I am a big fan of garage sales, flea markets, and thrift stores. They are great places to find used parts and materials for your next project. But one problem that I often run into is not being able to test battery powered electronics to see if they work. Because there are so many different combinations of batteries that are used in portable electronics, it isn’t really practical to carry around batteries for testing.

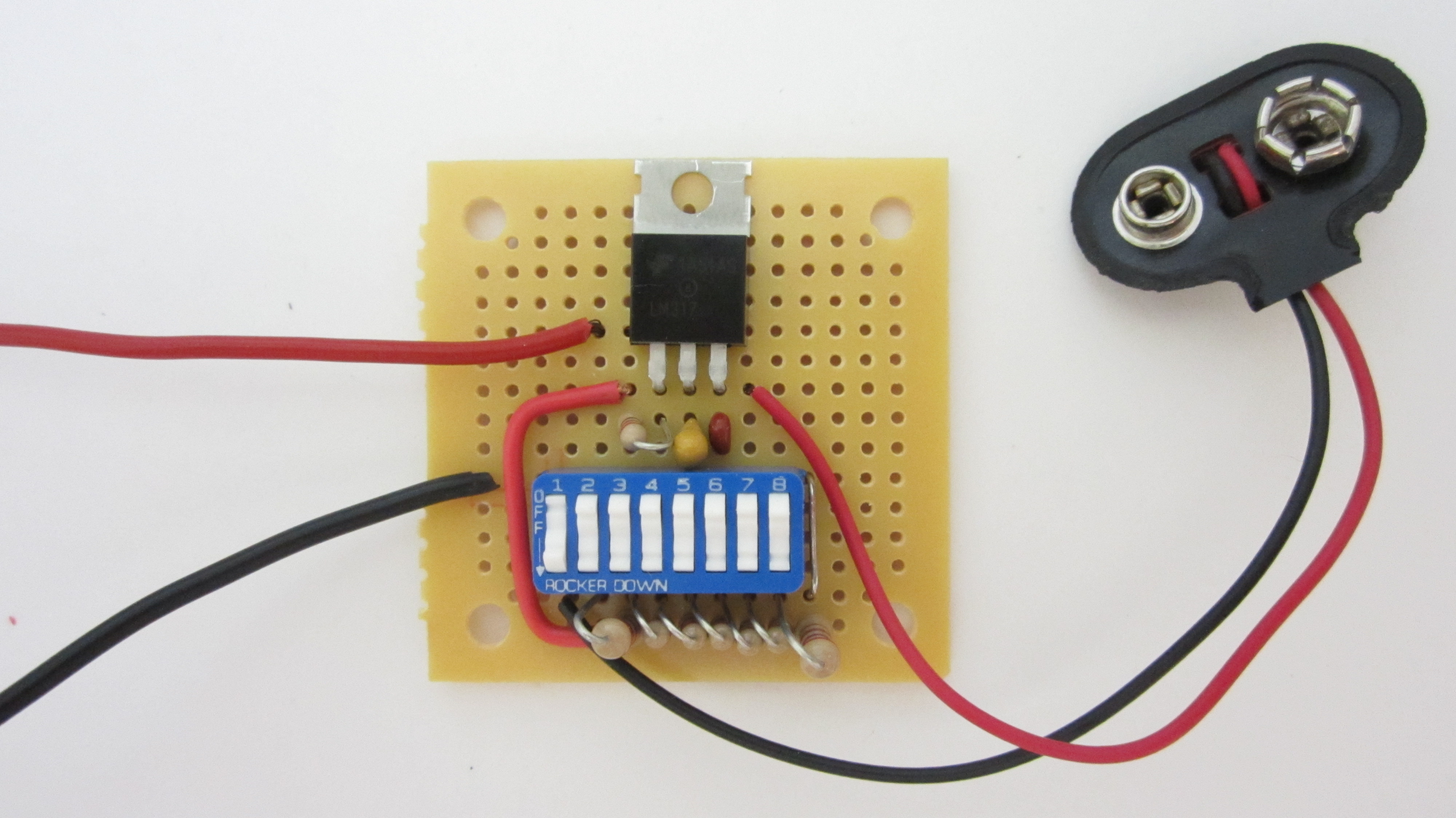

One device may need 6 AA’s and another may require 4 D’s. So I came up with this simple pocket-sized variable power supply. It can plug into either a 9V battery or a 12V battery pack. You can then adjust the output voltage to match the device that you want to test and attach the output wires to the end terminals on the device’s battery connectors. This lets you power the device long enough to see if it works.