This project is an excerpt from Rubber Band Engineer by Lance Akiyama. This book is all about taking common household items and making awesome things out of them. You can buy the book here on May 15th.

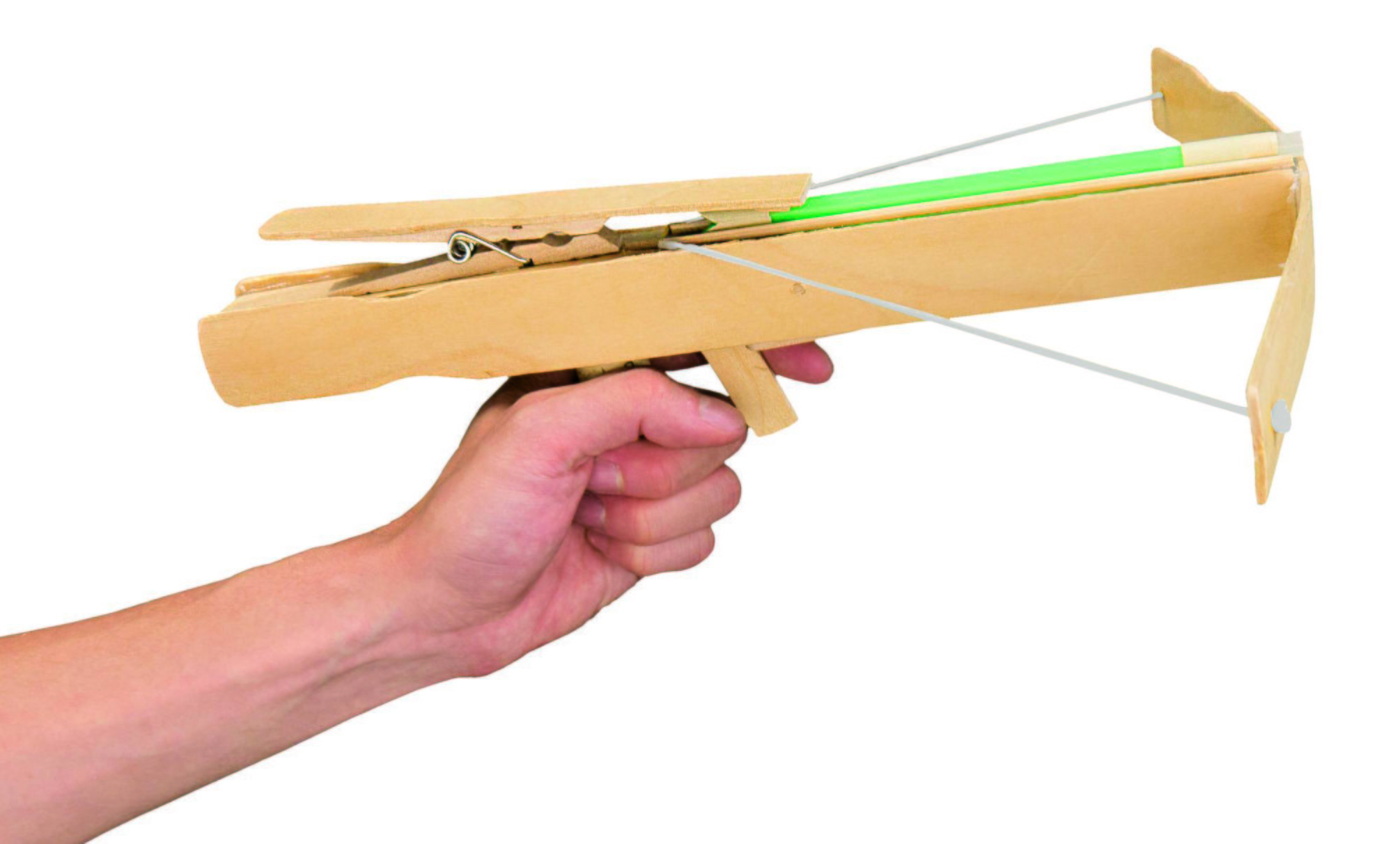

This project requires some determination to complete, but the payoff is worth it. The crossbow makes a satisfying snap when the trigger is pulled, and it can launch bolts more than 100′ (30m)! You can power this crossbow with a piece of string or with a rubber band.