A while ago I wanted to get a magnetic knife rack for a set of fancy chef’s knives I had received as a gift. This would keep them out of a counter-hogging knife block or, even worse, the kitchen drawer, and in a convenient, easy-to-reach place.

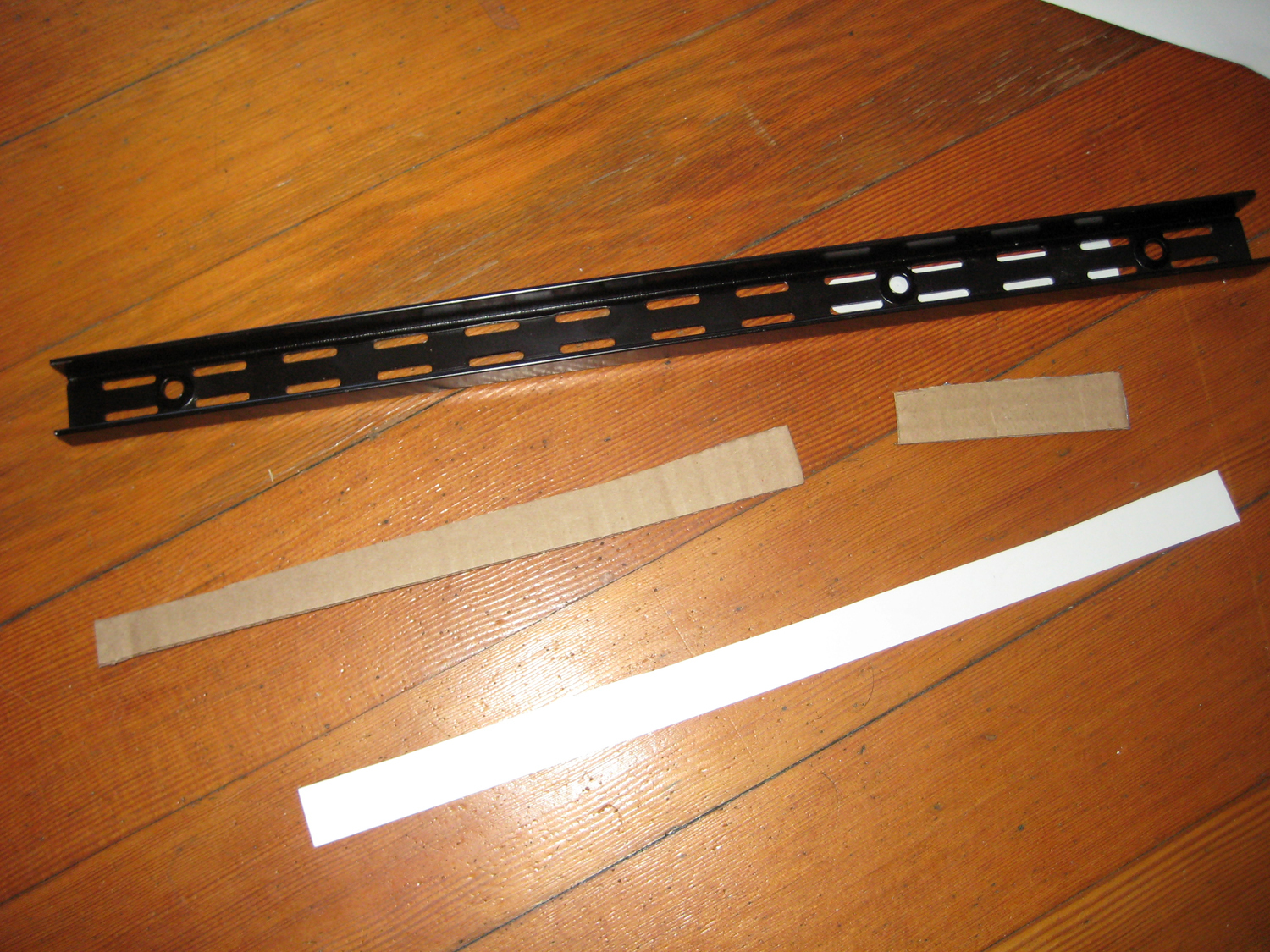

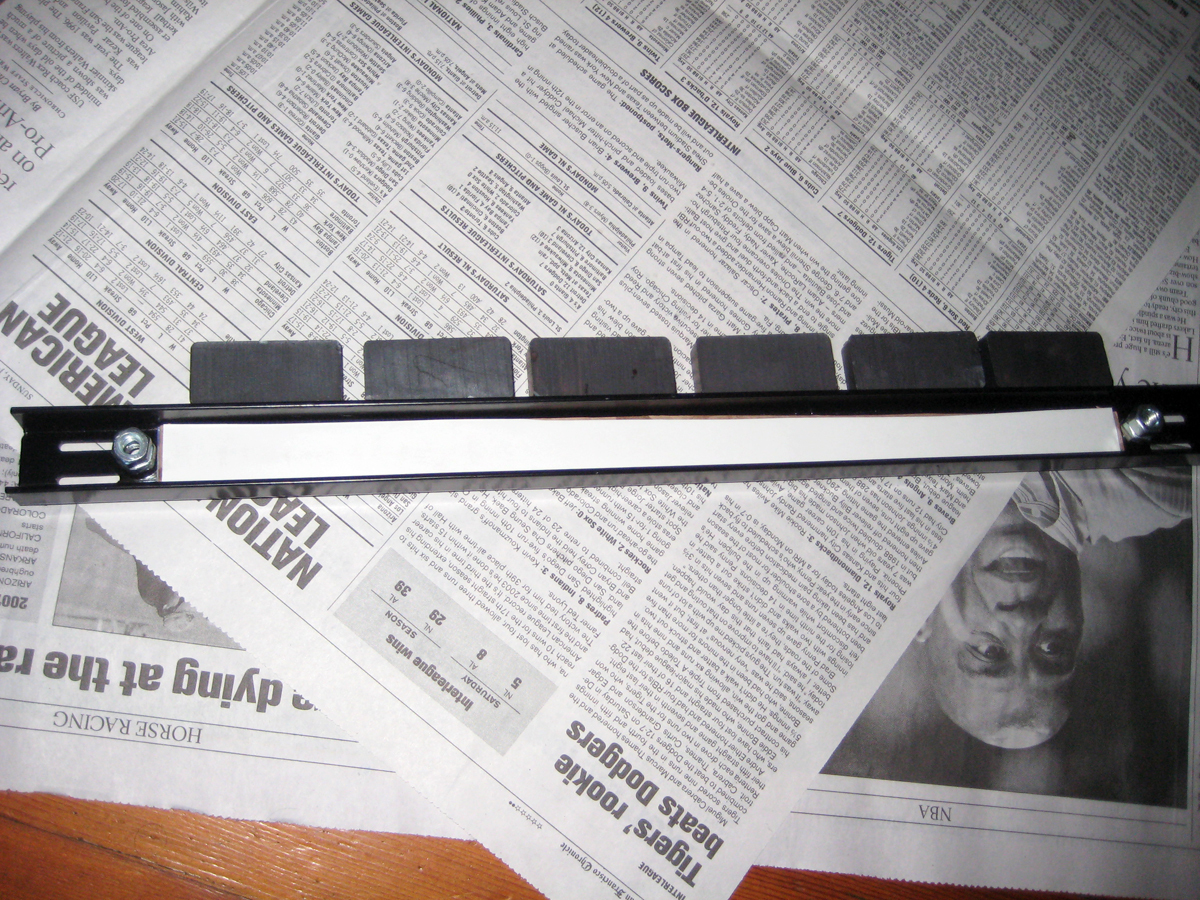

Dismayed with the price of a professional rack, I decided to build my own. Besides being cheaper, it’s moddable and customizable, since I can choose the length and the pattern on the front. I think it’s more stylish than the simple magnetic racks you can buy at the store, and the softer surface saves wear

and tear on your knives.