O’Reilly Media held its annual Solid conference this week in San Francisco. It’s an annual show covering “Hardware, Software & the Internet of Things.” We found it eye-opening, informative, and occasionally controversial. Here’s some of what we heard at this year’s show:

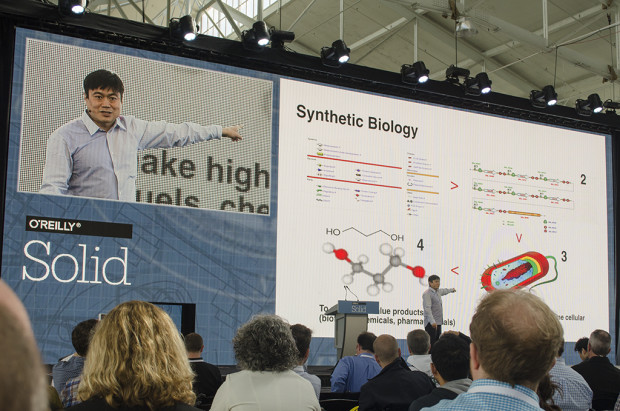

Synthetic Biology

Joichi Ito, Director of the MIT Media Lab, explained that code is now being used for genes that can be printed into bacteria.

He predicts that a Moore’s law for biology is taking hold, accelerating biotech at five or six times the speed of internet or hardware innovation. In fact, he says, you can now do bio experiments in your kitchen that two decades ago would have won a Nobel prize. From his vantage, the future is in the convergence of hardware, software, and biology.

Other Machine and the Other Mill

Danielle Applestone, CEO of Other Machine Co., which makes the Othermill desktop CNC mill, talked to the makers trying to bing a product to market. She discussed the need to deliver a personal experience along with a product, but she outlined a few looming issues for small hardware manufacturers:

- The hardware climate is difficult.

- Margins on physical goods are really, really low.

- Contract manufacturing companies are operating on 2–3% profit margins.

- All new hardware, software, or services will eventually be commoditized.

So how can small manufacturers make it?

Personalization, she says, works as a differentiator. Applestone’s example is buying pants. Most pants that people buy are not made custom for them. instead the entire manufacturing arrangement is about approximating everyone’s needs and manufacturing products in sizes that fit most people approximately, but nobody anyone well. She sees this lack of specificity as a problem and an opportunity. Why don’t consumers demand having their bodies scanned and clothing made on demand to their measurements?

If companies manufacturing mass quantities can’t address this need, smaller manufacturers can, by personalizing products for the consumer. She believes that products which meet consumers’ specific and personal needs will thrive, regardless of size of the company behind them. In fact, she feels this is the only way that small hardware companies will survive.

Electronic Frontier Foundation

Cory Doctorow’s keynote provided an overview of the destructive and freedom-restricting nature of the Digital Millennium Copyright Act (DMCA). As noted on the Electronic Freedom Frontier’s website (Doctorow is an advisor to the EFF), the DMCA has two major sections which should concern anyone who interacts with computational devices.

The Digital Millennium Copyright Act (DMCA) contains two main sections that have been a source of particular controversy since they went into effect in 2000. The “anti-circumvention” provisions (sections 1201 et seq. of the Copyright Act) bar circumvention of access controls and technical protection measures. The “safe harbor” provisions (section 512) protect service providers who meet certain conditions from monetary damages for the infringing activities of their users and other third parties on the net.

Unfortunately, Doctorow said, there is no way you can completely avoid giving money to companies that “want to destroy our freedom on the internet.” So he suggests you counteract that fact by taking a percentage of the amount you spend with those companies and donate it to the Electronic Frontier Foundation or other Internet based advocacy groups.

Pop-up Factory

One of the more interesting aspects of the conference was the microfactory set up to manufacture and assemble Alike devices at the conference. The microfactory was a collaboration between designer Marcelo Coelho, Seeed Studios, Formlabs, Proto Labs, and ANT Wireless.

It made wearable light-up devices that Solid attendees wore. They devices lit up green when one wearer was next to another with similar interests, based on responses to a survey on a mobile app.

Case fabrication was handled by an army of Form 1 printers.

The boards, which were pre-fabricated before the conference, had solder paste applied and were put in a pick and place machine for component placement.

The boards were reflowed using a reflow oven.

The soldered boards were tested and firmware was flashed.

Finally, the case, wristband, and PCB were assembled into the final device.

Next year, Solid will be returning to the Fort Mason Center in San Francisco, April 20–22. If you’re interested in the future of hardware, software, and synthetic biology, we highly recommend it!

ADVERTISEMENT