Wooden Screws Part II: As part of my continued exploration of Leonardo Da Vinci mechanisms, I needed to produce several different kinds of lead screws and nuts for my projects. While commercial wood taps and dies are relatively inexpensive, I wanted to make my own, so I could get the right diameter and pitch. During my efforts I tread making several different kinds of taps, but wasn’t too successful making the old-fashioned screw boxes. Information on doing this can be found in Roy Underhill’s books on woodworking.

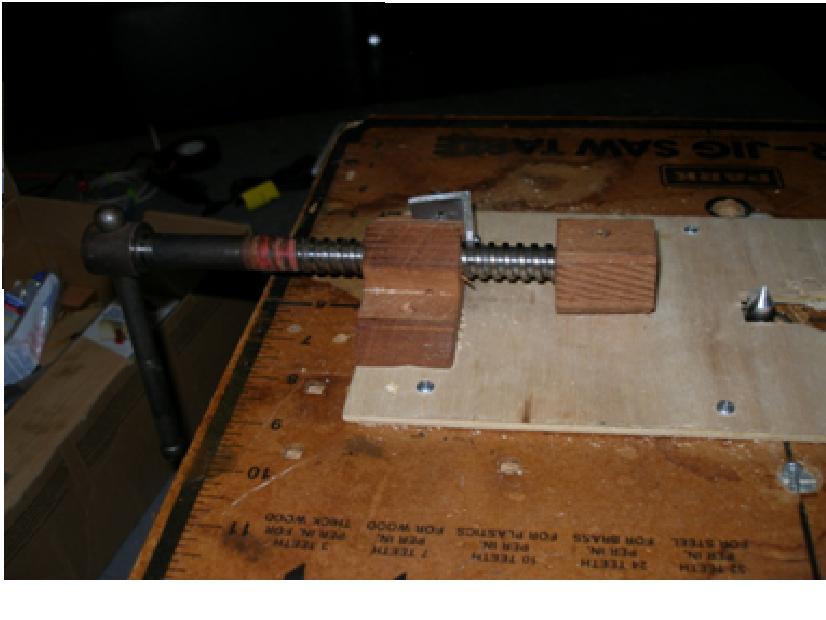

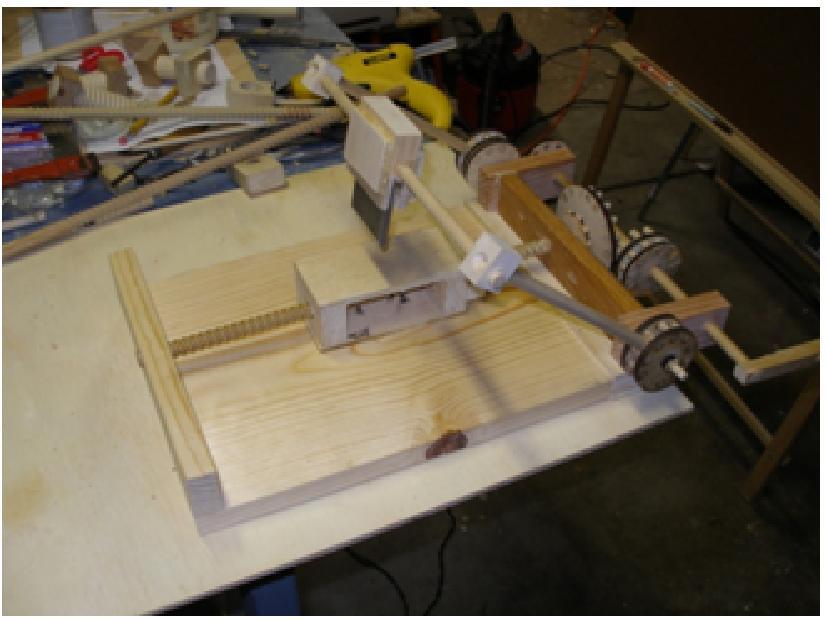

There is another technique for making wooden screws on a wood lathe called “chasing threads” but this takes special equipment and years of experience. Eventually, I built a couple of “screw duplicators” using a table-mounted router and salvaged lead screws, and these worked very well.