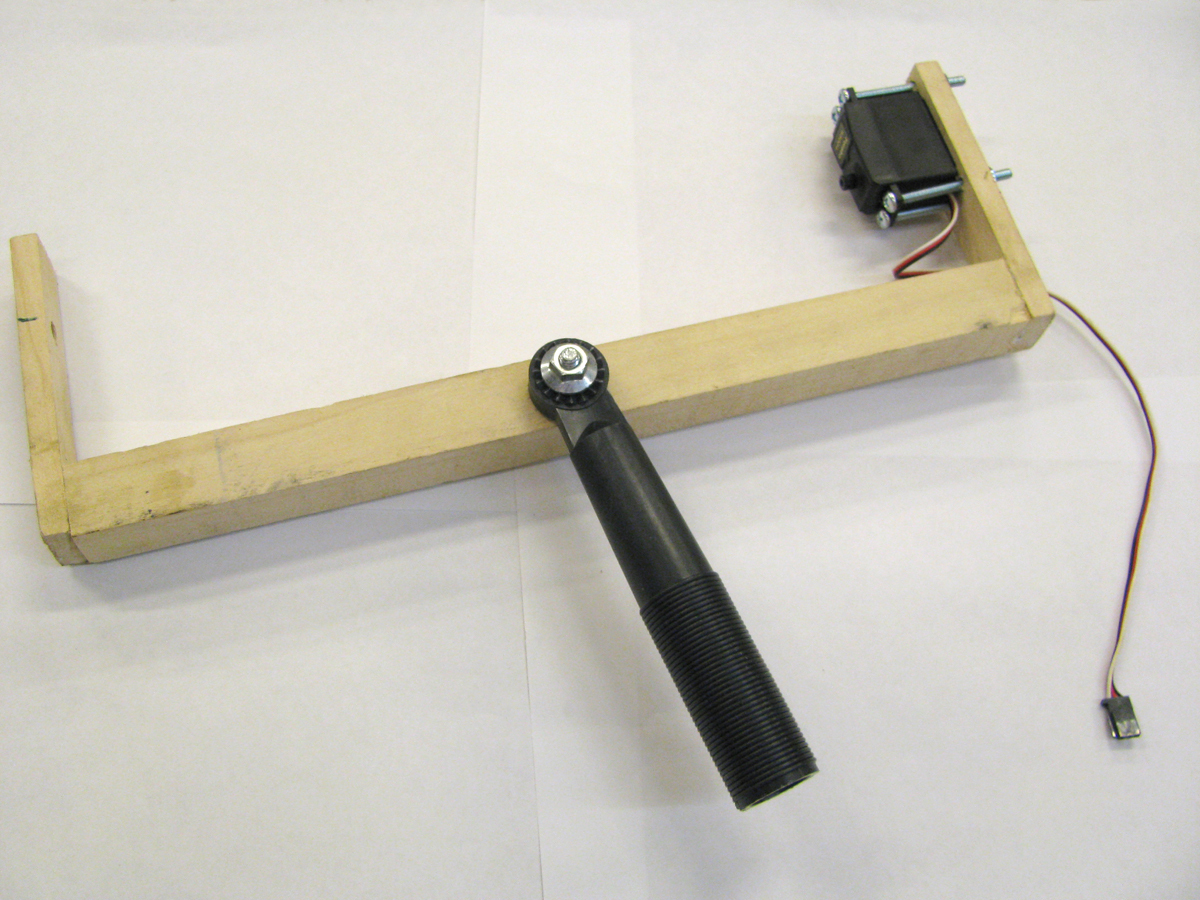

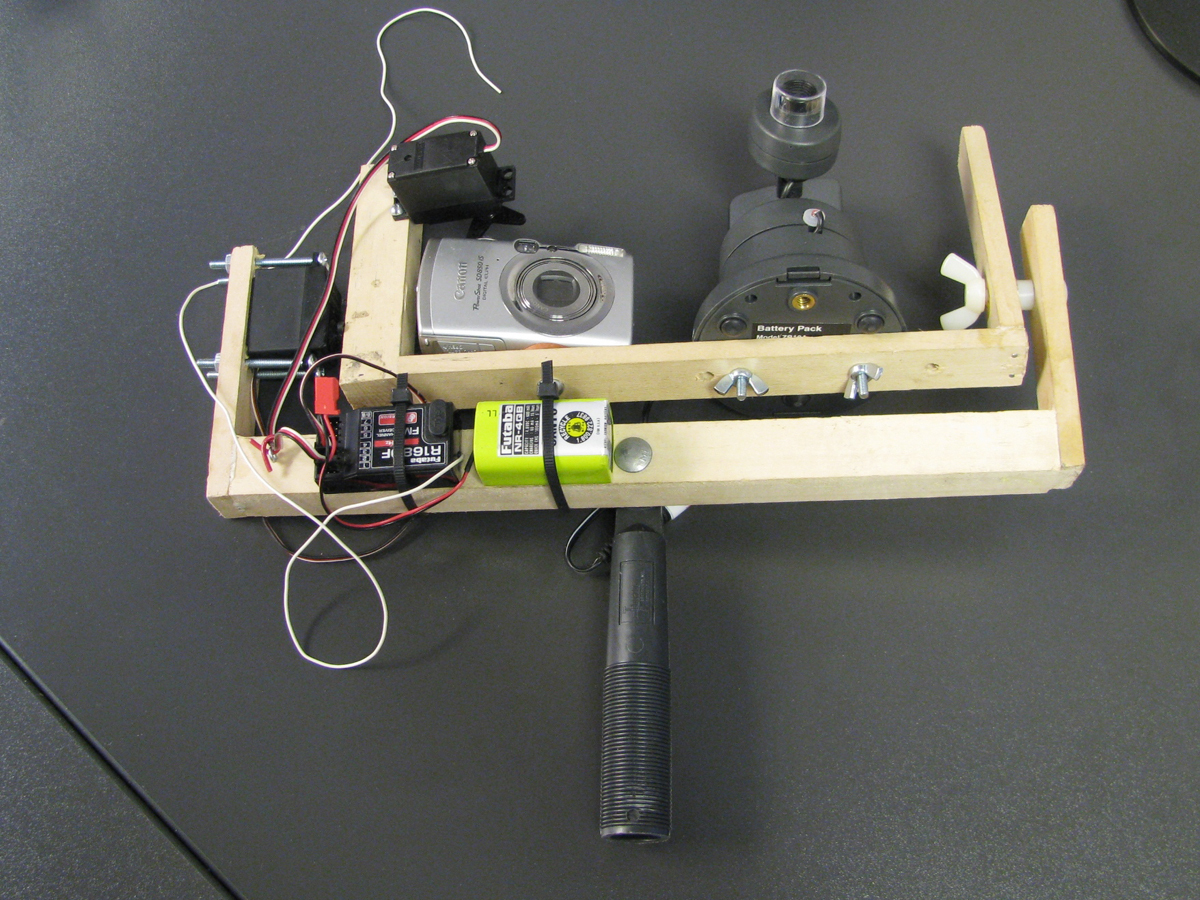

The most practical way to obtain the elusive aerial perspective is by attaching a camera to a mast. While not trivial, it’s not complicated, either. Making a mast-mounted camera rig like the Sky Eye takes about a day, not including trips to the store. You can make the rig and use it the same day.

I’ve experimented many times with aerial photographic techniques for obtaining the much-sought-after bird’s-eye view. First, there was the specially rigged kite, way back in the first issue of MAKE (Volume 01, page 50, “Kite Aerial Photography”). And I’ve dabbled with taking pictures from R/C aircraft, helium balloons, model rockets, and so forth.

While these approaches are novel, I find them limiting because the photographer is at the mercy of uncontrollable factors. There may be too much wind to loft a balloon, or not enough to fly a kite. Rough terrain or low visibility may make it impossible to launch and recover a rocket-borne camera. And none of these methods works indoors, say at a stadium. The Sky Eye works in all these conditions.