Torch lighters are handy, cheap, and easy to find. They come in a wide variety of shapes and styles, so there’s room for customizing to your personal taste.

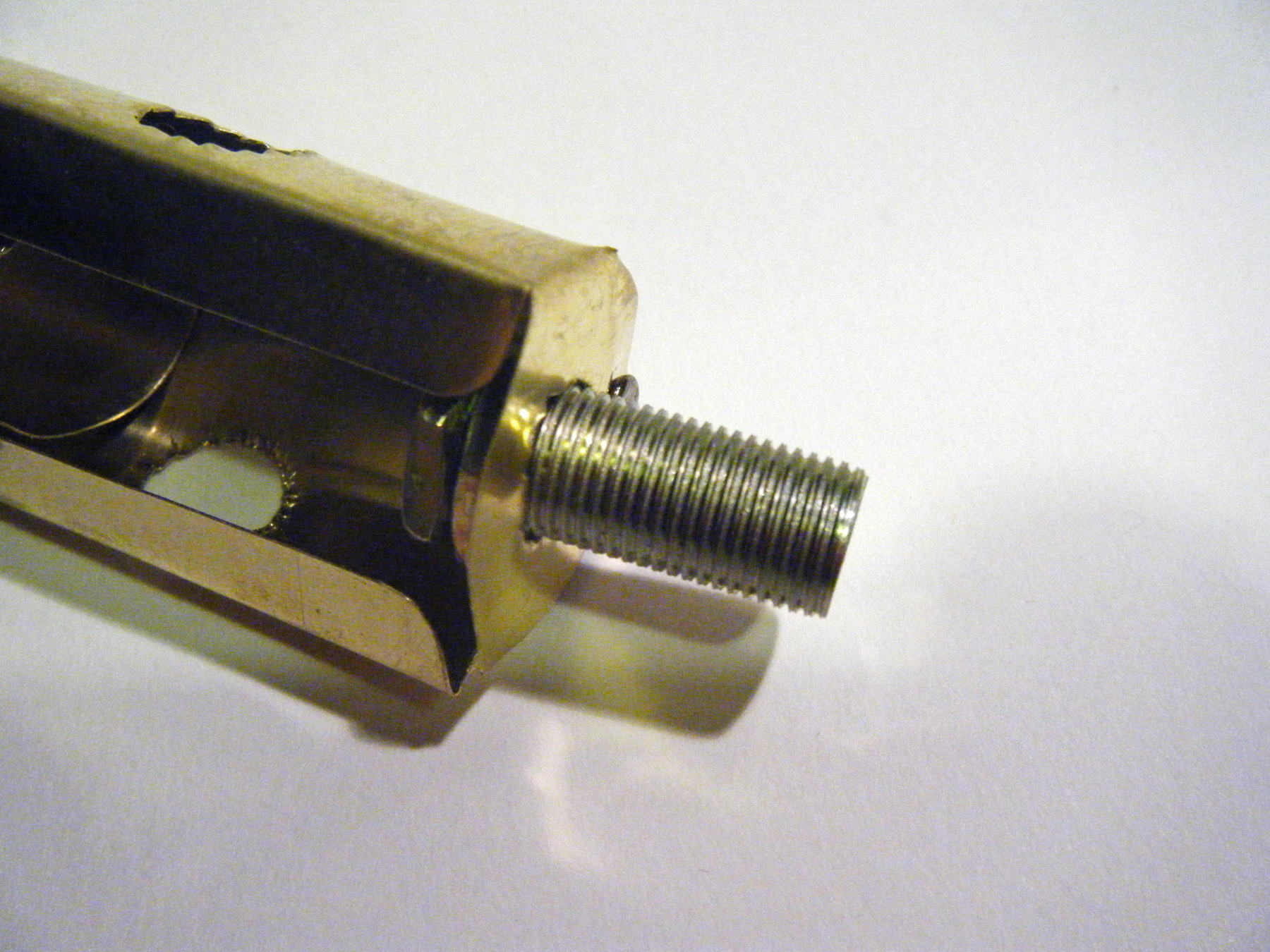

I normally modify mine with antique parts, but here I chose parts that you can get in most hardware and home stores. The finished raygun works well as a prop; simply pull the “trigger,” and an inch or so of fire shoots out the barrel!

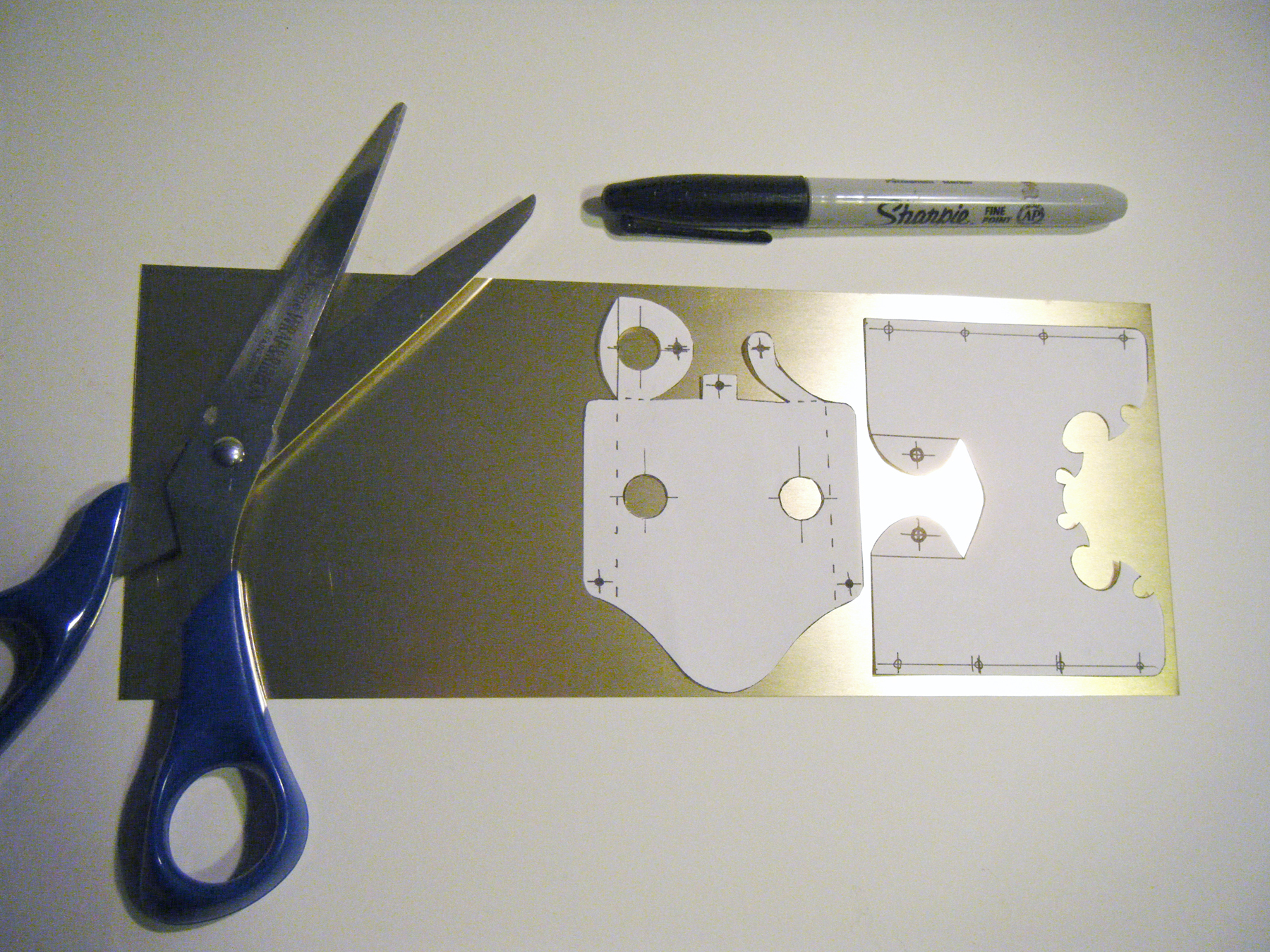

This project uses a $10 Dodo brand lighter. If you use a different lighter, you may need to change the size of the pattern to accommodate it. You need to use a lighter that, when installed into the barrel of the raygun, will shoot forward.

Some point in other directions — obviously, avoid these, unless you specifically want a booby-trapped gun!

You might try a different ornate coat hook for a different-looking handle. The handle can also be mounted forward or backward.

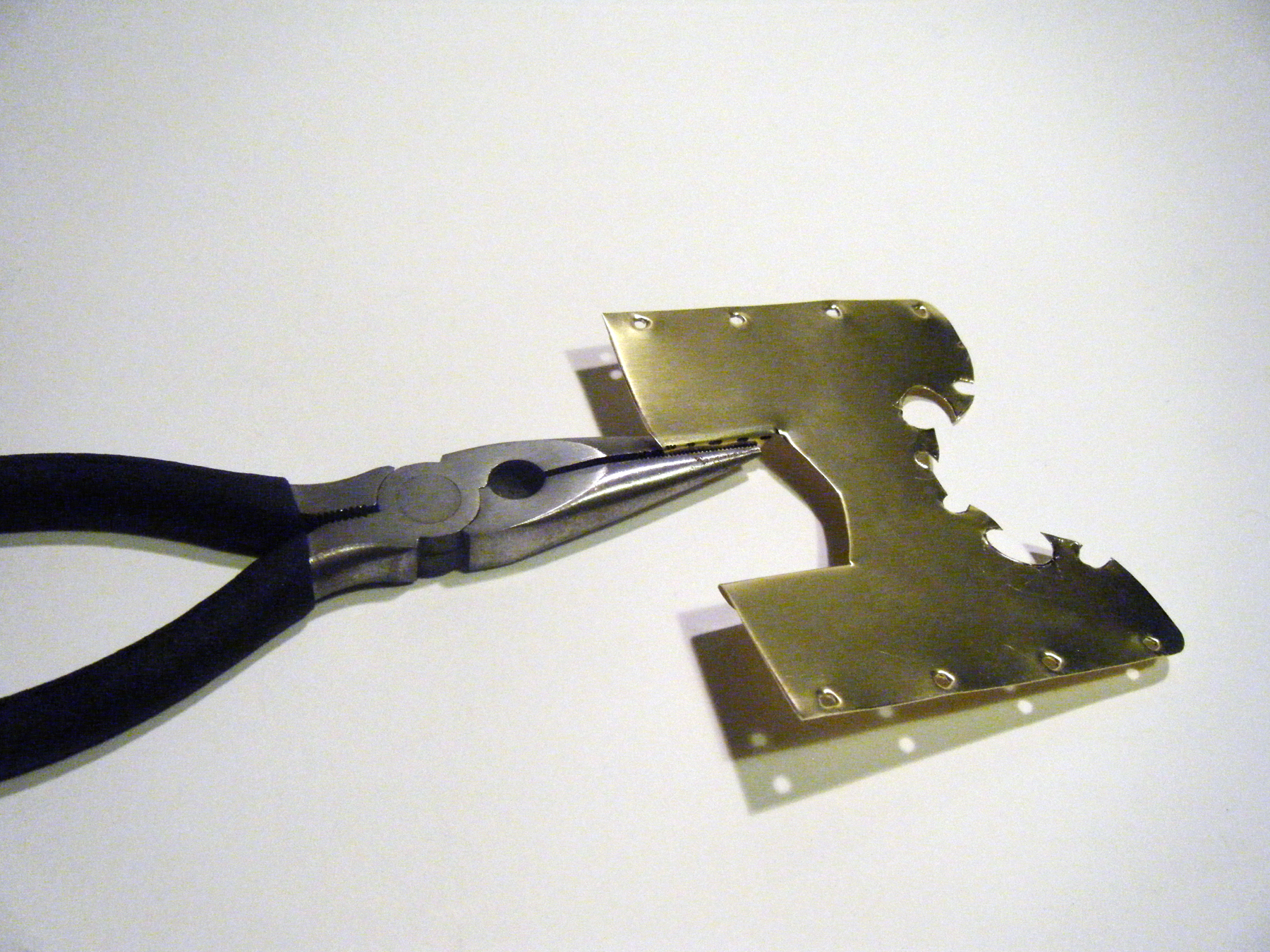

The lamp parts are easy to customize — you can change the look just by using different finials and other decorative elements — and the design on the front of the barrel can be almost any shape you want.

This project is fairly easy to do, takes a few hours, and costs about $30–$40 in parts (less if you have some stuff already on hand).