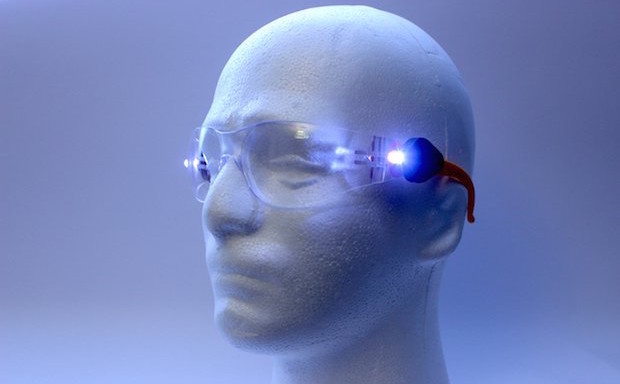

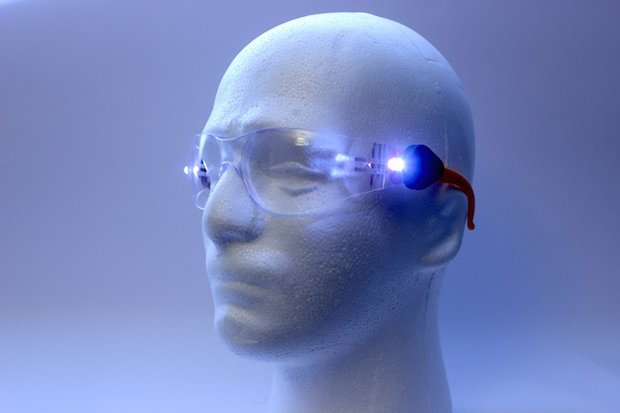

You’d be amazed at how much better your projects turn out when you can actually see what you’re doing. The trouble is, flashlights are easy to misplace and they’re difficult to hold onto when your hands are occupied with a project. To solve the problem, we’re going to hack your safety glasses with some useful, rotating, detachable LED lights.

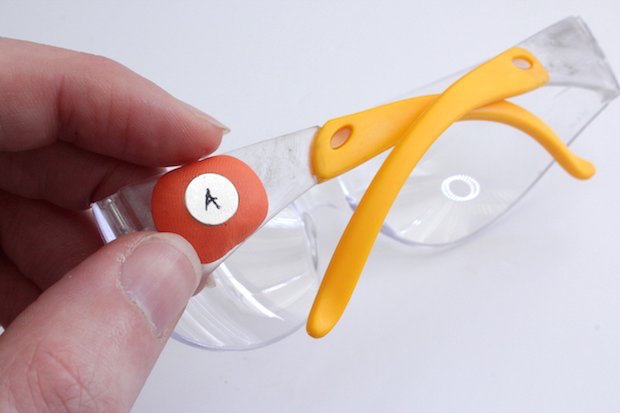

These magnetic lights (or “Mag-Lights”) stick to the side of your workshop glasses, allowing you to direct light to illuminate where you are working.

These headlight glasses are just the thing for anyone working in tight/poorly-lit corners, such as plumbers, electricians, and DIY enthusiasts who may well need to wear eye protection anyway. This only adds about 0.5oz to your glasses, but delivers a lot of illumination. In addition, the magnets allow the lights to be detached and repositioned anywhere, from metal surfaces to being combined with tools.

This idea originated from speaking to a friend who wanted to BBQ late into the night, but wanted to have a cheap, hygienic, and repositionable light to check if the meat was cooked. The Mag-Lights were an evolution of just experimenting with this idea and realizing the potential of using magnets as a rotational mechanism.