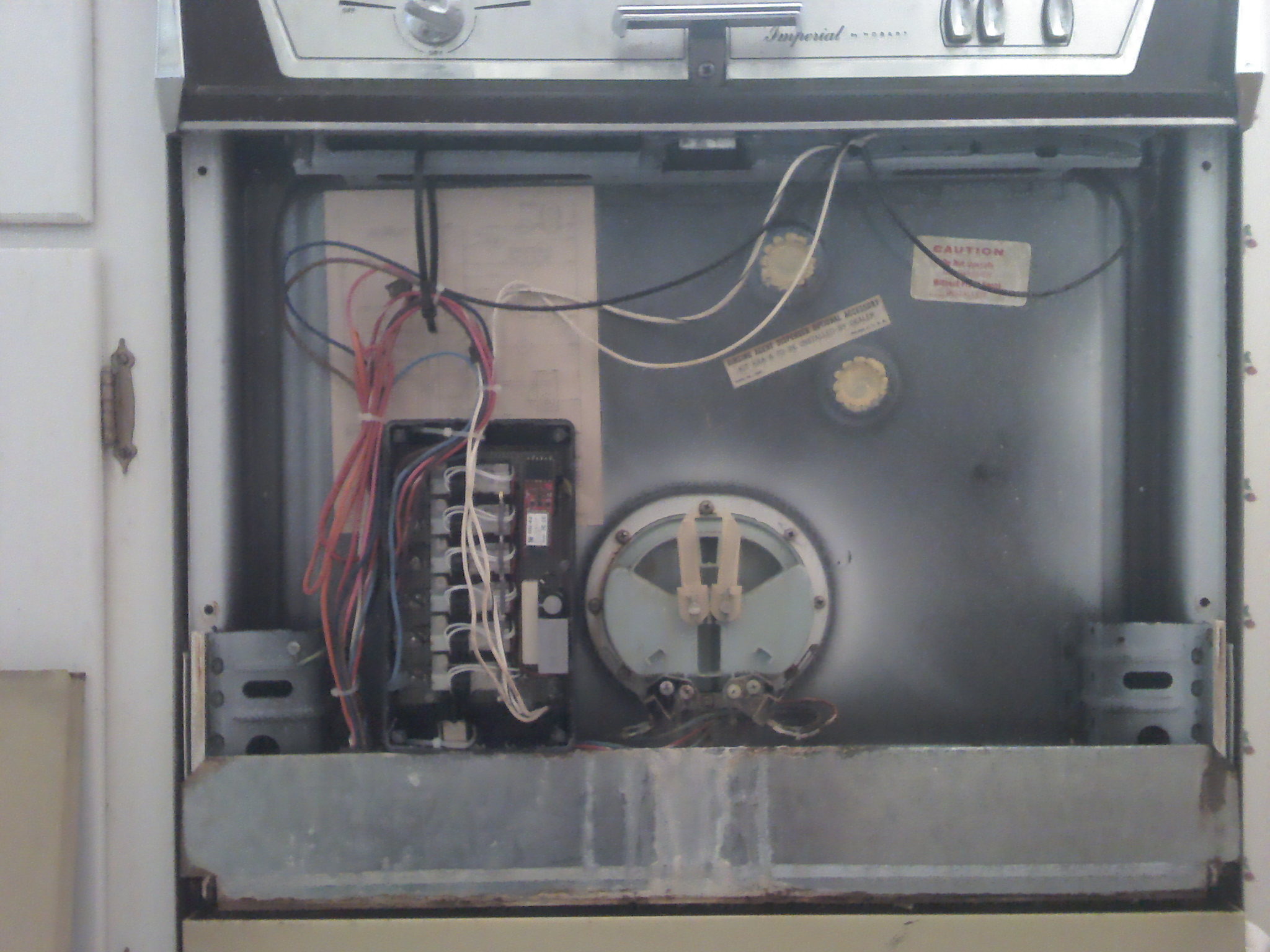

WARNING: The circuits shown herein do not provide isolation from the AC mains, and therefore any part of the circuit can be exposed to dangerous voltages relative to earth ground. Extreme care must be observed in testing or handling these circuits while connected to the powerline.

AM486 appliance modules are essentially relays that are rated for 120V/15A and thus they are well suited to the task at hand. These relays are of a bi-stable design, meaning that they require no holding current to remain either open or closed but additional circuitry is required to determine their current state.

For this project one relay was allocated to each of the functions in the dishwasher which are:

- pump motor

- water fill

- drain

- soap dispenser #1

- soap dispenser #2

- blower motor