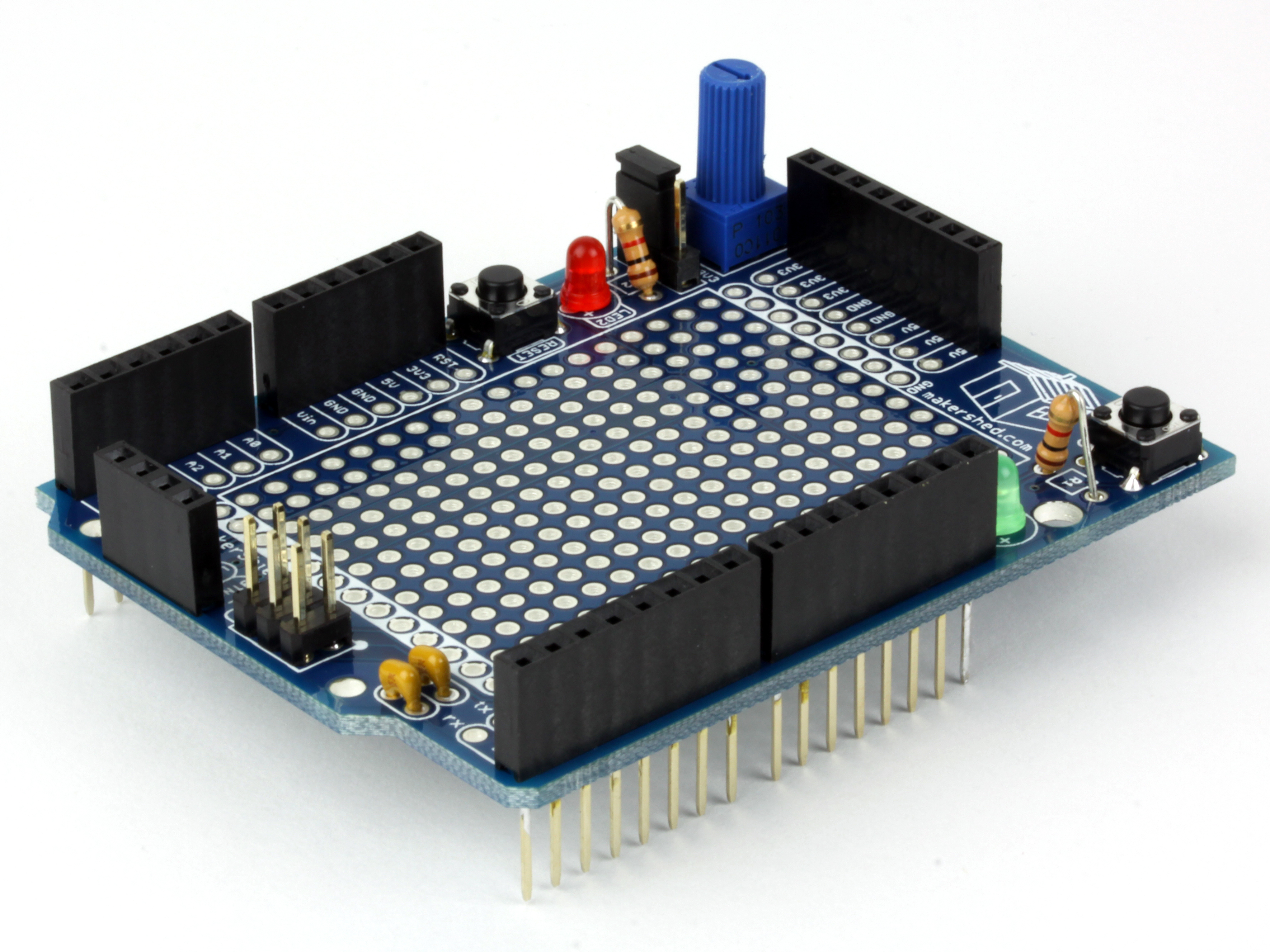

If you aspire to do more than blink an LED with your new Arduino or Netduino, you need a prototyping shield that allows you to build a circuit. After listening to our readers and customers, we created a new kind of prototyping shield that supports the needs of noobs as well as advanced users. Introducing MakerShield!

Unlike conventional prototyping shields, Maker Shield lets you create circuits the way you want, and easily change them without having to solder. All of the MakerShield’s major components and pins are user-assignable, allowing you to jump from any component header pin to any pin on the microcontroller. Make all the changes you want. Just jump and go!

The MakerShield’s potentiometer lets you switch between 5V or 3.3V signals, so the growing numbers of Netduino users can use MakerShield too.

Being able to change the pins connected to the onboard LEDs, button, and potentiometer allows beginners to learn Arduino software with ease, while more advanced users will appreciate the convenience of the onboard components, the incredible flexibility, and the ability to stack another shield on top — the MakerShield uses stackable header pins and retains the original ICSP pin locations of the Arduino.