This project first appeared in MAKE Volume 38, on pages 76–77.

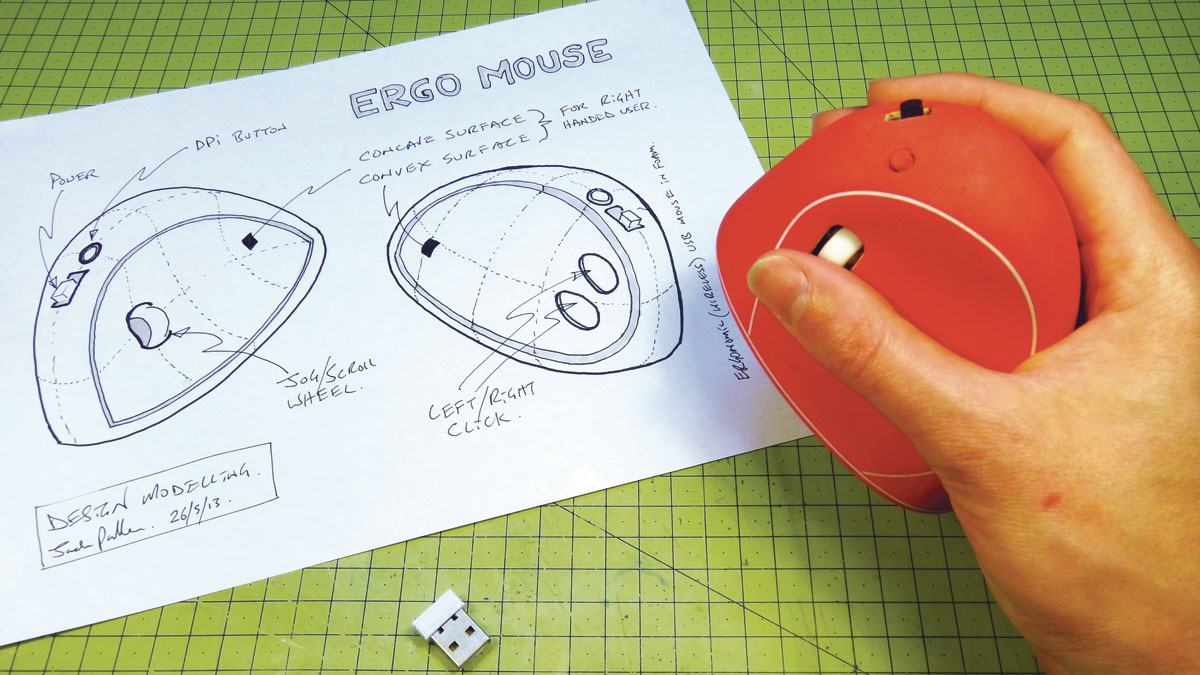

The Ergo(nomic) Mouse was originally developed as part of my Design Modelling online tutorials, to demonstrate ways to work with styrofoam modeling foam. However, it quickly evolved into a more complex project detailing how to “Frankenstein” a wireless mouse PCB to put the controls where the user wants them, and how to finish the foam with various surfaces, including a first: creating “Sugru skin.” Instead of spray-painting, this technique gives your models a novel, tactile finish using the popular air-curable, moldable silicone rubber.

Here are some of the steps involved in creating the Ergo Mouse. Read the complete Skill Builder online and you can use these techniques however you like!

Health and Safety

When sawing and sanding foam or fillers, use a particle mask or respirator for protection — small airborne particles are dangerous. When working with wet fillers, the fumes can be harmful, so use good ventilation and a mask that protects against fumes.

One of the safest all-around respiratory filters is 3M’s 7500 series multi-purpose “half-mask,” with cartridges such as 3M’s 6059 (ABEK1 rated) or 60926 (NIOSH approved), which protect you against particles and against organic and inorganic solvents.Please read the warnings on whichever products you intend to use.

Gloves are recommended when working with fillers and Sugru, and close-fitting goggles are also a good idea to keep particles and fumes out of your eyes and protect you against splashes of chemicals and glues,or even shattered knife blades.