Since my freshman year at MIT in 2007, I’ve been building small electric vehicles as a hobby (why walk when you can roll in style?). My involvement in the student project space at MIT ultimately spurred me to become a mentor for students building their own projects of all types. Interestingly, the most valuable advice I often gave was not how to make things, but where to get things.

In my years of building vehicles (and robots), I had unknowingly amassed a huge repository of places to buy or scrounge parts, and methods of vetting them for a design. These tactics proved indispensable: as it turns out, nobody teaches you these practical skills in engineering school.

The first time I saw the Power Racing Series (PRS) was at World Maker Faire New York in 2012 — grown adults racing heavily modified or custom-built Power Wheels cars to relive their childhood years. It got me thinking about how to channel my students’ efforts into a project that could benefit engineering education.

I began to write down and distill the rag-tag EV building methods that had been refined by students and instructors through the years, and in 2013, I taught the first semester of a lab class which would come to be known as “2.00GoKart” by the undergraduate population. I modeled it after MIT’s robotics-competition-focused course ME 2.007, but with students instead building electric go-karts in teams of two.

Students were forced to search for all their own parts, justifying to myself and fellow instructors why their part worked for their design. I ensured that everybody knew what McMaster-Carr was, how to find a certain sized screw there, and why certain decisions came back to bite them later in the semester (like, needing 5 different wrenches to tighten a motor mounting bracket).

If It Moves, Use It for Parts

With the “2.00GoKart” class increasing in popularity and the 2014 Power Racing Series rule revisions becoming ever more compatible, it was a curious case of convergent evolution. I decided to create a “technology demonstrator” vehicle for PRS 2014. After watching the 2013 race, I thought the sport needed an injection of varied parts and technologies. There were just too many salvaged floor-scrubber motors and forklift motor controllers for my liking.

My intent was simple: show that you can use parts from a variety of seemingly unconnected industries, sourced from internet shops and real-life stores alike, to create a highly competitive racing vehicle without a lot of sophisticated manufacturing equipment. The same theme would be useful to my students building practical vehicles, or really any kind of project: that you can use anything for parts. Here’s the story of the Chibi-Mikuvan.

Body Stylings

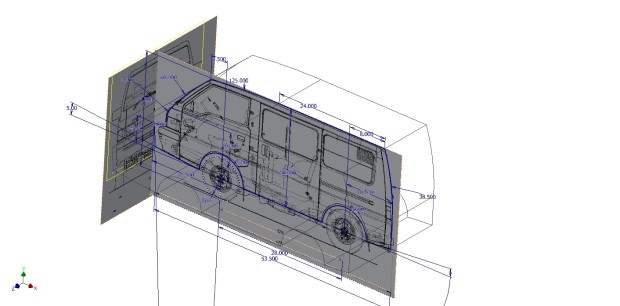

You might be thinking: That’s not like any Power Wheels car I’ve ever seen. Chibi-Mikuvan is basically what a Power Wheels version of my car would look like — specifically my 1989 Mitsubishi Delica van, an obscure model sold only between 1987 and 1990 in the United States. (Several PRS teams used this new “rule” to great effect in 2014.) To fabricate the body, I chose foam-cored fiberglass construction: lightweight, rigid, and easy to repair. I dedicated the vehicle to Hatsune Miku, a popular Japanese animated musical character.

Power System

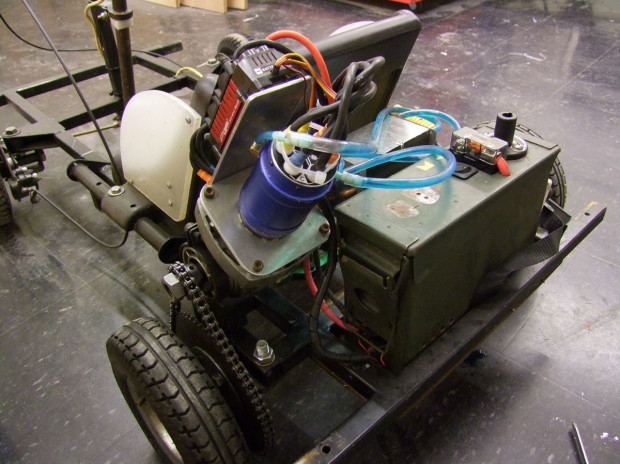

Chibi-Mikuvan comprises a mishmash of parts: an R/C boat motor, R/C car motor controller, angle grinder gearbox, pieces of a hybrid car battery, an ammo can, scooter brakes, wheelbarrow tires, an electric bike’s throttle lever, an Ethernet cable, and a USB phone charger. And of course, an Arduino.

My biggest “look for parts in everything” victory came in the form of the battery. In the Power Racing Series, batteries are not included — they count against your team budget, and the only way to achieve good runtime has been using lead-acid batteries, which are heavy and inefficient.

I began investigating nickel-metal hydride (NiMH) batteries, which were produced for the first generation of hybrid cars in the mid-2000s. I called no less than 15 auto parts yards and recyclers, and one Friday morning in October 2013, I drove from Boston to Burlington, Vermont to collect a $300 battery from a 2009 Ford Fusion hybrid to disassemble and turn into smaller modules.

The process is extremely dangerous, but in the end, I got four batteries for Chibi-Mikuvan out of one Ford Fusion hybrid pack. Ultimately the cost of each battery was only $37.50, and they weighed only 25 pounds.

Angle Grinder Gear Train

I wanted to experiment with using the latest generation of “giant-scale” R/C model parts, including motor and controller setups, due to their commodity status and low price. R/C motors, however, tend to be designed to spin very quickly with little torque. To tame that power for a ride-on vehicle weighing 100 pounds or more, I’d need a gear ratio of 20:1, compared to the average electric bike/scooter motor used in PRS entries of 5:1 or 6:1.

Creating a gear reduction from bike chain or commercial gears would have been too heavy and large, so I recalled an artifact from my younger years taking apart old power tools: angle grinders. What are they but a motor and a set of hardened steel gears in a premade box?

Mounting the R/C motor to the grinder’s gearbox would yield around 4:1, from which I could run a simple 5:1 chain drive using go-kart chain, with the result being the 20:1 needed.

Chassis and Brakes

The frame is simple welded steel tubing. Hand truck wheels (which didn’t last long under racing conditions) came from a local discount tool chain. The rear axle is supported in commercial steel bearing blocks. The only custom parts here are the massive 7″ front disc brakes, for which I used an abrasive water jet cutter to make the hub and rotor, pairing them with cable scooter brake calipers. The inside joke is that Chibi-Mikuvan can stop not only itself, but the three karts behind it.

Control Electronics

The interfaces between driver and motor controller live in a surplus ammo can. It’s waterproof, highly shock resistant, and easy to mount. I reused a high-current relay from the hybrid battery as a remote start; turning on the controller is a matter of pressing a small button on the handlebar. An Arduino Nano takes the analog throttle signal and converts it to R/C servo pulses for the motor controller. Since Arduinos can’t be powered straight from the 28-volt battery, I repurposed a cheap car accessory, a lighter plug USB charger, as a DC/DC converter.

Chibi-Mikuvan’s hodgepodge powertrain proved extremely quick, even if my prototyped electronics were unreliable — in 2014 it won a sprint race at Maker Faire Detroit and the quickest qualifying lap time at World Maker Faire New York. My hope wasn’t to make the absolute fastest PRS car, but the most documented and repeatable one, which can be used as a resource for anyone else. Complete build posts and bill of materials are on my blog.

ADVERTISEMENT