I have long been enamored of catapults. Invented around 400 B.C., they were used until nearly A.D. 1300. So for 1,700 years, catapults were arguably the largest, most expensive, and most powerful machines on the planet.

Today, people build catapults for fun: Scout troops, historical reenactors, fathers and daughters, beer-stoked college students. Having built more than a few, I’ve found it’s not nearly as easy as it might appear.

First, for any projectile larger than a golf ball, catapults have to be big, and building big things can be a challenge in terms of cost and tools.

Second, there are incredible stresses at work within the moving parts of a catapult. Unless good designs and materials are used, wooden support beams break, rods bend, and joints collapse in ways unexpected and sometimes even dangerous.

Third, they are big. Did I already say that? Well, it bears repeating because once you build the thing, you need space to use and store it. I’ve learned that finding a place to store a catapult is a huge pain — very few people are willing to park their cars in the driveway to free up garage space for their catapults, no matter how much they love to hurl.

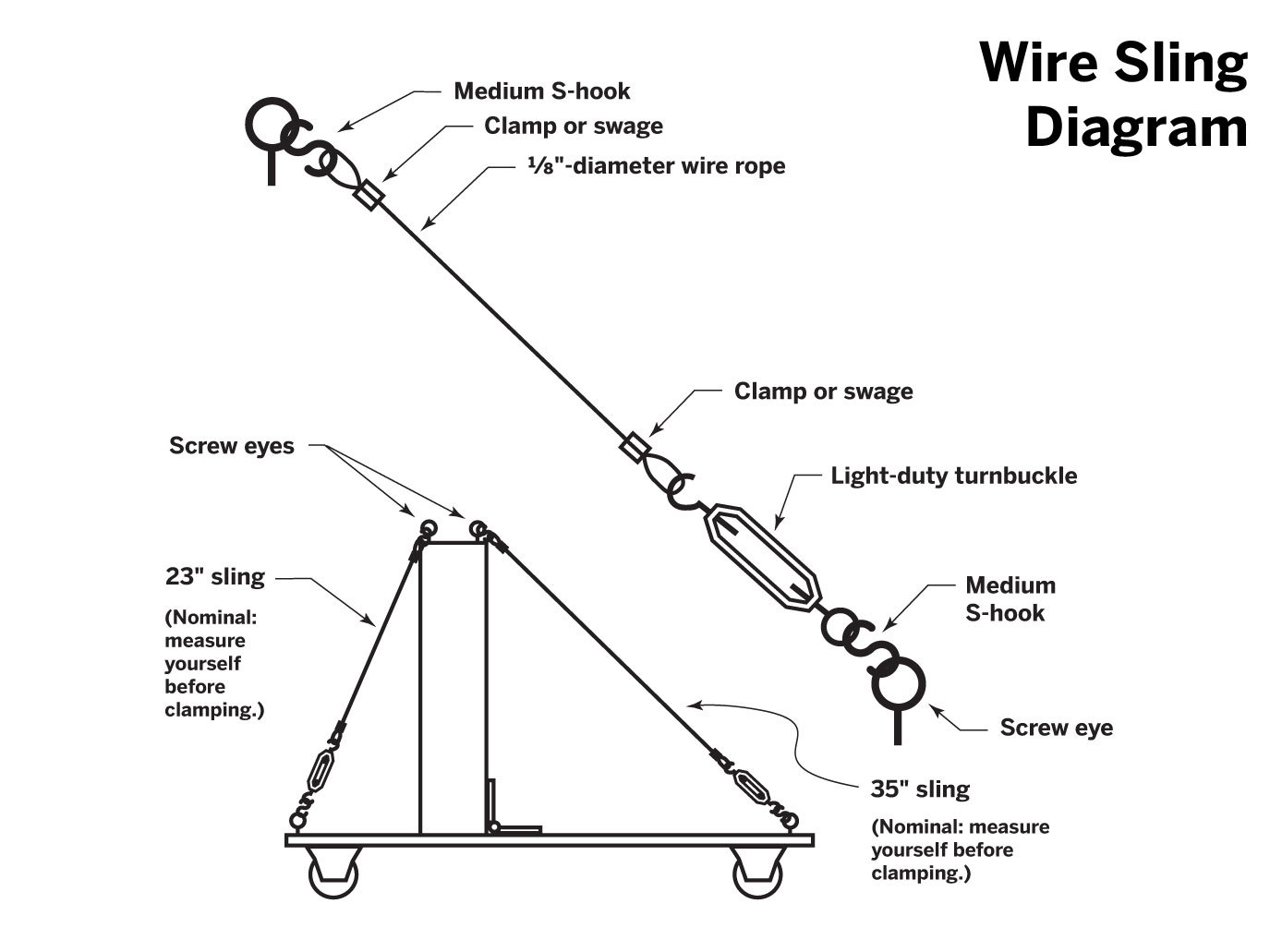

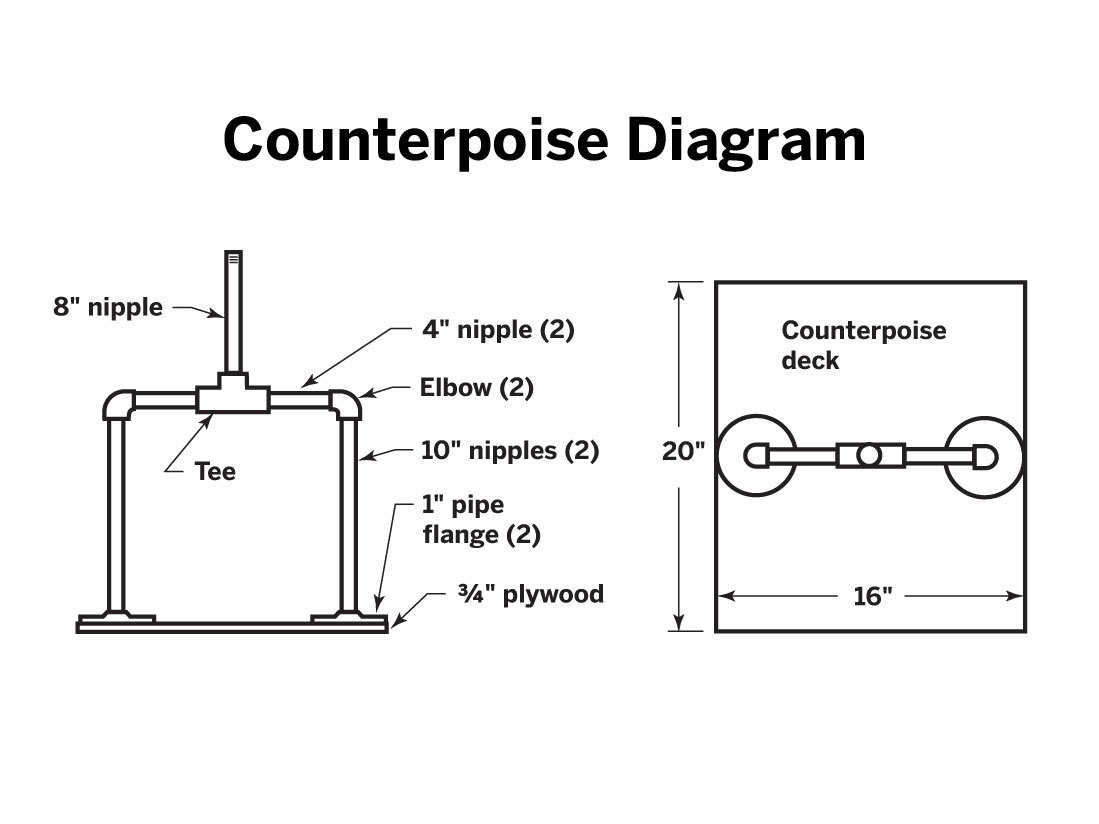

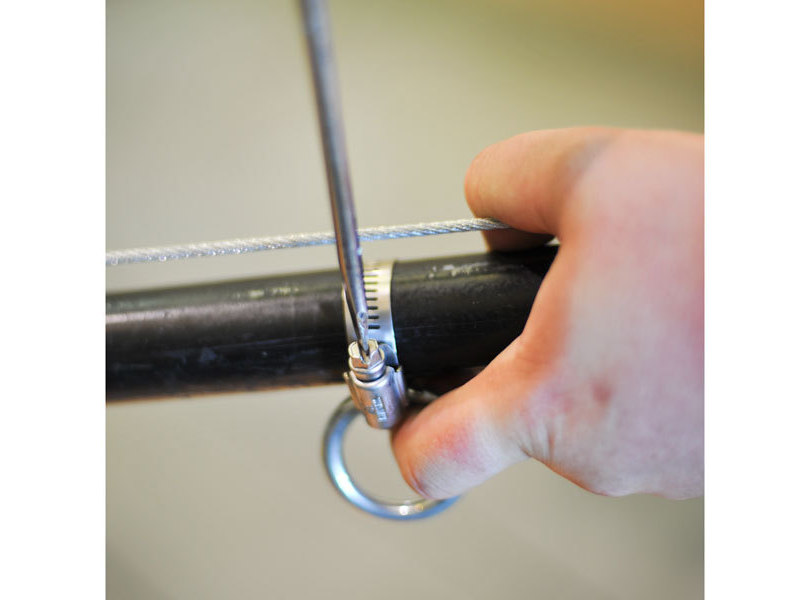

This gravity-powered catapult is fairly simple to build using a minimum number of tools. Built with modern materials instead of medieval timbers, it’s small and light enough for one person to push around. Best of all, it rolls around on wheels and folds flat (sort of) so it can be stored in a fraction of the space needed for traditional catapults.

While the Folding Catapult is customizable, don’t get carried away — 120lbs is about the maximum counterweight that can be used.