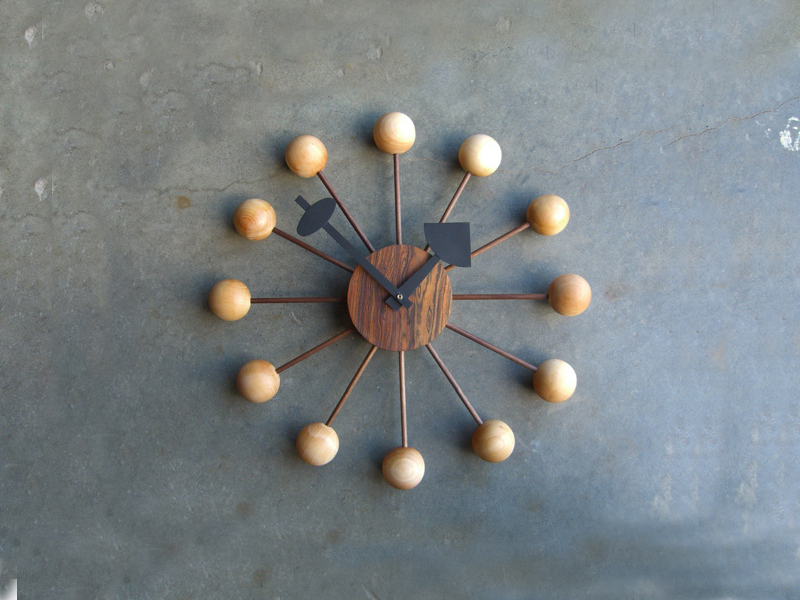

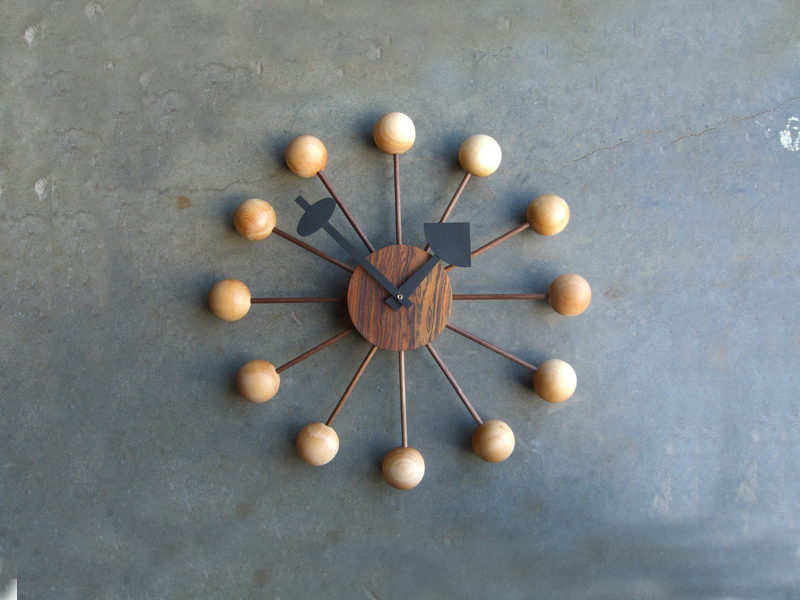

The George Nelson ball clock is a neat little slice of mid-century art and architecture, but with the current licensed reproduction selling for around $265, I decided that if I were going to have one, it would have to be an unofficial version.

I made my first ball clock as an exercise in learning how to use a MIG welder, and ended up with a double-sized, welded-steel version of the clock. I was excited when asked to write this how-to piece, but realizing that most people probably don’t have access to welding equipment, I decided to create a new ball clock that could be put together with all wood parts and assembled Tinkertoy style.

Conveniently, I found that I was able to gather up all the supplies for the clock with a single stop at a Rockler woodworking store, or a session on their website (http://rockler.com).