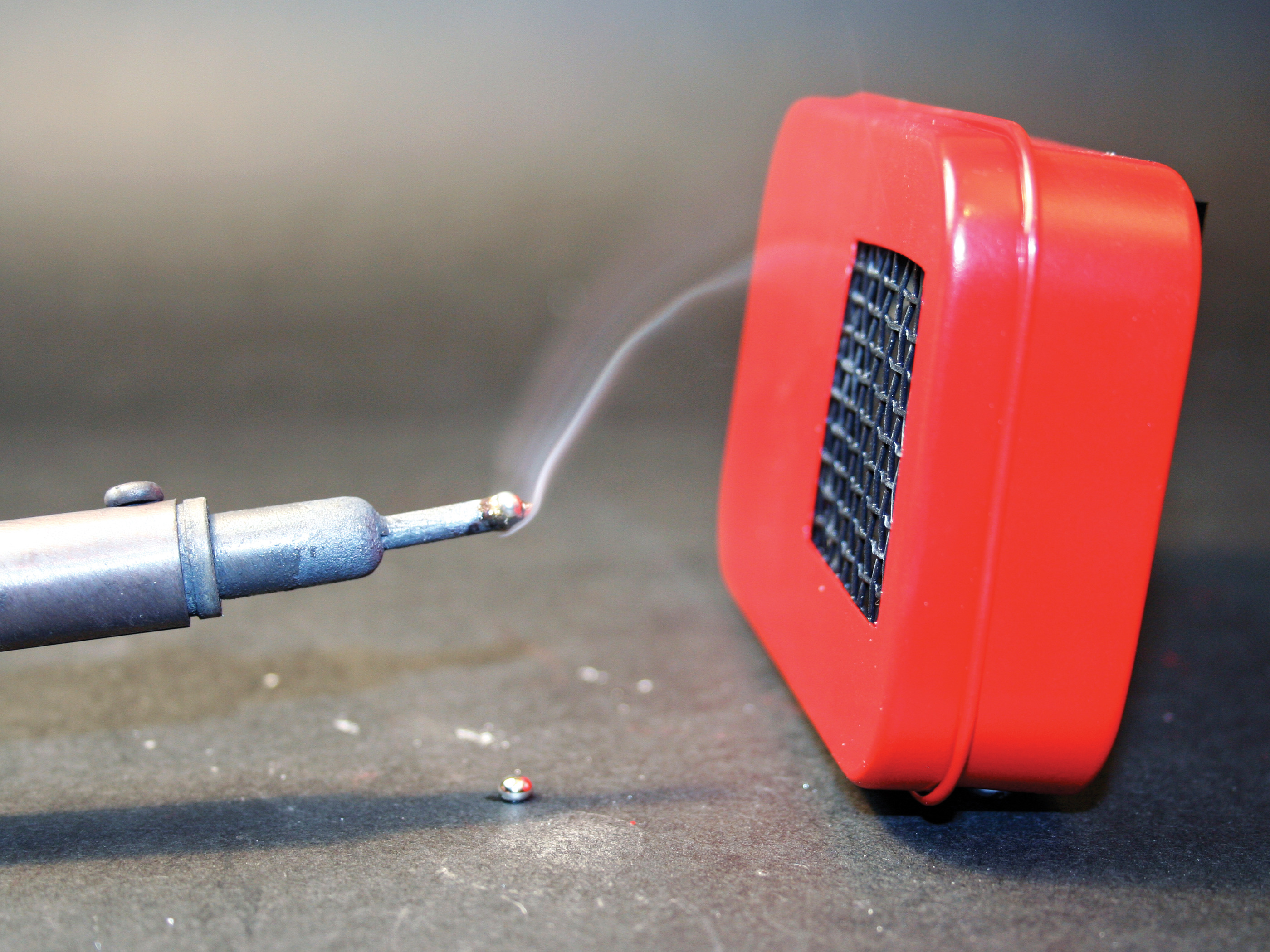

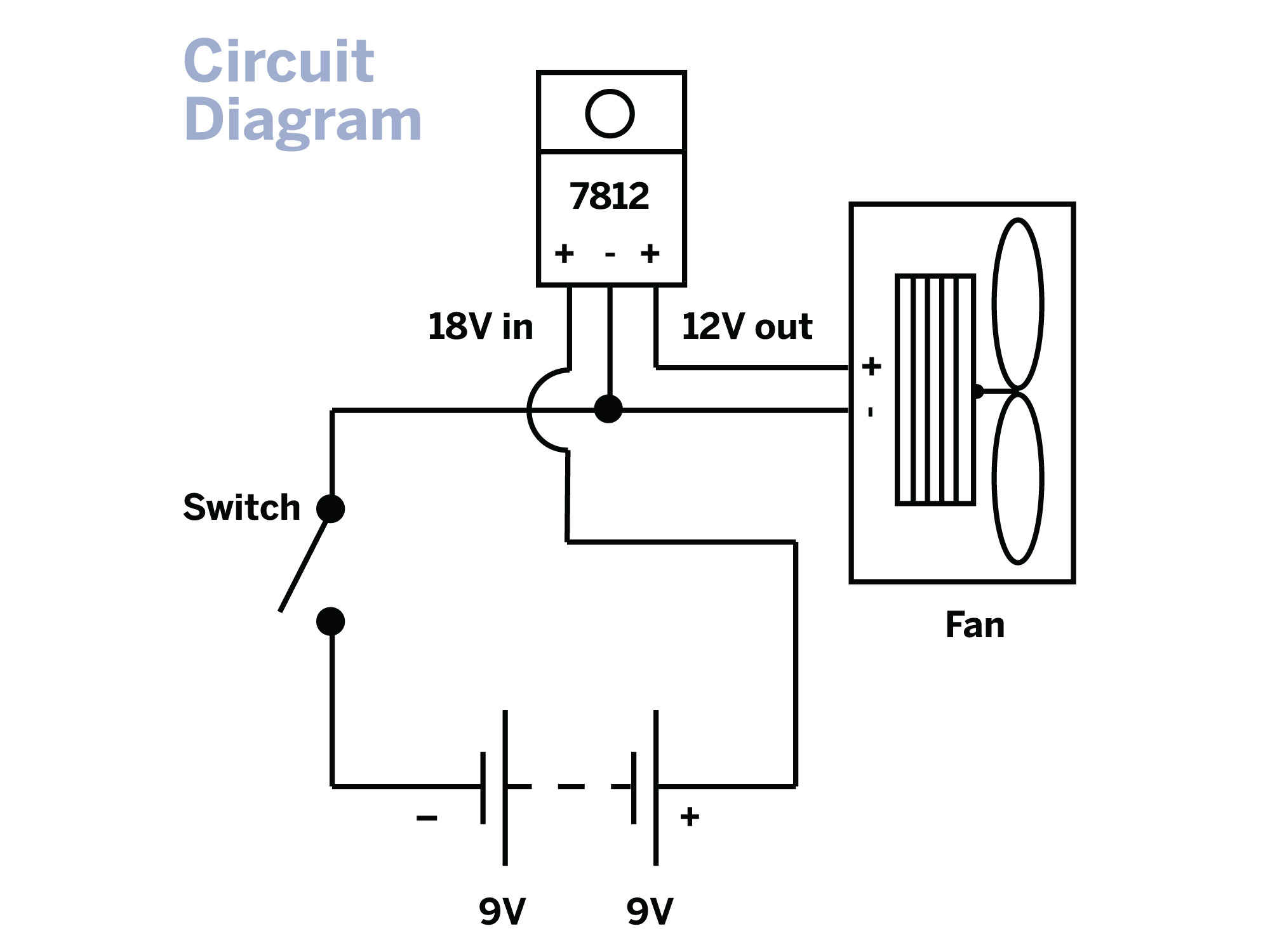

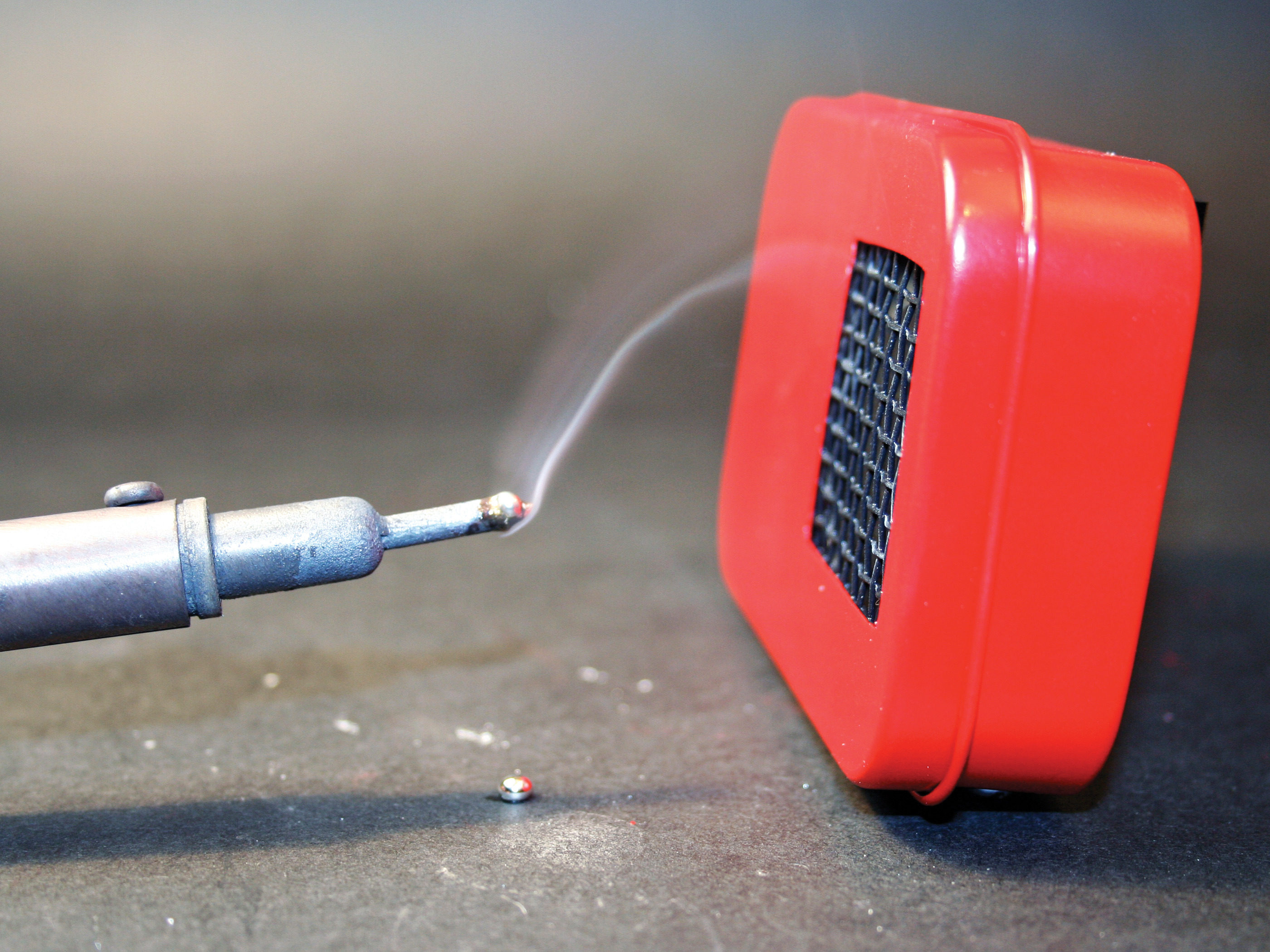

A fume extractor uses an activated carbon filter and fan to remove the smoke, and noxious fumes, created from soldering. The average price of a small hobby version is about $100, but this one made from the ubiquitous candy tin will run you more like $10. This mini fume extractor won’t be as effective as a larger one, but it’s definitely better than nothing, and extremely portable. Remember, always work in a well-ventilated area.