So it doesn’t snow enough where you live? Fear not — if it gets cold, you can cover that front lawn in white, fluffy snow with your own homemade snow gun. All you need are a few items from your local hardware store, some quality spray nozzles, and access to a pressure washer and an air compressor.

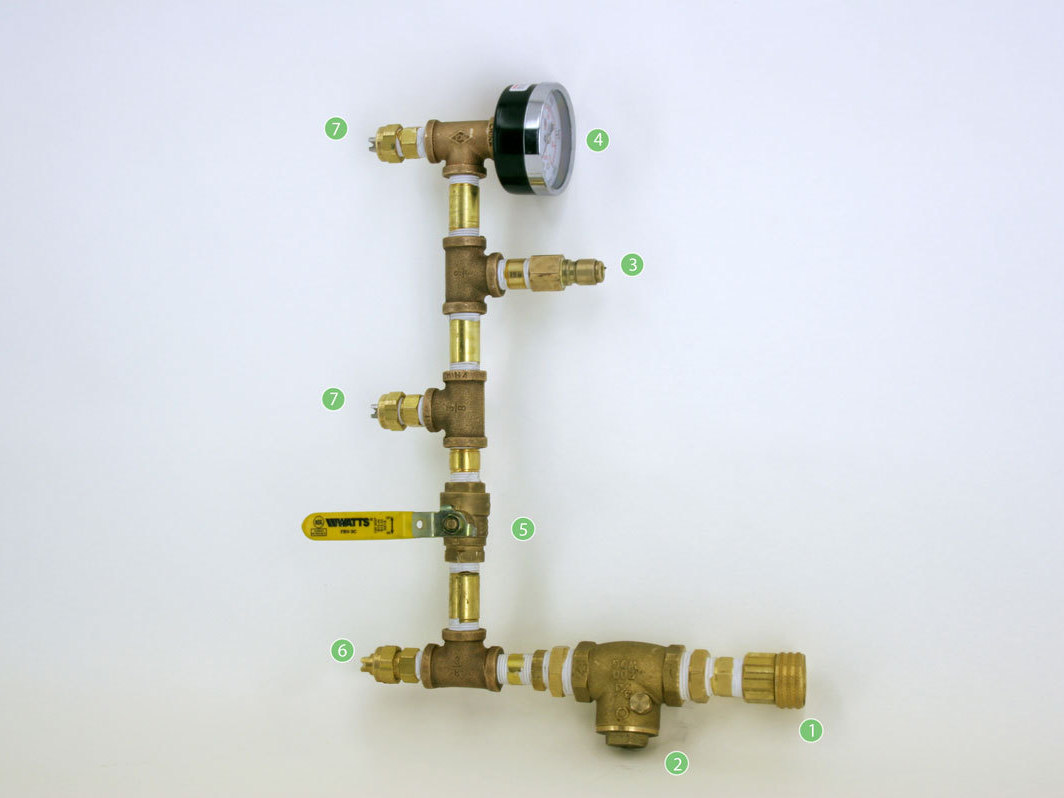

This snow gun is based on an internal-mixing “combo” design I found at http://snowguns.com. It mixes pressurized air and water internally and sprays them out through 2 types of nozzles that work together cleverly. Just wrap teflon plumber’s tape on all the pipe threads, then twist it together tightly as you see it in the diagram.

To understand how it works, remember high school chemistry: the smaller a particle is, the more surface area it has relative to its volume. Generally, that makes it easier to freeze. This is the job of the nucleation nozzle; it breaks the water into very small particles, making it possible for them to “nucleate,” or freeze quickly around their own impurities, thus generating a spray of superfine ice crystals.

This “ice mist” then crosses the spray from the 2 bulk nozzles, which supply the bulk of the water for our snowmaking. Droplets from the bulk spray freeze to the nucleated ice crystals, creating fluffy snow.