Conclusion

Firing the Night Lighter 36 Potato cannon

- Remove the end plug.

- Center and push a potato into the cannon, keeping your hand clear of the edge. You may want to wear a leather glove. The muzzle’s sharp edge will cut the potato into a plug that should fit snugly on all sides. Any gaps will reduce performance.

- Use the stick to push the potato plug 30 inches down into the barrel.

- Direct a stream of aerosol into the firing chamber. Unscented deodorant works well, but check the label to make sure your choice contains hydrocarbons such as alcohol, propane, butane, or isobutane. Start out with a one- to two-second burst, and determine the optimal amount by trial and error.

- Immediately replace the end plug and screw it in securely.

- Turn the stun gun on, and double-check that the firing area is clear.

- Press the stun gun’s ignition button. Enjoy your work. For a tracer, stick a glowstick into the spud.

If you have a misfire, and the projectile is not ejected, carefully remove the end cap, and ventilate the combustion chamber thoroughly.

Maintenance

Aerosol chemicals can gum up the inside of the cannon. Every few shots, clean it out with a rag and cleaner. The residue can also make the end plug hard to unscrew. If necessary, use pliers.

Safety and legality

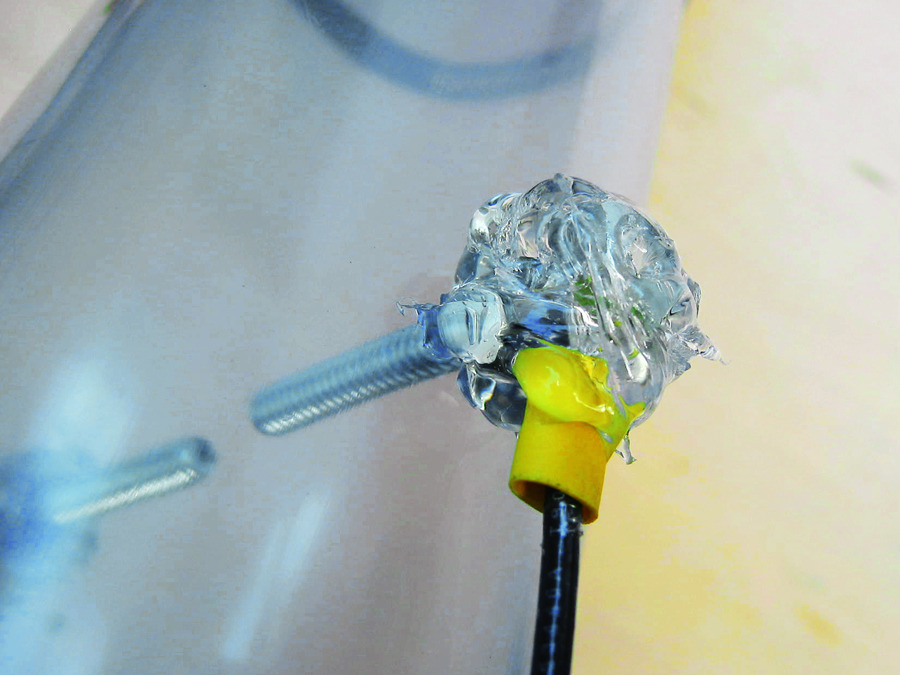

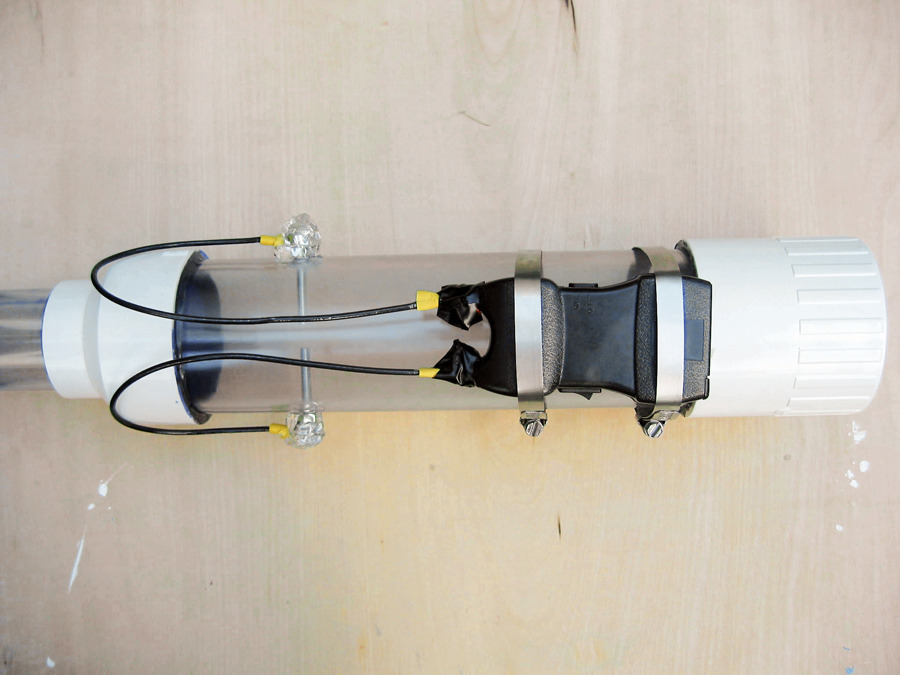

During construction, don’t take shortcuts or substitute inferior materials. The vapors from PVC cement are flammable, so allow all joints to dry fully before exposing the gun to ignition sources.

When using the potato cannon, exercise extreme caution. Wear eye protection, and check the area in front of you before firing. Never look down the gun's barrel, or point it at anything you don’t want to hit. Excess fluid stays in the chamber and evaporates slowly, so you should always treat the gun as if it can fire. Check frequently for signs of wear, and never operate a damaged gun. Avoid contact with (or proximity to) the ignition path. Stun guns hurt.

PVC is more brittle in cold weather, so don’t use the cannon in temperatures below 60ºF.

Neither the author nor this magazine assumes liability for your spud gun or your actions.

Potato cannons may not be legal in your area (even if it is legal to tote a 12-gauge down Main Street). Check with local law enforcement regarding the rules in your area, and obey them. Also, check the laws regarding stun gun usage.

Editor's note: Author William Gurstelle uses PVC for his Night Lighter 36 and other designs, but some spud gunners believe this is unsafe, since PVC can shatter and is not recommended for piping compressed gases. They advise using materials made out of ABS (with ABS cement), which is more flexible than PVC, but not available in transparent.

Alternatively, you can use Schedule 80 transparent PVC, which is thicker and stronger than Schedule 40, but more expensive.

This project first appeared in MAKE Volume 03, page 108.