This circuit is a modified version of a charge controller circuit that was designed by Mike Davis (http://www.mdpub.com/555Controller/index…).

In the original circuit, a 555 timer IC was used to disconnect a battery from the solar panel when its voltage gets too high (to prevent it from over charging). In my design, the control circuit connects the battery to an inverter and an output circuit when the battery is fully charged.

Here is a brief description of how the circuit works. A 5V voltage regulator powers the 555 timer IC and sets its internal reference voltages. A pair of potentiometers (variable resistors) are set up as voltage dividers that provide a signal to the timer IC that is proportional to the battery’s voltage.

These signals determine the operating range of the system. As the battery’s voltage rises and falls, so does the output signals of the potentiometers. When the signal at pin 6 rises above 3.3V, the output of the IC goes LOW and activates the relay through a series of transistors.

When the signal at pin 2 falls below 1.6V, the output of the IC goes HIGH, which deactivates the relay. By setting the positions of the potentiometers, you determine at what voltages the battery must be to activate and deactivate the output.

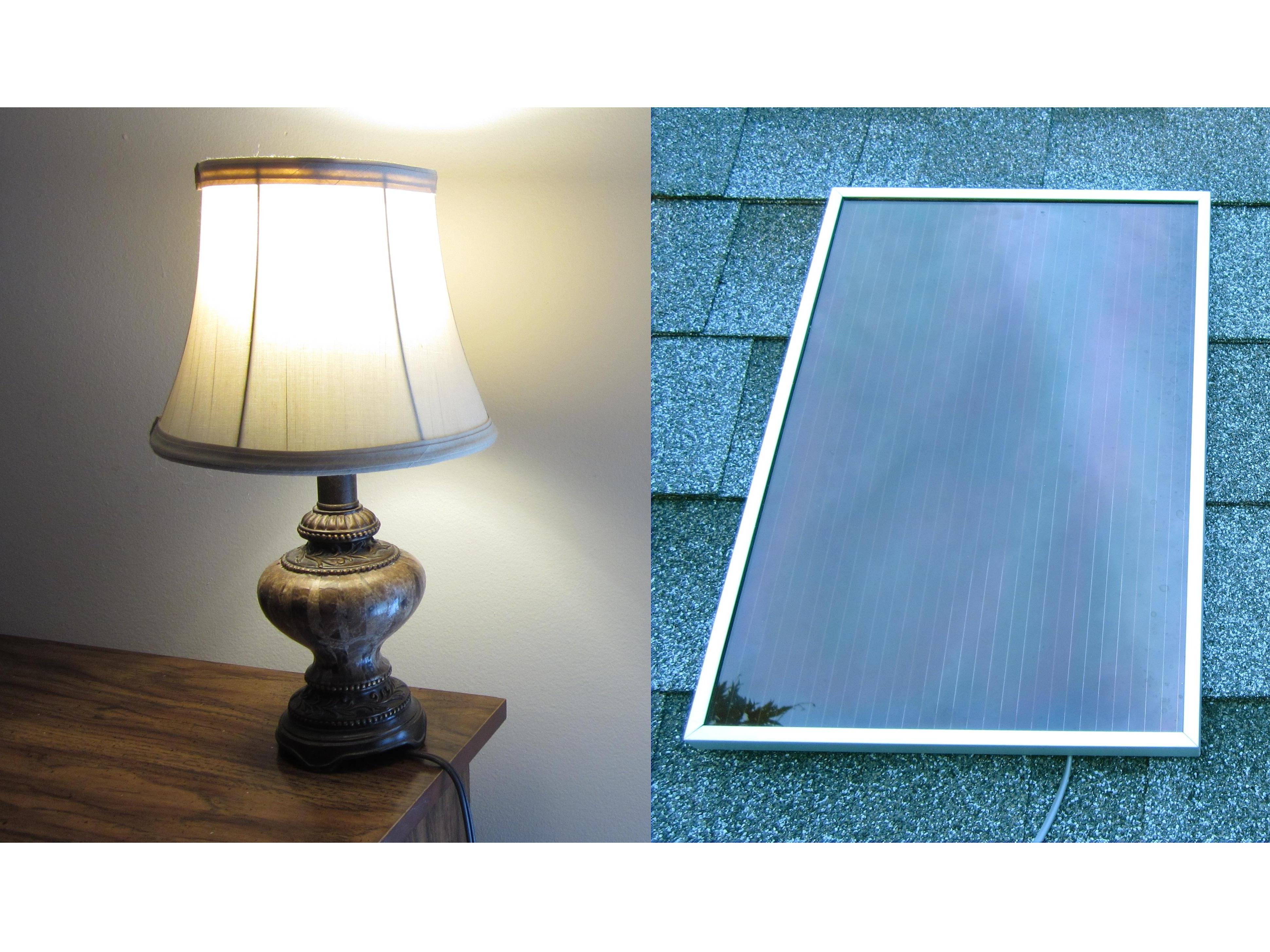

Alternate Design with Charge Controller A charge controller usually isn’t required for this setup. If the output of your solar panel is small relative to the storage capacity of your battery and you are powering a device that is frequently turned on, then you generally don’t need to be worried about over charging the battery.

However, if you wish to use a charge controller, you may attach one between the solar panel and the control circuit. I have also provided an alternate circuit design that includes a charge controller built into the control circuit.