I met Pat Starace last November at Maker Faire Orlando where he exhibited a toy Batmobile that he had outfitted with a jet engine. Pat is a professor at Full Sail University in Orlando with an incredible background and amazing stories. When I saw that he had developed a ventilator, I reached out to him and we talked by Zoom. On the Zoom screen, he was identified as Anthony Patrick Starace. I asked him about it. He said he was part of an Italian family and he was named Anthony after his uncle. However, around the age of two, his father had a falling out with his brother and said that he never wanted to hear the name “Anthony” in the house.

Pat has many stories, some of which he shares in my interview with him at the end. The StarVent enterprise is yet another episode in his life as a maker.

— Dale Dougherty

StarVent is a single cam bag-valve-mask (BVM) or Ambu-bag style ventilator at the prototype stage.

Build Day 0 – The Design

Figure 1. Rendering from my Solidworks assembly, and that’s the culmination of three weeks of work down to every screw, nut, bushing, latches, stepper, etc.

Today is the day I start fabricating a ventilator. I spent the last three weeks working hard designing this single-cam ventilator which will automatically compress a FDA approved BVM (Bag Valve MasK). I saw something like this from MIT but the plans weren’t available. I opted for a single cam mainly because it has fewer moving parts than a dual cam, and I also designed it to have dual spur-gear drive for reliability. The cam is driven by a stepper motor that is geared 8:1 which should be more torque than what is needed to compress the BVM. A microcontroller allows control of tidal volume and breathes per minute and also has a pressure sensor alarm. Sourcing parts has been quite difficult with the demand and restraints on the supply chain, but I managed to find the right sources to complete the BOM for this vent.

Prototyping the first of anything always costs a small fortune, and this was no different, though I do estimate that subsequent units could cost in the range of $300 to $400 dollars. I’m not sure where this project will go, but if I can somehow save even one life it’ll be worth it.

Build Day 1

Figure 2. Laser cut acrylic enclosure

Day one building the ventilator is in the books and Full Sail University laser rocked it. Of course there was a little blood and fire, but I’m glad to have gotten this out of the way early in the day.

Build Day 2

Figure 3. Long workbench full of parts

Lots of drilling and tapping threads for the screws that hold it all together, and it’s amazing how great it all fits together. The cam is in place, and the control panel has been cut out with Full Sail University laser. The Ventilator is coming out better than I thought, and it’s exceeding my expectations. This is a real-world application and how I teach my students that you can realize your dream with a well thought-out plan. You can “Dream It Make It”. I can’t wait to peel off the paper…

Figure 4. Testing the bag

Build Day 3

Figure 5. Completed assembly

Day 3 working in the Pat Cave. A lot of tasks were completed. The cam, shaft, bearings and collars are aligned and complete. After completing the assembly of the cam, I realized there’s a certain beauty in this mechanism, it’s so shiny. When time allows, I’ll be printing the cam gears out of nylon.

Figure 6. Acrylic Cam

Figure 7. Another view of Cam

Figure 8. Third View of Cam

The shaft spacers didn’t fit, and were oblong instead of round. I had to re-cut them on the Full Sail University laser, I guess there was too much heat for such a small part so I did multiple passes and they came out great. I 3D Printed the cam position sensor mount and the self aligning motor mount. I used a new type (for me) of 3d printing plastic called Colorfabb Ht Clear made out of a plastic called Amphora. It has a high transition temperature and I print it at 280c. It machines great and is FDA approved. The power supply is installed and wired with an additional run to power the fan. It shouldn’t be long now, next is to cut a circuit board and start programming.

Figure 9. Stacked Buck Converters

Build Day 4

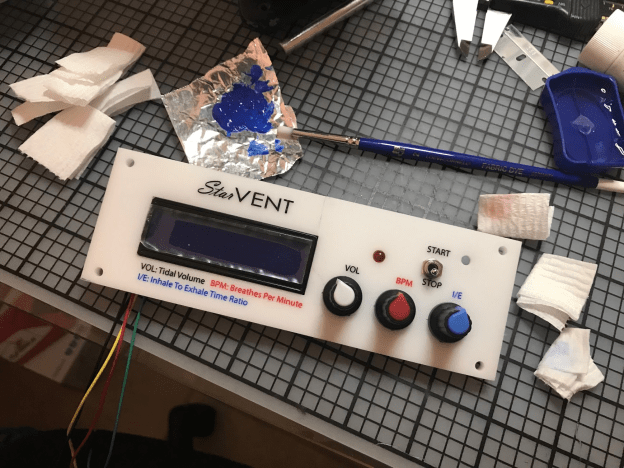

Figure 10. StarVent Console

Control panel has all its components installed and has been painted. The panel shifted a little when I engraved it on the Full Sail University laser, but it still looks pretty good. I drew a schematic of the electronics, and now all I have to do is wire it up and it’ll be moving.

Figure 11. Schematic drawing (by hand)

Build Day 5

Pat was busy teaching classes and made little progress on Day 5. However, the video below shows how Pat’s students sometimes see him as “Red Leader” streaming from a VR simulator. (no sound)

Build Day 6

It’s starting to move! Here’s a first motion test video. There were quite a few problems to solve.

First, I spent many hours trying to get the stepper driver I spec’d out to work, just to realize that no matter what I tried it still failed. Not having another around, I grabbed an old driver I had for my Bukobot (my first 3D Printer) and it was exciting to see the vent start to move, but there was considerable vibration from the stepper motor. I was on the right track, but I need finer control of the stepper and this driver didn’t support microstepping. I remember that Deez (from Deezmaker) sent me an updated driver board for my Bukobot when I was making The 3D Printed Kids Iron Man Prosthetic Hand and lo and behold these newer drivers support microstepping and the vent was moving much much better.

Figure 12. The stepper driver has a custom PCB with a 3D printed mount that incorporates a small fan to keep the driver cool.

There is still a vibration resonance through the acrylic and I’d like to overcome this so this vent is pretty quiet. I’m printing the gears out of nylon so that should help as well as adding some isolation where the mechanics meets the acrylic and I’ll be heading into Full Sail University FabLab to mill some pockets for sound dampening bushings. Also, I could use a little more torque, so I have new pinion gears coming. It’s great to see it start to move, and the first of anything is always the hardest and this is a testament to perseverance and dedication to making a dream a reality.

Figure 13. The brains of the StarVENT is an ESP32, and to utilize space the terminal blocks were mounted on the bottom so the wires would channel out in one clean bundle.

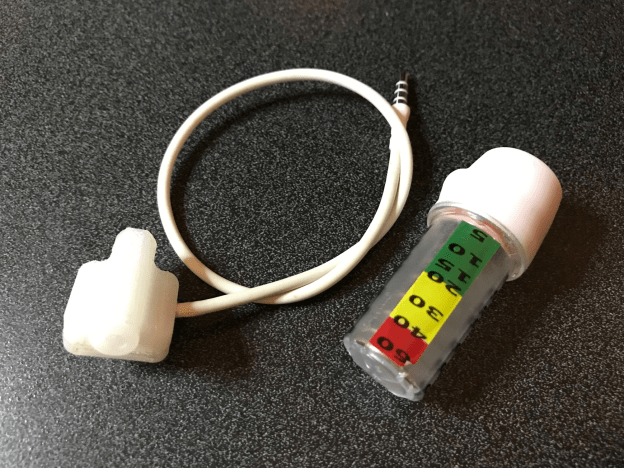

Figure 14. The Pressure Sensor is a BMP180/280 mounted in a sealed housing 3D Printed in nylon. The sensor connects between the BVM and the Manometer and regulates and monitors the vent so it stays within safe pressure levels.

Build Day 7

Figure 15. Cam made from nylon

Noise Reduction – Nylon and Silicone. Though it’s exciting to see it move, today I wanted to tackle the excessive noise I was getting through the mechanics. I want this to be a relatively quiet device, so I went about creating sound absorbing motor mounts and printing the gears in nylon. I wanted to set a baseline in decibels so I downloaded a decibel meter for my phone and took an initial reading. The vent came in at a whopping 78db — “Busy traffic, Vacuum Cleaner” and that was way too loud.

Figure 16. Small silicone tubes

After some preliminary tests, I decided to make these similar to common mounts in automobiles. I made them out of silicone rubber tube with an inner metal tube, which gets inserted into a new motor mount that I 3D printed. This should isolate the motor within the mount. I then went about printing the gears out of nylon, and this turned out to be quite a feat. Nylon has lubricating properties, and while this is great, it makes it difficult to 3D Print as it doesn’t like to stick to the printbed. I tried many different methods to get it to stick, and after many hours and many failed attempts, I finally got a method to work that is 100% reliable.

Figure 17. D printed housing

After installing the motor mounts and installing the gears, I took another sound reading and WOWZA, I reduced the sound by 20db. The vent came in at 58db — “Quiet office, moderate rainfall”. I think I can make this even better by adding noise damping to the cam, but I’ll save that for another day. One more day and this should be finished…

Build Day – The Finale

Figure 18. Completed StarVent Ventilator

The protective paper has been removed and it’s as shiny as I thought it’d be and has exceeded all expectations. With classes done for the week I had the time to finish this, plus some time to put myself back together after this intense build.

The programming became a task as the steppers are very dependent on a constant update rate and the LCD’s are notoriously slow to update and it caused the stepper smoothness to decline. Luckily the chip I used (ESP32) has two cores and I multi-threaded the LCD process to its own thread and the vent was happy again. I’m not exactly sure where this will go, maybe now I can now apply for emergency use FDA approval. Huge props to the FabLab’s awesome laser at Full Sail University. All in all, this was a testament to perseverance and dedication and now this dream has become a reality.

Figure 19. Pat with the StarVent

Interview with Pat Starace

I interviewed Pat on Sunday May 10 from the Fab Lab at Full Sail University, just a few days after he finished his prototype. As I mentioned, he’s full of stories so when I asked him about the “spark” that led him to develop StarVent, Pat talked about singing pineapples in hospitals, the Iron Man prosthetic hand, and even his jet-powered toy batmobile. But he also talked about what it means to make something as a gift to help others and how it keeps him going.

ADVERTISEMENT