CAUTION: This project is a non-weatherproof adapter box for 240V. It is not intended, nor should it be used in wet weather or as a permanent installation. Weather-rated parts and ground-fault circuit interrupter (GFCI) components must be correctly and consistently used for outdoor use. Do not consider anything that you learn by reading this project sufficient to perform permanent electrical work like adding breakers, circuits, or outlets. Electricians have to put in tens of thousands of hours on the job to get their licenses for good reasons. Use a licensed electrician for any new electrical installations or modifications to existing wiring or circuits and have the work permitted and inspected according to your local codes and regulations. Use the information and instructions contained in this project is at your own risk.

When I bought a 240V MIG welder and its plug didn’t fit my 240V AC outlet, I went online and bought a custom adapter for it.

When I bought a 240V plasma cutter with a different plug, I bought a different adapter.

When I bought my 240V TIG welder and the problem emerged again, I knew it was time to think like a maker, not a consumer, and build myself a general solution to my problem.

There are a huge number of 240V plug/receptacle configurations approved for use in the United States. Other than the world of 3-phase power (which is outside the scope of this project), all of them provide various combinations of 2 hot wires, a neutral wire, and a ground wire. Each of them is rated for a specific amperage. Some are locking and some are straight plugs. My recent skill builder in Make: magazine, “Understanding 240V AC for Heavy Duty Power Tools,” provides a deep dive into the world of 240V, and I hope everyone interested in working with high voltage will read it and expel the surprising number of urban myths and misconceptions that surround this powerful resource.

240V is intimately related to the 120V we know and love for the majority of our AC electrical needs. Some, but not all, configurations of 240V receptacles provide the wires required for breaking out 2 independent 120V circuits. Since my access to 240V is a weatherproof RV style outlet near my driveway, my welding, cutting and grinding occur outside as well. I don’t have a 120V outlet outside, so there is an electrical cord running through my dog door whenever I’m working. This didn’t make anyone happy, so when I decided to fix my 240V adapter problem, I wanted to include 120V outlets as well.

Before we get started, let’s talk about amperage. When considering amperage, think about it in terms of how much is available (the circuit’s rating,) and how much might be used. If you connect a tool that draws 45A to a circuit rated for 30A, ideally you’ll trip the breaker. But you’re also likely to be pulling more current through the circuit’s wires and components than they are rated for until the breaker trips. People rarely run wire rated for 55A on a 30A circuit. If the breaker fails or is slow to trip, you’ll be attempting to turn the wires in your walls into heating elements. Always use equipment rated appropriately for the ampacity of the circuit you’re plugging into.

High amperage circuits are a little bit like being handed enough rope to hang yourself. If you have a tool rated to use 25A, it usually has a 30A rated plug. If you use an adapter to connect this to a 50A circuit, you’ve possibly put your tool at risk. If something happens that causes the tool to draw 45A, the tool and its plug may begin to overheat as their current carrying capacity is exceeded. The tool expects to have a 30A circuit breaker upstream of it, to protect against this. But the 50A breaker thinks everything is fine and will happily continue to overload the poor tool.

The bottom line is to always use components with appropriately matched ampacity. As you’ll see in this project, when we want to make an adapter to connect a 30A plug to a 50A outlet, we add a 30A breaker in line. When we want to split out 120V circuits from the 50A outlet, we have 15A breakers on each 120V circuit so that 50A isn’t made available to the tools we plug in.

Designing the Adapter

As much as I’d like to have a “universal” adapter, the reality is that there are too many possible configurations to support. I’ve decided to support the set of plugs that my current tools use and get two 120V circuits in the bargain. I’m connecting the adapter to a 14-50R 50A RV outlet which provides sufficient amperage and wiring for my requirements.

So the plan is…

Input:

- 14-50P 240V 50A plug

Outputs:

- (1) 6-50R 240V 50A receptacle

- (1) 14-50R 240V 50A receptacle

- (1) L6-30R 240V 30A receptacle

- (2) 120V 15A power strips with breakers

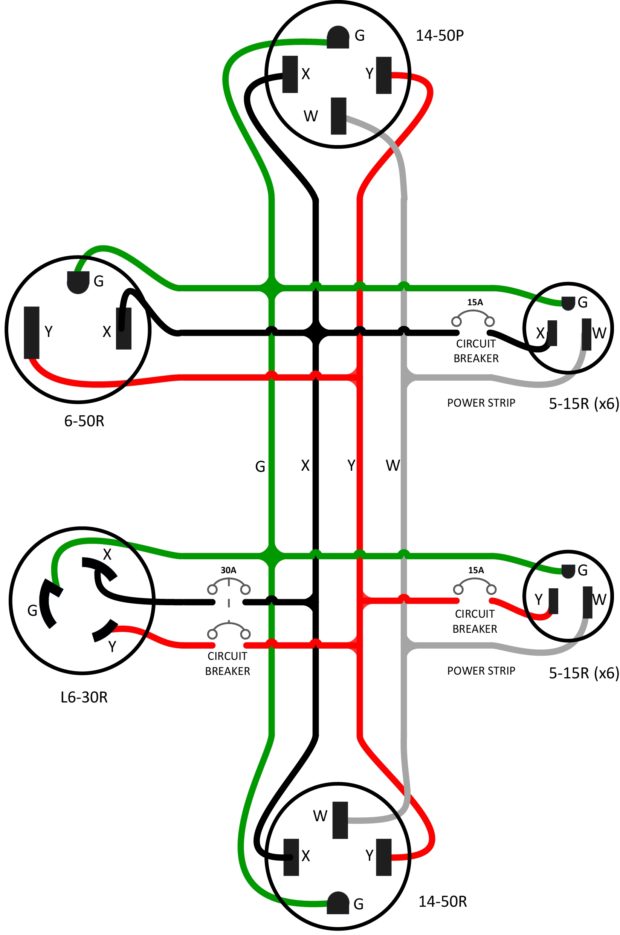

You may want to draw power from a different kind of connector, or you may need different outlets. Please read my accompanying Skill Builder, “Understand 240V AC for Heavy Duty Power Tools” to get a better understanding of how to safely modify this project for other connectors. For this project’s connectors, the relationship is straightforward (see Figure 2).

If we rearrange that diagram a little, we can derive the schematic for this project. It’s pretty simple, at least compared to the printed circuits I build. (See Figure 3)

Power comes in through the 14-50P and we get two hot wires (X & Y), a neutral wire, and a ground wire. 240V is available between X & Y and 120V is available between either X or Y and neutral. All these outlets (and all current NEMA 240V connectors) provide ground — it’s an emergency return path for current if something fails. The L6-30R, locking 30A outlet, has a 240V 30A dual circuit breaker protecting it (E3) (see Figure 4). As noted, I’m using 120V power strips that each have an integral 15A breaker (E2) (see Figure 5.)

Since we need to do a considerable amount of wiring and mount the circuit breaker, I’ve used a “70 Amp 2-Space 4-Circuit Indoor Main Lug Load Center with Cover” (C1) (see Figure 6.) This is a metal box designed to hold two circuit breakers, or one dual breaker. It has mounts for a ground bar (E1) and knockouts we can use to attach our receptacles and incoming plug.