Conclusion

Plugging In

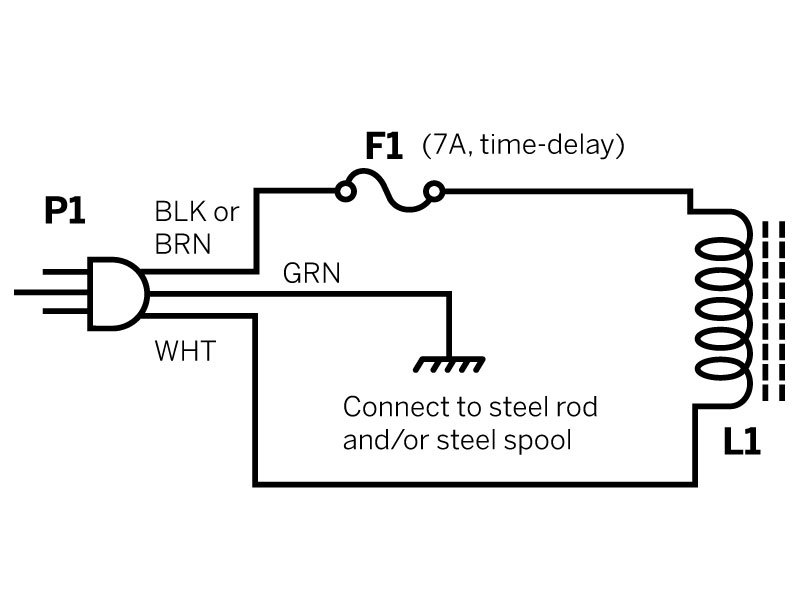

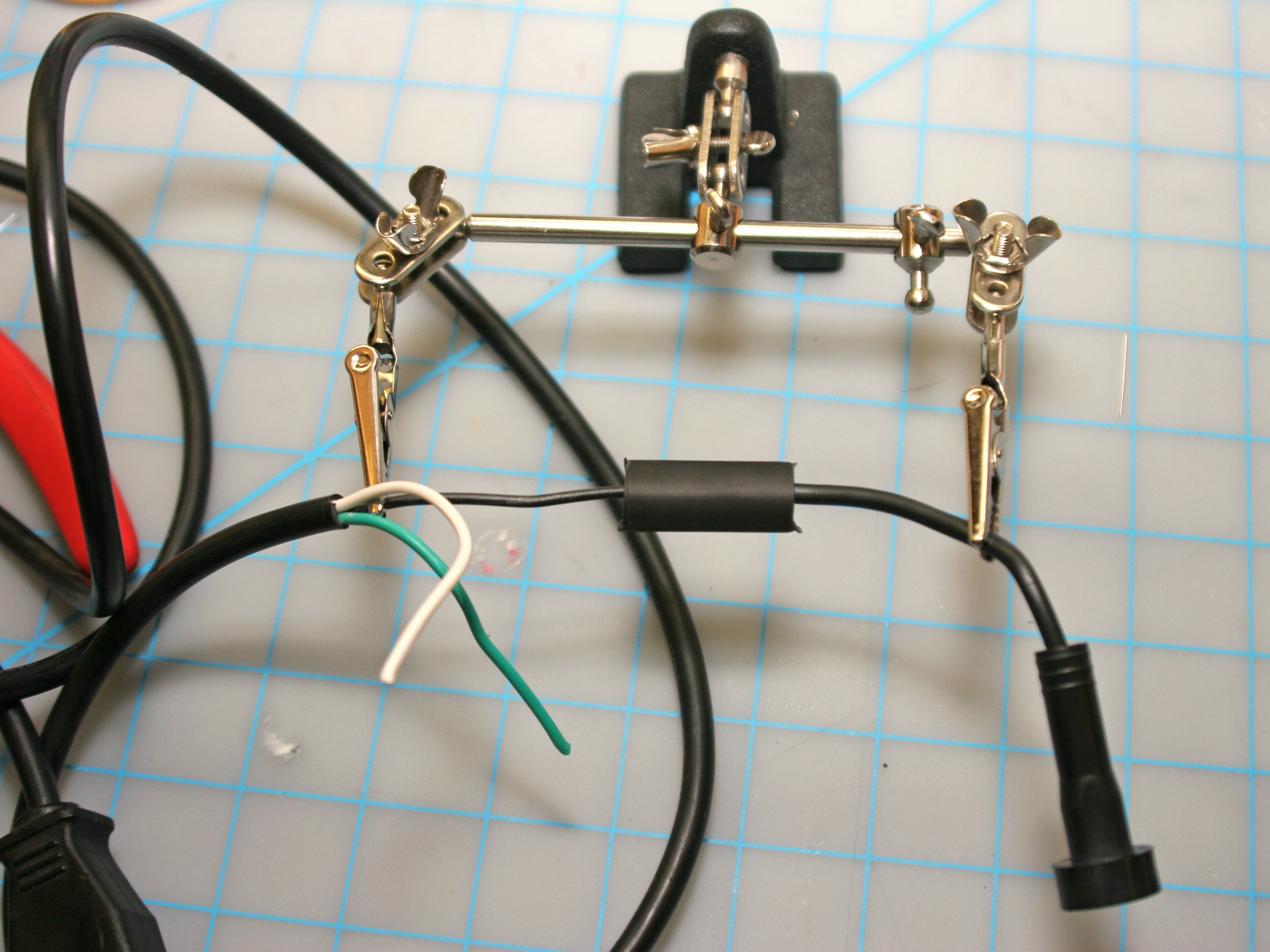

First, make sure any outlet you plug the power strip into is properly grounded. Test the AC voltage between the smaller, right (hot) slot and the bottom, rounded (ground) slot. It should read 110V–120V AC. If it’s outdoors, the outlet must be a UL-listed GFCI (ground-fault circuit interrupter) type. These outlets have test and reset buttons, and are often used where moisture might cause short circuits.

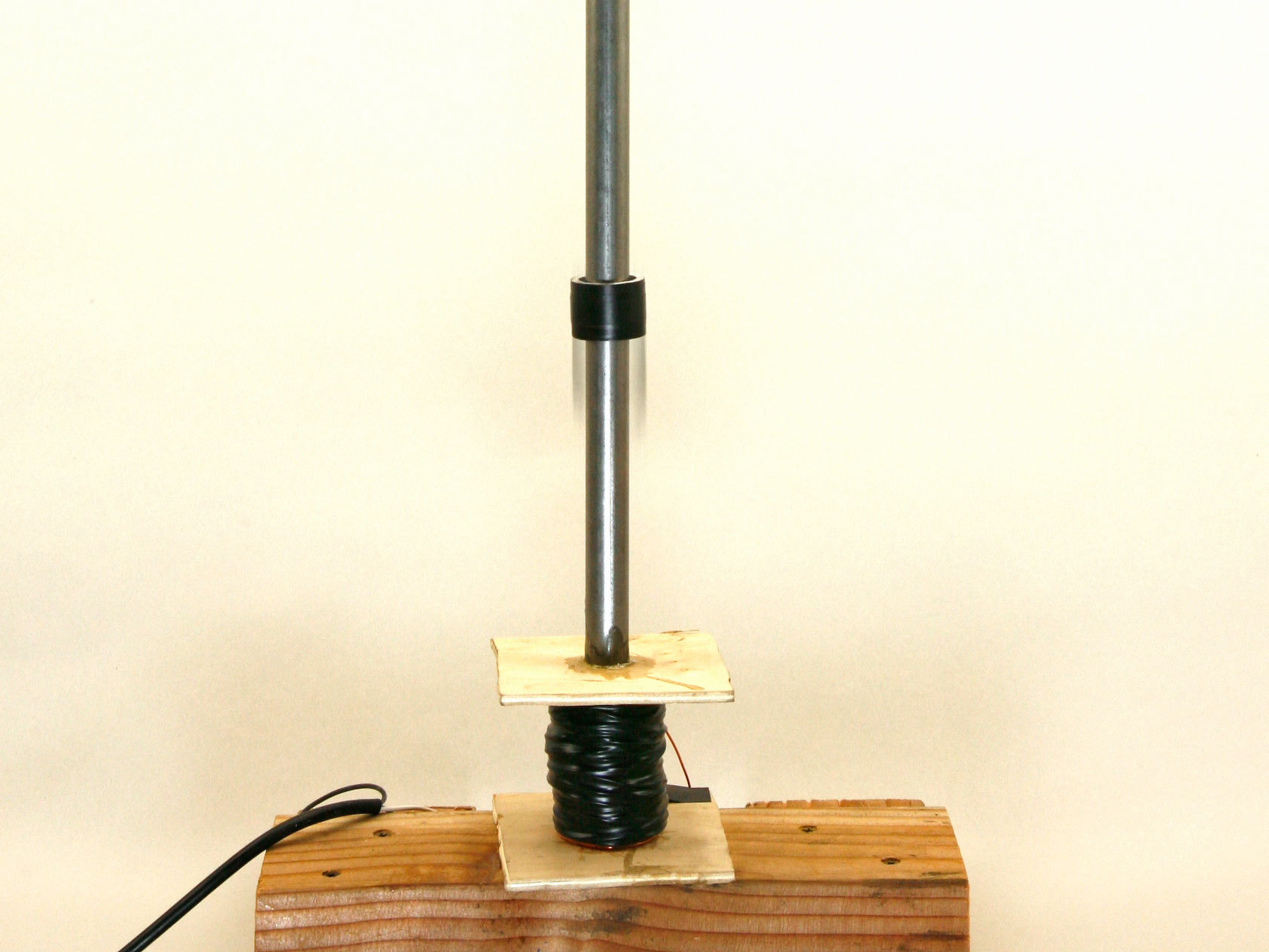

CAUTION: When setting up, place the stand a healthy distance away from the switch-operated power strip. This is why you used an extension cord at least 15' long. Also, place the stand on a high table or other flat, raised surface so that no one can look down over the rod and accidentally get hit in the eye.

Floating and Flying

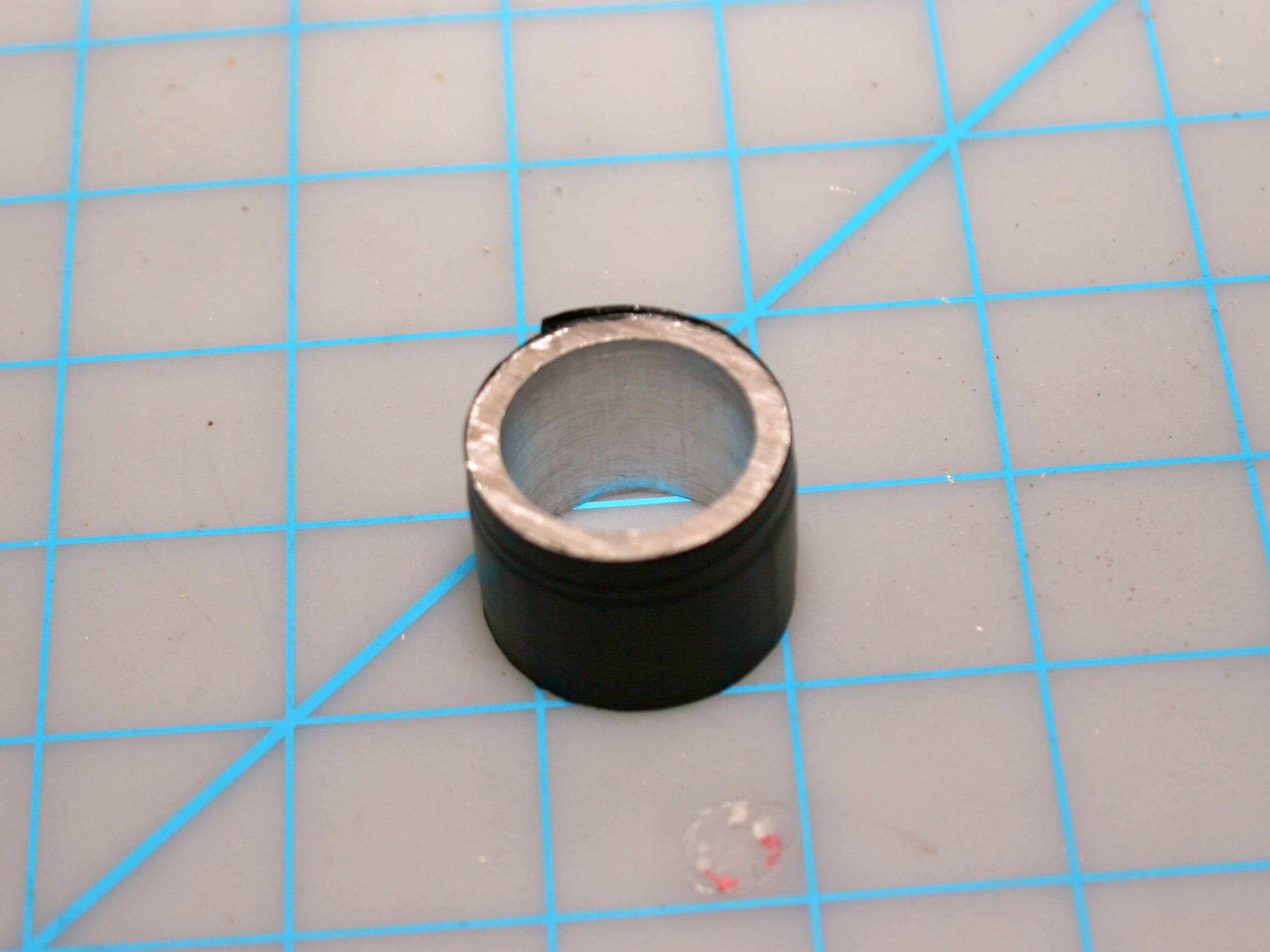

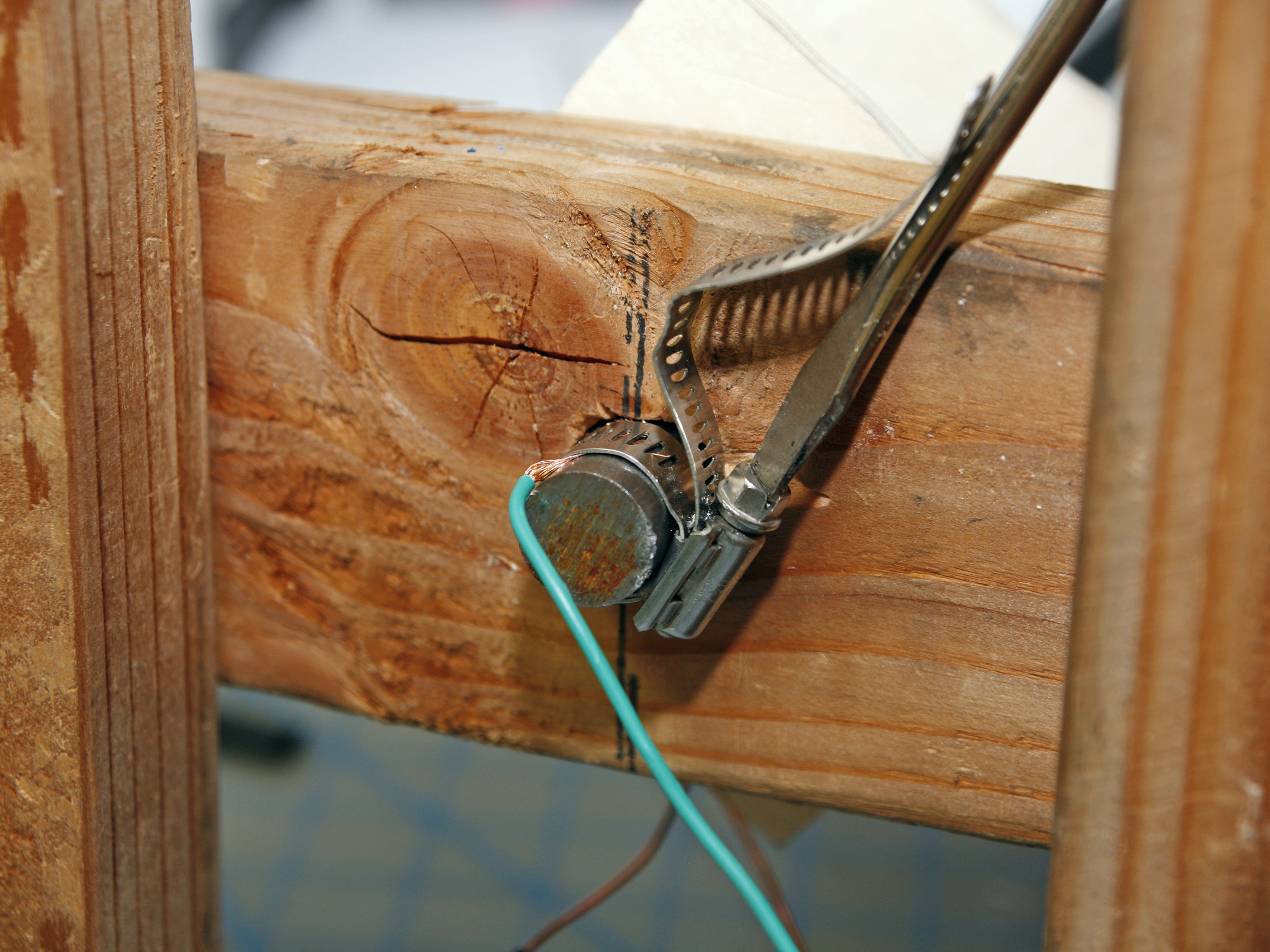

To make the ring levitate, switch the power strip on first, then immediately slip the ring over the rod using one hand (keep the other behind your back). This is easier with 2 people (and safer and more fun). Notice that the ring stops and hovers instead of falling. The ring is levitating! Then shut off the power immediately, or else the fuse will blow within a few seconds and need to be replaced.

For more fun, try shooting the ring upward. For safety’s sake in your first attempt, wrap the ring with 2 layers of electrical tape. This will weigh it down so it won’t shoot very high. Put the ring on the rod and let it slide down to the coil. Step back about 10', then turn on the power strip. The ring should shoot up enough to come off the rod. If you want it to go higher, remove some or all of the ring’s tape.

Faster and Higher!

This is a demonstration project. While its operation is impressive, you can shoot the ring higher and faster if you make a few changes. For all these enhancements, the most important precaution is to locate the coil and rod even farther away from the switch, yourself, and any observers. To do this, use a 50' extension cord in the build, or add it in between the power strip and the levitator plug. Any enhancements are for shooting only — not the levitating trick. No one should get close to the live rod.

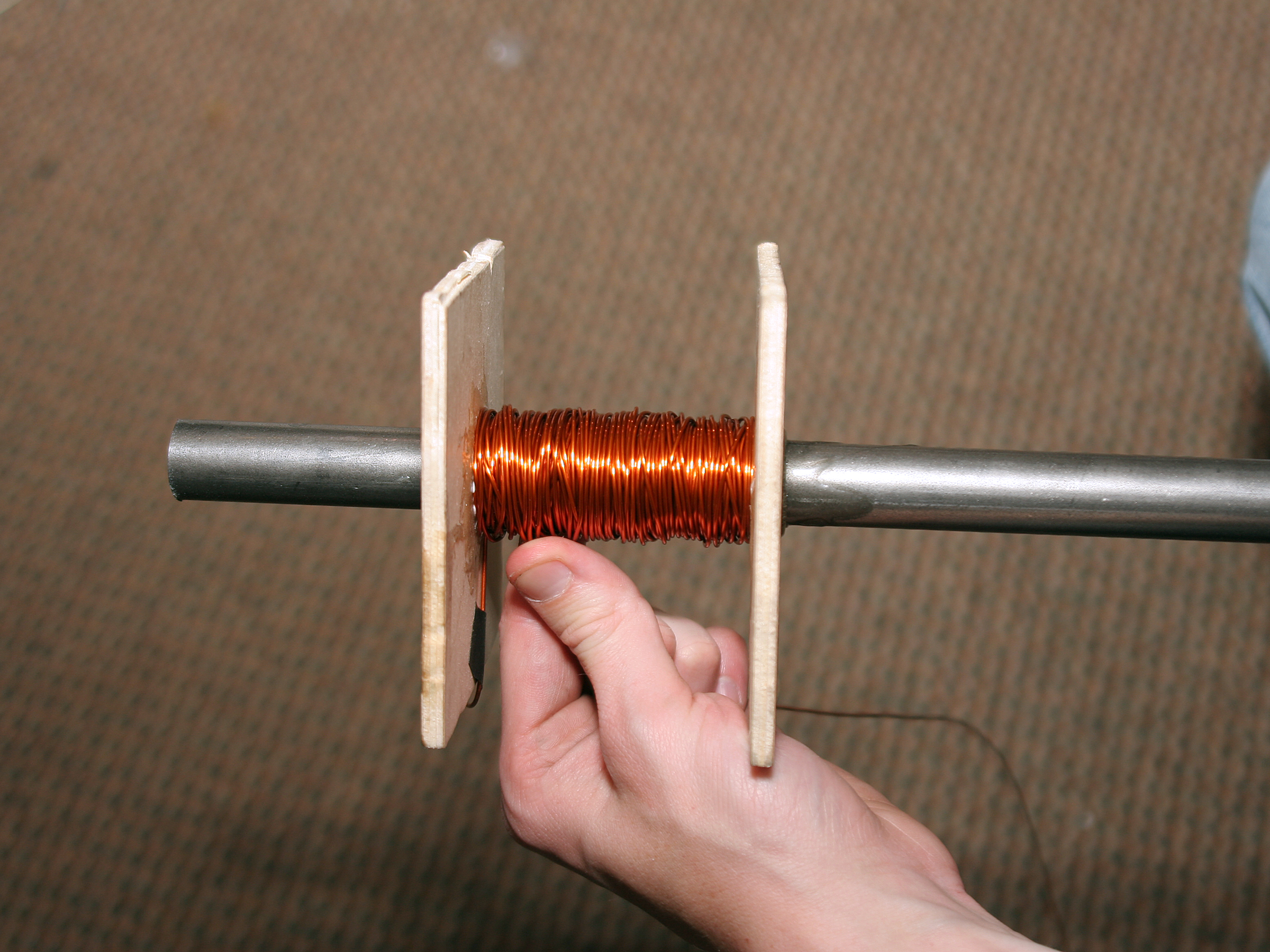

One improvement is to use a rod made from special purified iron instead of the cold-rolled steel rod. Second, you can try using heavier-walled aluminum for the ring, and experiment with different lengths. Third, you can make a larger coil with more turns.

With any such “enhanced levitator,” make sure you take the same precautions used by model rocket hobbyists. Following are some rules adapted from the National Association of Rocketry’s safety code (http://nar.org/NARmrsc.html).

- Use a countdown before launch, and make sure any guests are paying attention and are a safe distance away at the time of launch.

- Place the levitator on a table or platform, and aim the rod close to vertical (within 30°). Never point the rod at anyone!

- Test the levitator first outside in an open area that exceeds a 50' radius. Locate it at a safe distance from overhead power lines.

You may notice that the ring shoots up faster at times, with the least impressive performances generally occurring while you’re showing someone you want to impress. The difference in heights depends on the instantaneous AC voltage, which in a typical house can vary from below 110V up to 120V.

SAFETY WARNING: Do not try to shoot the ring to the moon by hooking the coil up to a voltage source higher than 120V AC. For example, do not try this project with 240V AC. Even if the magnet wire’s insulation holds up, you can start a fire or cause serious injury. Leave higher-voltage experimentation to the military or MythBusters!

This project first appeared in MAKE Volume 24, page 100.