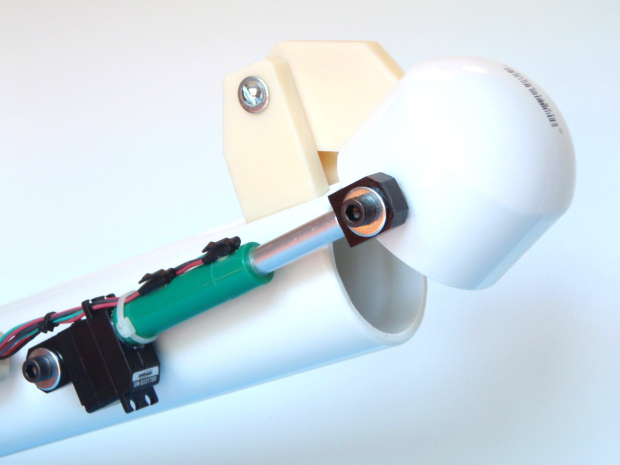

I needed a small linear actuator (a mechanism for creating motion in a straight line) for a project and was finding only oversized or cost-prohibitive solutions. Industrial automation actuators have plenty of muscle but rarely come in small packages. Hobby linear actuators come with a smaller footprint but can be costly. I’ve often wondered about the load capacity of the screw and nut contained in a standard lip balm tube, so I collected all the lip balm tubes I could find and started testing.

One stood out over all the others and could exert over 10 pounds of thrust with a 1.25″ stroke: the mighty Blistex tube. No other lip balm screw-and-nut assembly comes close to carrying the same load as a Blistex tube. Add a magnet to the shaft and a couple of reed switches to the case, and you’ve got an actuator with limit switches at each end!

Tools

- Drill and drill bits: 3/8″ Forstner, 3/8″ brad point, 3/16″

- Utility knife

- Tubing cutter or hacksaw

- File or sandpaper

- Screwdriver, flat-blade

Materials

- Clevis mounts, rear and front — Make these from ABS plastic, wood, or any material you’re comfortable working with. See dimensions in Step 7.

- Hobby servo, full rotation — SparkFun Electronics #ROB-10189, sparkfun.com

- Blistex lip balm tube — The actuator’s drive screw, body tube, drive nut, and cap are all made from it.

- Proximity sensors, magnetic, NPN, 3-pin (2) — Jameco Electronics #513244, jameco.com

- Magnet, 1/8″ square — SparkFun #COM-08644

- Aluminum tube, 3/8″ OD × 3″ — McMaster-Carr #9056K643, mcmaster.com. The shaft can be any nonmagnetic 3/8″ OD tube of it least 1/4″ ID — even plastic.

- Threaded insert, #8-32 — McMaster #92105A660

- Threaded shaft, #8-32 × 3/4″ — Cut this from any #8-32 bolt.

- Cable ties, small

- Plastic epoxy — J-B Weld works well.

Downloads

MAKE Volume 34: Join the robot uprising! As MAKE's Volume 34 makes clear, there’s never been a better time to delve into robotics, whether you’re a tinkerer or a more serious explorer. With the powerful tools and expertise now available, the next great leap in robot evolution is just as likely to come from your garage as a research lab. The current issue of MAKE will get you started. Explore robot prototyping systems, ride along with the inventors of the OpenROV submersible, and learn how you can 3D-print your own cutting-edge humanoid robot for half the price. Plus, build a coffee-can Arduino robot, a lip balm linear actuator, a smartphone servo controller, and much more

On newsstands now, by subscription, or available in the Maker Shed