Conclusion

NOTE: If your solar tracker doesn't track the sun accurately, the solar cell may be receiving too much reflected light from low clouds, brightly painted walls, or other nearby surroundings. Try painting the shade black underneath, and/or taping over unneeded portions of the solar cell.

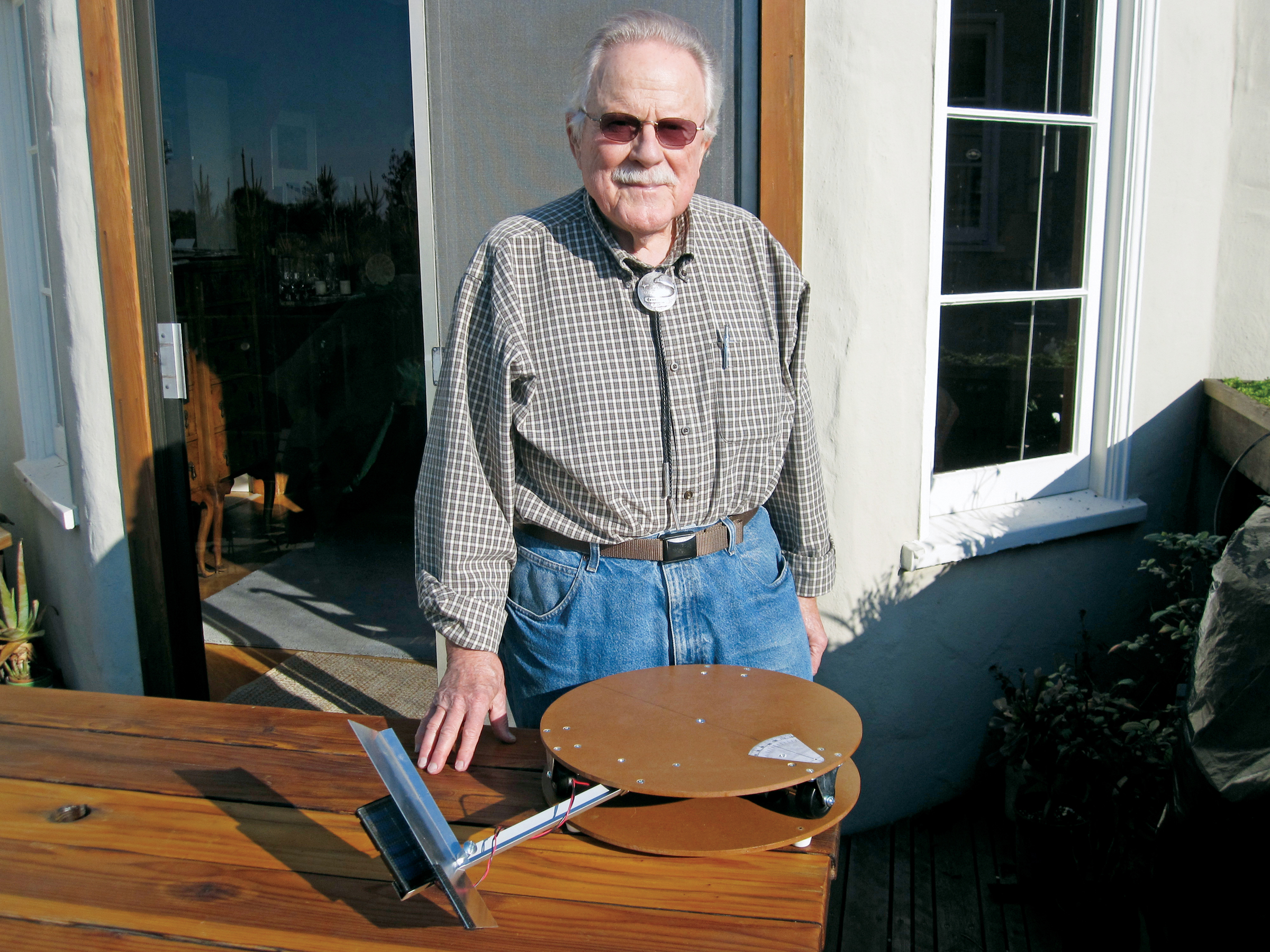

Cook Up Some Sol Food

To use the tracker, bring it out into the sun, give it a few minutes to start tracking, and position your ingredient-filled cooker and reflector on top, aligning it to face along the central tracking angle (determined in Step 11). Then, just let the sun do the rest.

With my solar tracker, the motor kicks in when about ½" of the PV cell comes into direct sun, which means about 75% of the cell stays in the shade. The platform rotates about 4° for each correction, so it tracks the sun’s motion with an error of ± 2°.

In the San Francisco Bay Area from about March to November, I have had particularly good results cooking Cornish game hens with vegetables, tandoori-style chicken, burgundy beef stew, salmon loaf, lentils, beets, and potatoes.

Most one-pot slow-cooker recipes will work well, and I look forward to expanding my repertoire. Crock-pot or slow-cooker cookbooks will yield a wealth of ideas, and some of my favorite recipe sources are listed at https://makezine.com/volume/make-22.

I tested my HotPot solar cooker on a clear day last May, putting 750ml of canola oil in the pot at 10:10 a.m. It took about 45 minutes for the oil to reach 212°F. The pot stayed above 212° for 6½ hours and maxed out at 315°.

If your cooker gets too hot, rotate it (not the platform!) counterclockwise so that it will track some number of degrees behind the sun. But don’t apply torque to the drive wheel in the process!

Depending on your space limitations and the season, you may choose to leave the platform with its boom extended and solar cell attached for months at a time, but don’t leave it outside when you aren’t using it.

Other Applications

Beyond cooking applications, you can also use the platform to speed up photovoltaic battery chargers. And someday, someone who is experimentally inclined might conceive of a neat way of adapting this device to also track the sun’s altitude, or to orient a solar-powered food dehydrator, or to distill seawater. The possibilities are fun to contemplate.

This project first appeared in MAKE Volume 22, page 101.