When Uplift Aeronautics founder Mark Jacobson envisioned using a fleet of drones to drop food and medical supplies on war-torn regions, he needed a device to make that happen. The answer was to modify fixed-wing foam UAVs, and the result was five different designs, including the Waliid, pictured here.

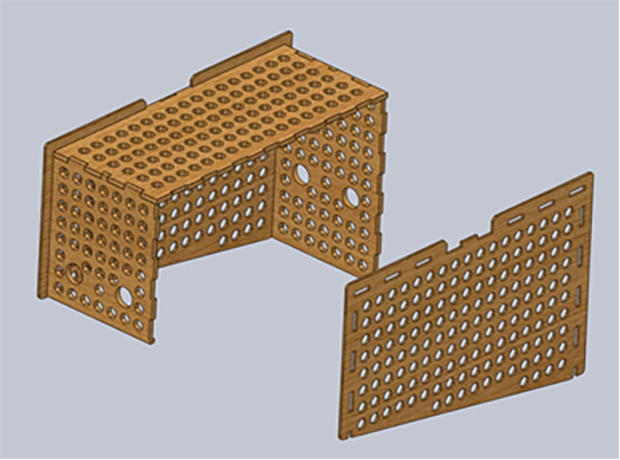

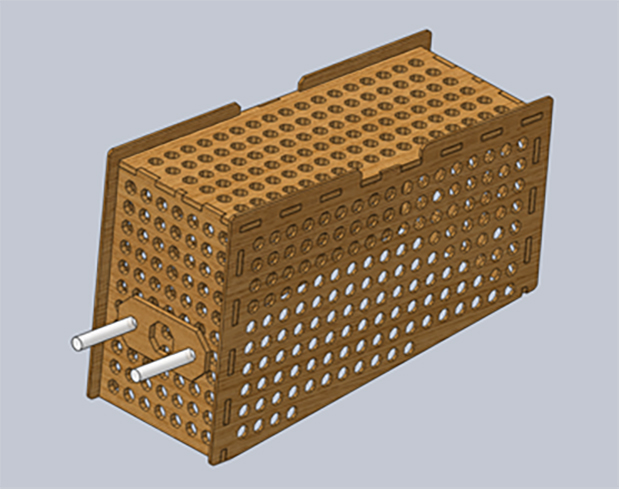

This project is a set of instructions for building and installing a payload box and drop mechanism for the X-UAV Talon R/C airplane. Design credit goes to Brandon Fetroe of Uplift Aeronautics.

The files for the custom parts can be found here on Uplift’s Github.

The system consists of three major components:

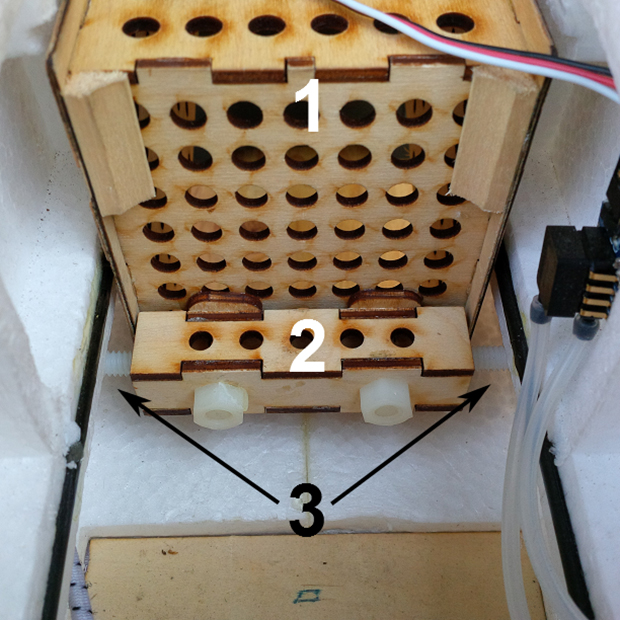

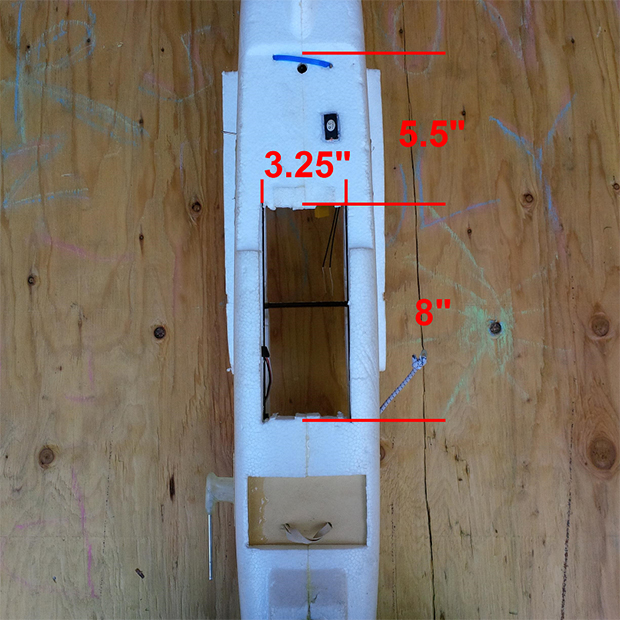

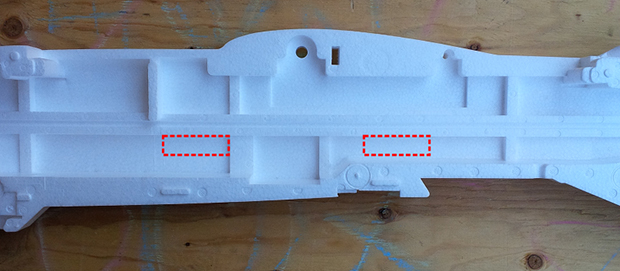

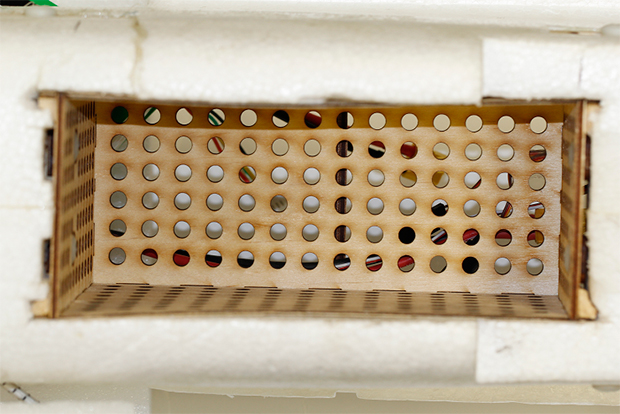

- The payload box provides a space to store and secure the payload in the fuselage of the X-UAV Talon. It is recessed into the body of the aircraft through a hole cut in the bottom of the fuselage.

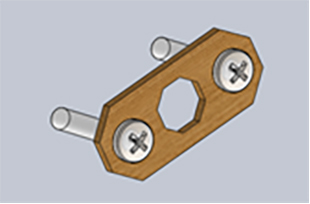

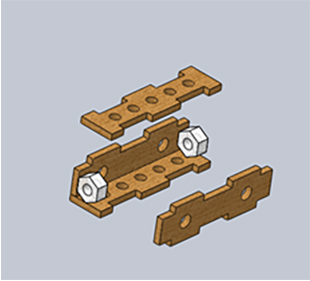

- The payload box is secured to four mounting brackets glued into the sides of the airframe. Four nylon bolts attach from the outside to hold it in place.

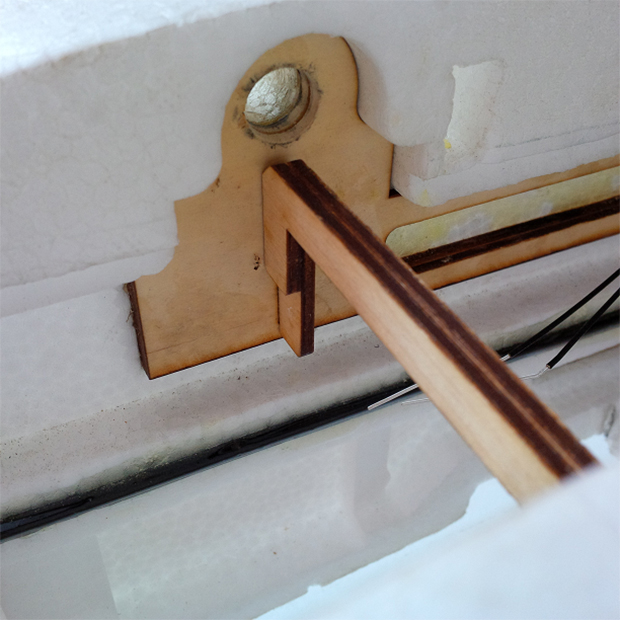

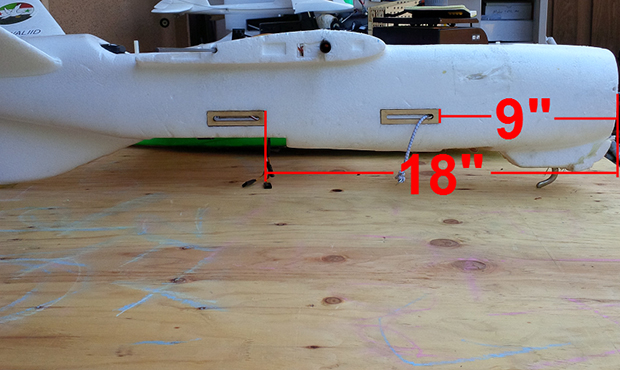

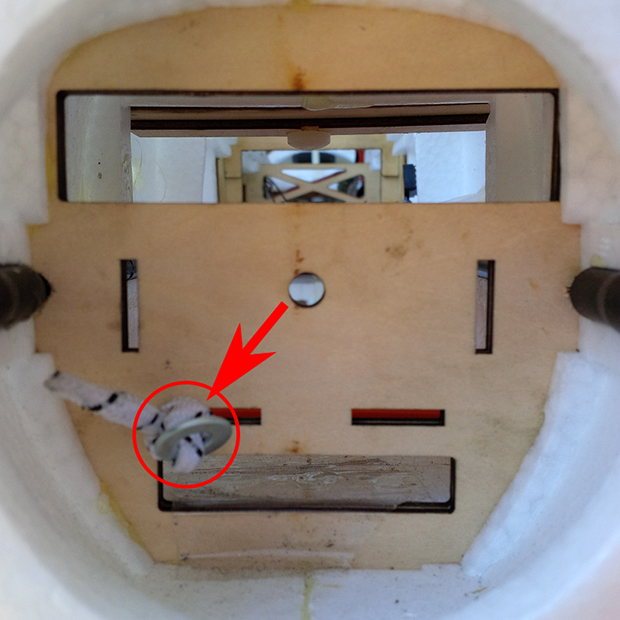

- The drop mechanism is a servo that extends and retracts a metal pin poking through the side of the body. A bungee cord wraps around the bottom of the payload and attaches to the pin to hold it in place.

The package is secured inside the airplane by a bungee cord tied at one end to the wooden plate in the nose of the aircraft. It is then stretched across the payload box opening to a pin on the opposite side. When the servo retracts the pin, the bungee will release and drop the payload.

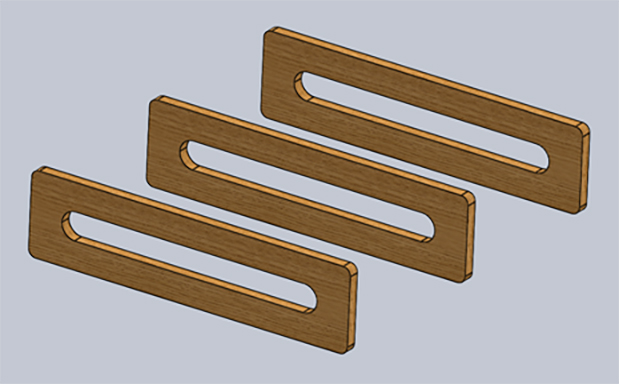

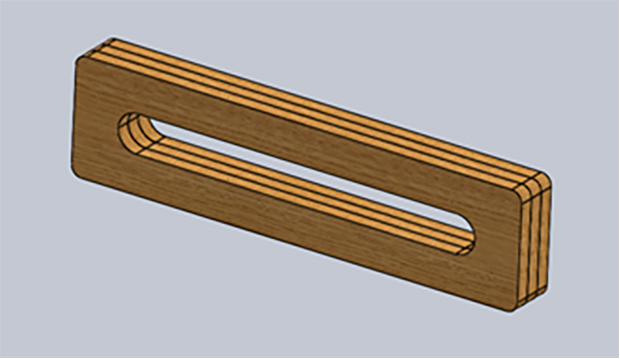

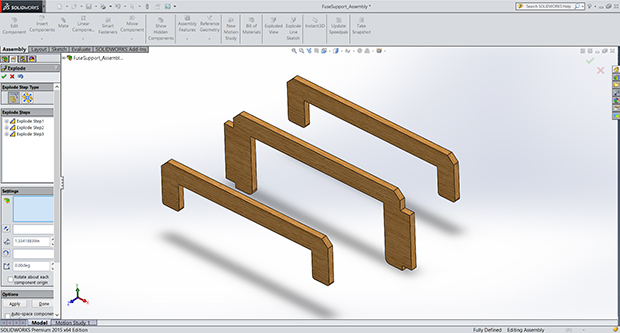

Most of the custom parts were laser cut out of 1/8″ or 1/16″ plywood, with files provided in the Git repository. In the absence of access to a laser cutter, most parts can be cut with hand tools, omitting the grid of holes in the box (done to save weight). SolidWorks part drawings are also available to work from in the repository.