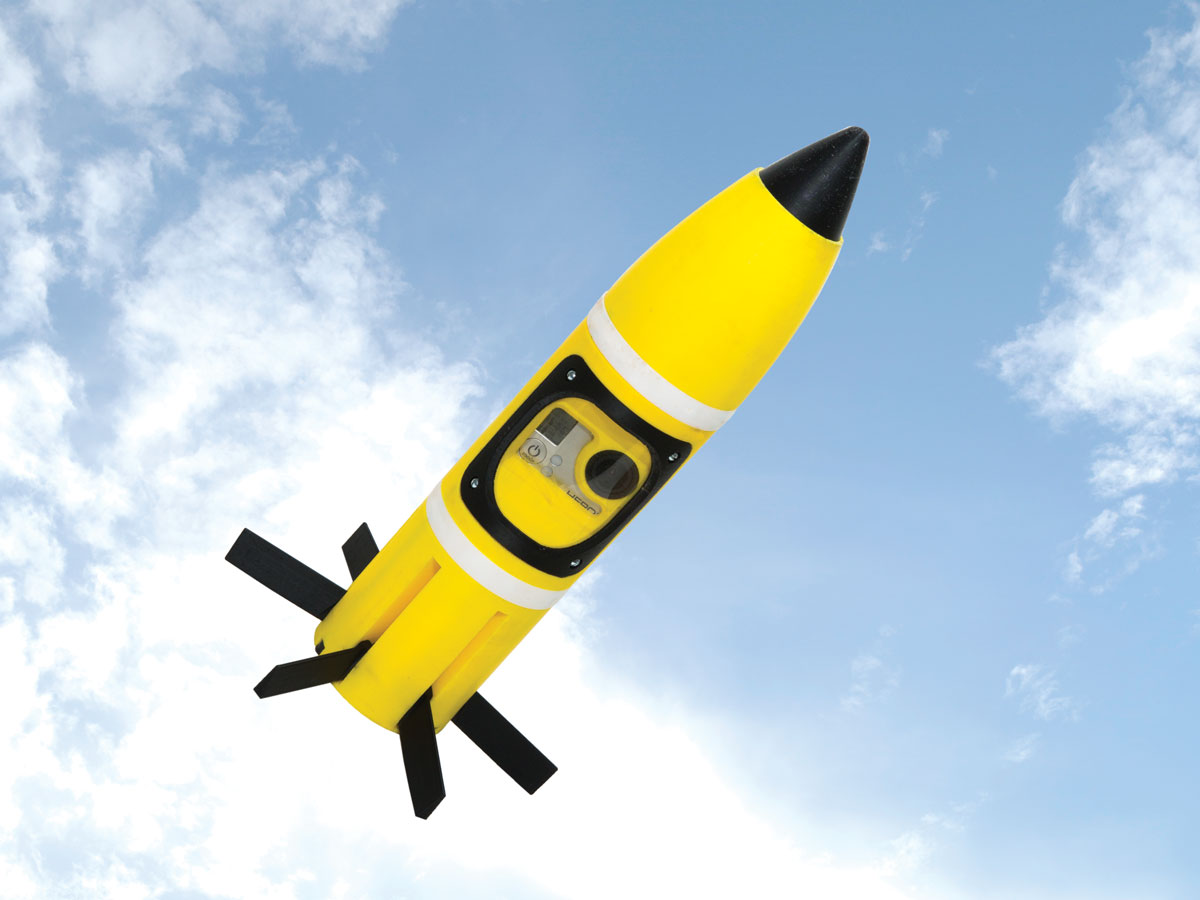

The original Cannon Cam shell was one of the first custom 3D projects I made when I started working at Make Labs. Due to the design constraints of the Thing-O-Matic 3D printer, the idea was doomed from the start, but I printed it out anyway. (It looked cool and I was excited about 3D printing.) It sat on my workbench for 3 years, until my editor noticed it during a brainstorm session for new 3D-printed projects. I told him it would probably wobble in flight and shatter on the first crash landing. Intrigued by the concept, he asked if I could design a new one that would fly stable and survive a crash. Of course I said yes — I can’t pass up a design challenge. The result was this new GoPro Cannon Cam, and video from the unique perspective of a human cannonball.

Originally, to give it stable, roll-free flight I added an electromechanical gyro stabilization system in addition to 6 spring-loaded retractable fins. To help it survive landings I designed a shock-absorbing nosecone and a non-electronic time delay parachute deployment system, triggered by the inertia the projectile experiences when fired from the cannon. After spending days researching World War II torpedoes, warhead fuses with clockwork time delays used by the Nazis, and gyro cars from the 1900s, I developed a projectile with several “modules” that each had a different function.

A nose cone module featured a spring-loaded shock-absorbing tip to protect the rocket on impact. But the impact would be lessened by a parachute module; a fan would rotate a series of lugs and when they lined up, the rear section would break away and drag a parachute into deployment. Meanwhile, a camera module with a built-in window held the camera in place without disrupting the aerodynamics. The gyro module had a small motor, mounted on a one-axis gimbal, that powered a steel washer flywheel. The final section was the retractable fin module, which was rigged to break away.

To incorporate all those components required a “rocket” almost 2 feet long and weighing around 6 pounds. (I have a tendency to over-engineer things.) So I took a step back. I abandoned the gyro and parachute systems in favor of a small, lightweight projectile with the shock-absorbing nose cone, camera, and retractable fins. If the projectile was light but strong, I reasoned, it would survive landings at terminal velocity. After a quick destructive test of a 3D-printed part, I incorporated threaded rods running the length of the body to hold the parts in compression and help it resist delamination during violent impacts. All that was left to do was print it out and test-fire it.