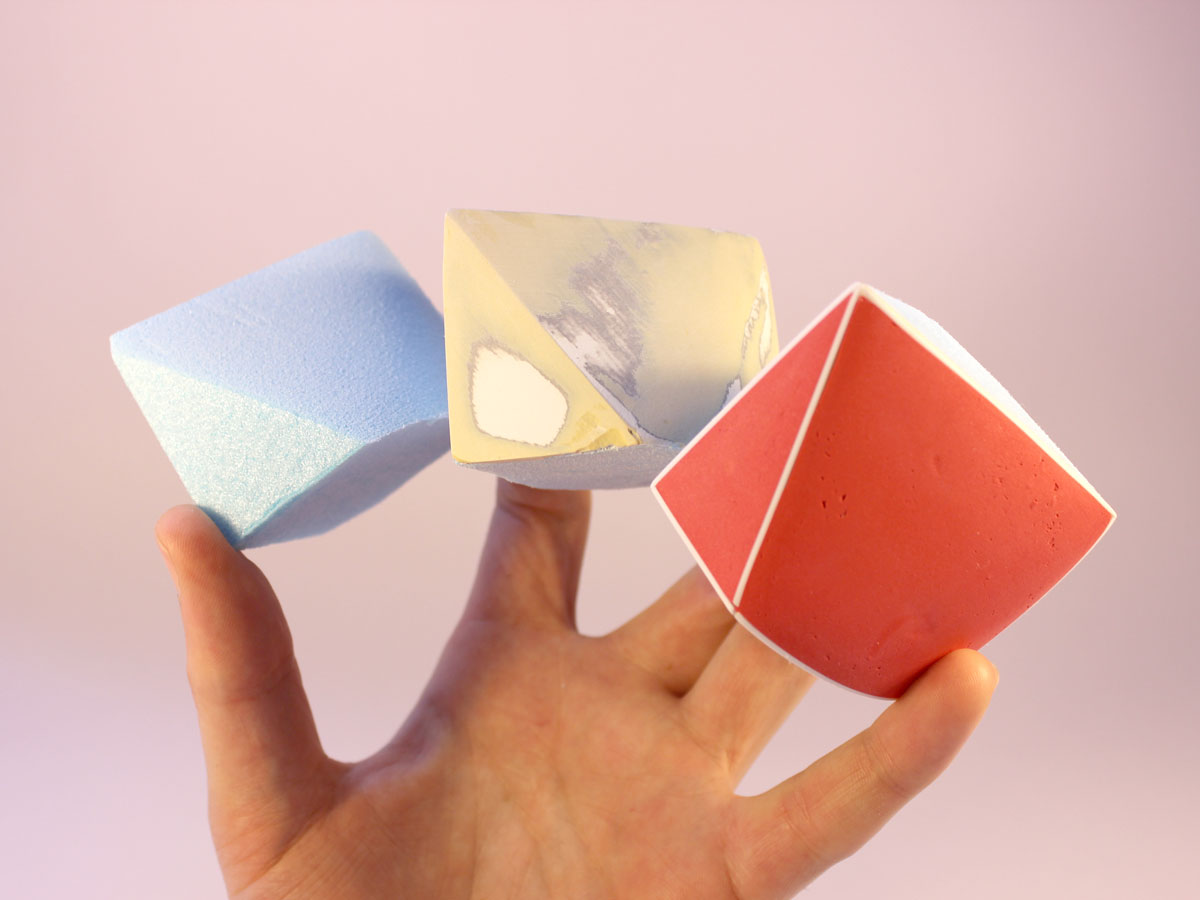

The modeling technique I used in my Ergo Mouse project has 3 main steps: sculpting, surfacing, and what is called Sugru skinning. But you can apply this process to any creative process requiring models to explore interactions and aesthetics, quickly and at low cost.

What is Styrofoam? Sometimes referred to as simply ‘Blue Foam’ or ‘Insulation Foam’, Styrofoam is extruded polystyrene – and is far stronger than the white polystyrene you find in coffee cups and packaging pellets. It can be worked by hand into complex shapes quickly and because it has a fine ‘grain’ it is ideal for modeling and is used widely in design industries for exploring aesthetic and ergonomic considerations and also in architectural practices and in sets in film and theatre. One thing to note is that it is dissolved by various solvents found in superglues, chemical fillers and spray-paints – which is why it is advisable to coat your sculpted form in a water-based barrier such as Decorators’ Filler (Spackle or PolyFilla). However, you can use glue-gun to stick chunks together.

There are many ways to work with Styrofoam, for example some people use hot-wire cutters and CNC routers, but the following steps will offer some tips that are both safe and affordable and give good results for small-medium sized models.