If you come from the banking and finance world, then you have heard about fiduciary responsibility. Since not many people jump from finance to electronics design, it is not a terribly important term to remember in the technological manufacturing world. However, change the “ry” to “l,” and you end up with fiducial — which can be quite important to electronics designers.

Purpose of a Fiducial Mark

Fiducial marks come into play when you have a PC board assembled by automated pick and place machinery — robots that put the components on your board. Automated assembly machinery requires incredible precision to accurately place a 0201 size resistor or 2mm x 2mm chip scale micro BGA. The machines have to know exactly where your board is.

A fiducial is an alignment mark for surface mount assembly machines. The marks ensure that your board is oriented in the correct direction and aligned as close to perfect as possible. Assembly machines use cameras to locate fiducial marks, and then adjust component placement based on the exact position of the board. The whole process typically requires more than one fiducial mark in a non-reversible pattern.

Take a look at the following two images. In both examples, one with three marks and one with two, it will be clear to the machine if the boards are upside down or sideways. The three mark pattern is recommended by the IPC, the keeper of industry standards. The second pattern, though it only has two marks and thus cannot be reversed, is seen often enough and also works.

When to Use a Fiducial Mark

High volume assembly always requires fiducial marks to ensure accurate registration and parts placement. Low volume assembly, like you would find at a low-volume or prototype specialist, does not always require them. However, since some low volume shops rely on them, ask before assuming. Even if fiducial marks are not required for assembling your particular product, they still help and are always a good idea. The only time that you can know for sure that fiducial marks are unnecessary is when you are placing your parts by hand.

In the image below, you can see three small metal dots (upper left, upper right, and lower right areas of the board). Those are the fiducial marks. If the electronics for this board were being placed by hand, the marks would not be necessary. However, because hundreds of copies of this board are being produced in an assembly line, it is important that the machines know the difference between the top/bottom and sides of the board. You do not want the electronics placed in a way that does not follow the designated pattern.

Construction of a Fiducial Mark

In terms of the specific construction of fiducial marks, two things are most important: position accuracy and contrast.

Position Accuracy

A fiducial must be created in the top copper layer. Why copper, when theoretically using a silk screen or drill hole would work? The answer is registration. All of the top copper is put down in one operation. Therefore, positional accuracy of a surface mount pad relative to a copper fiducial will always be the same. Silk screen and drill holes are added in separate operations, so there is always a chance that registration will vary from board to board.

A typical 0.4mm pitch BGA has a pad size of .254 mm (.01”), and has a space of .15 mm (.0059”) between pads. Silkscreen and drill holes simply do not have the precision needed for alignment at those geometries.

Contrast

The cameras in the machine need good contrast, which is why the mark has to be bare copper. Solder mask on top of a copper pad will lower the contrast to the point that the camera may not be able to see it. Solder mask has the same registration issues as silkscreen, so you need to make sure that no part of the pad is obscured.

Make the copper pad 1 to 2 mm in diameter. The mask opening should be 2 – 5 mm larger than the copper. Some CAD packages have fiducial marks in their components library. That would be the easiest route.

Shape of a Fiducial Mark

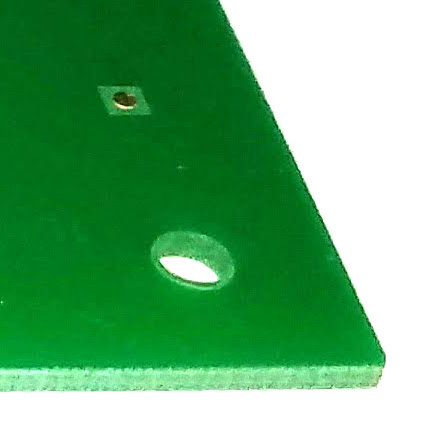

The next image shows closeup detail of a fiducial used on the board shown above. This particular fiducial mark uses a square cutout in the silk screen. Most use a round cutout, but the shape is not all that important. That being said, the copper pad should be round.

If your board will come from the fab house in a panel, you can put the fiducial marks on the panel rails. If you are receiving your boards as individuals, then put the fiducial marks on the boards themselves. If you are not sure, it is not a bad idea to do both. That way, whether the boards are assembled as a panel or the boards need to be depanelized before assembly, you are covered.

Remember, fiducial marks are not always required at low volumes. However, even if they are not required, they are still a good idea. A lot of quality in electronics is closely tied to risk reduction, and that starts with a good PC board design.

ADVERTISEMENT