The last couple of years have seen an explosion in home fabrication, with fantastic projects like RepRap and Fab@Home really helping to bring the open source community together. Unfortunately, 3D scanning — in many ways the flipside of the home fabrication coin — seems to have fallen by the wayside.

I decided to start the 3D scanning ball rolling by creating the SplineScan computer-controlled turntable. The turntable uses a gearbox for precise positioning, and has fixings for lasers, lights, and cameras. The obvious use of the turntable is for 3D scanning, although it can be adapted very easily to rotate objects for accurate photography or interactive display.

I’m currently using the turntable to archive and measure ancient artifacts as part of my Ph.D. studies (http://www.mara-3d.org), and I have to say that I’m very happy with the results so far.

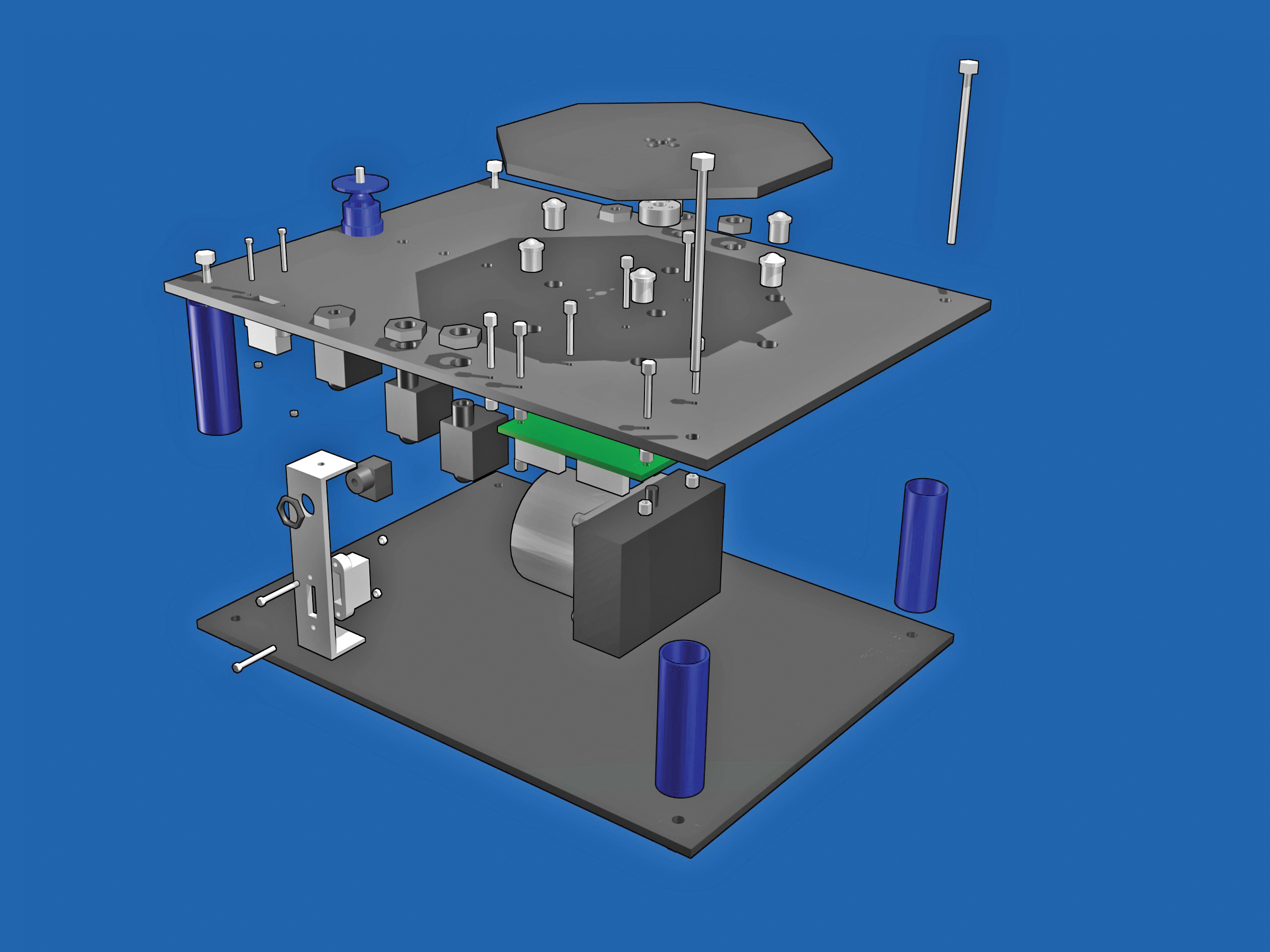

The parts list might look a bit daunting, but the project is not difficult to make. The scanner itself consists of 3 main parts:

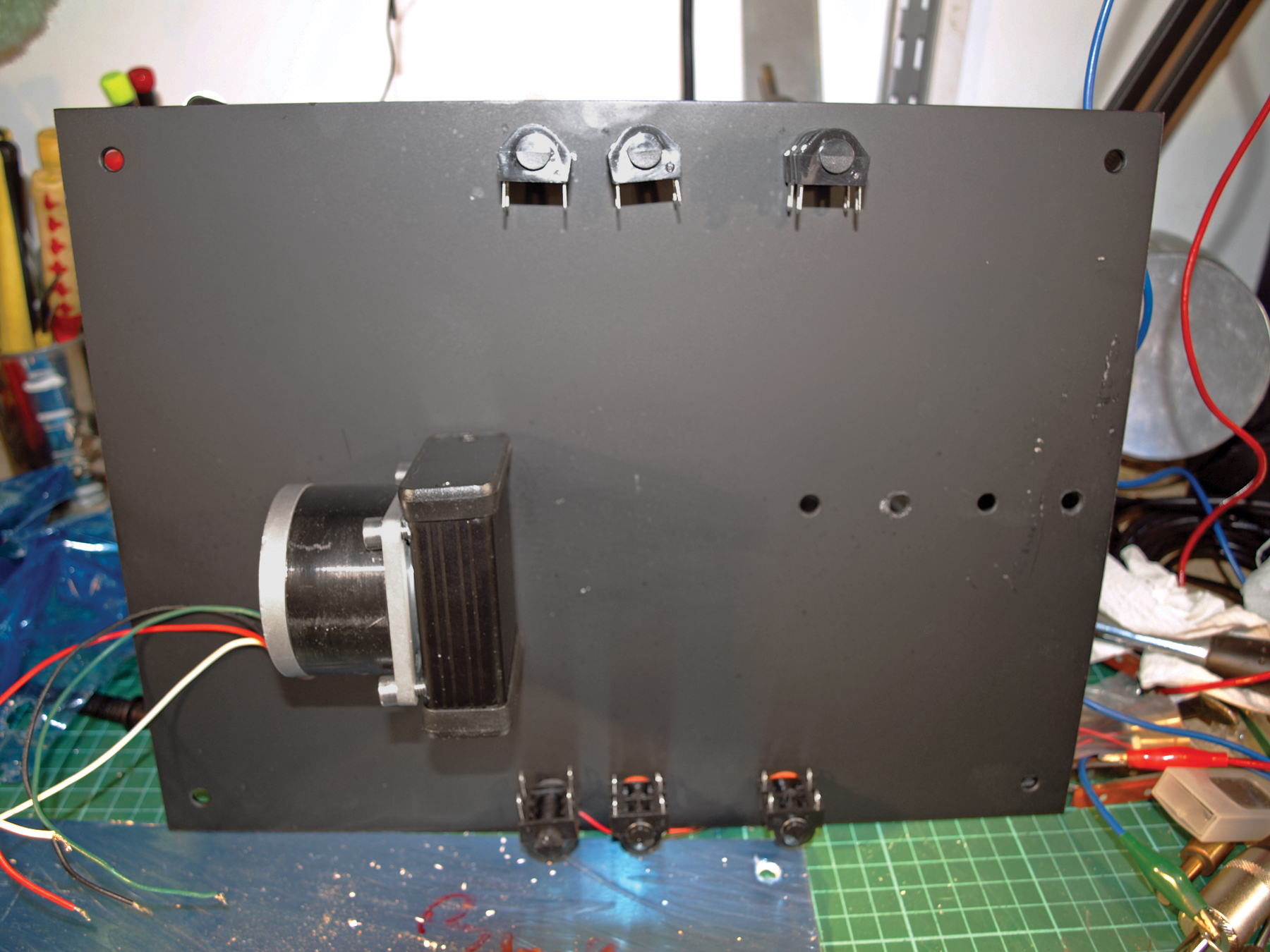

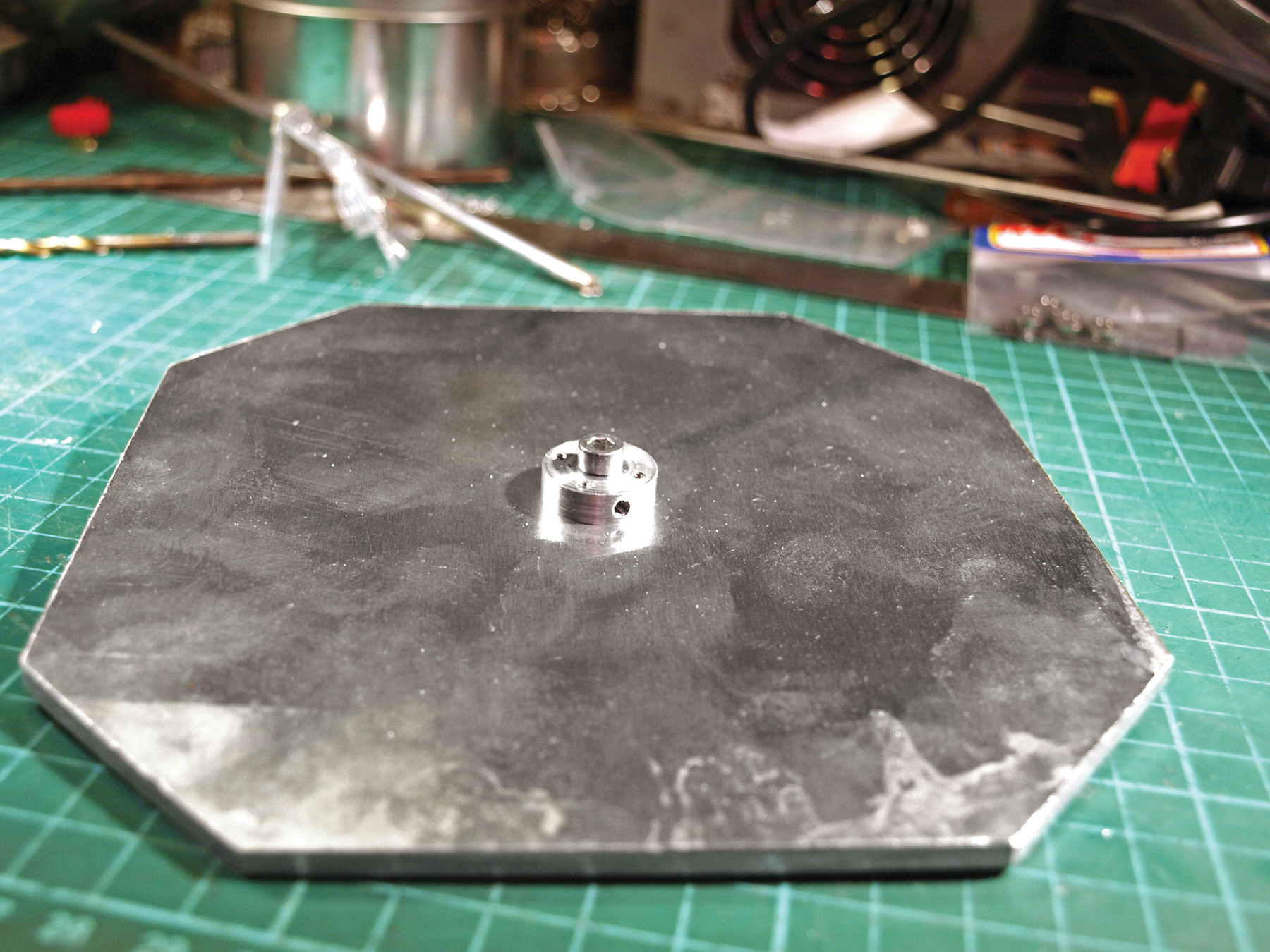

Chassis This is the backbone of the scanner. Everything fits onto the chassis, and it needs to be rigid enough to withstand the weight of all the other components, and whatever you intend to put onto the turntable.

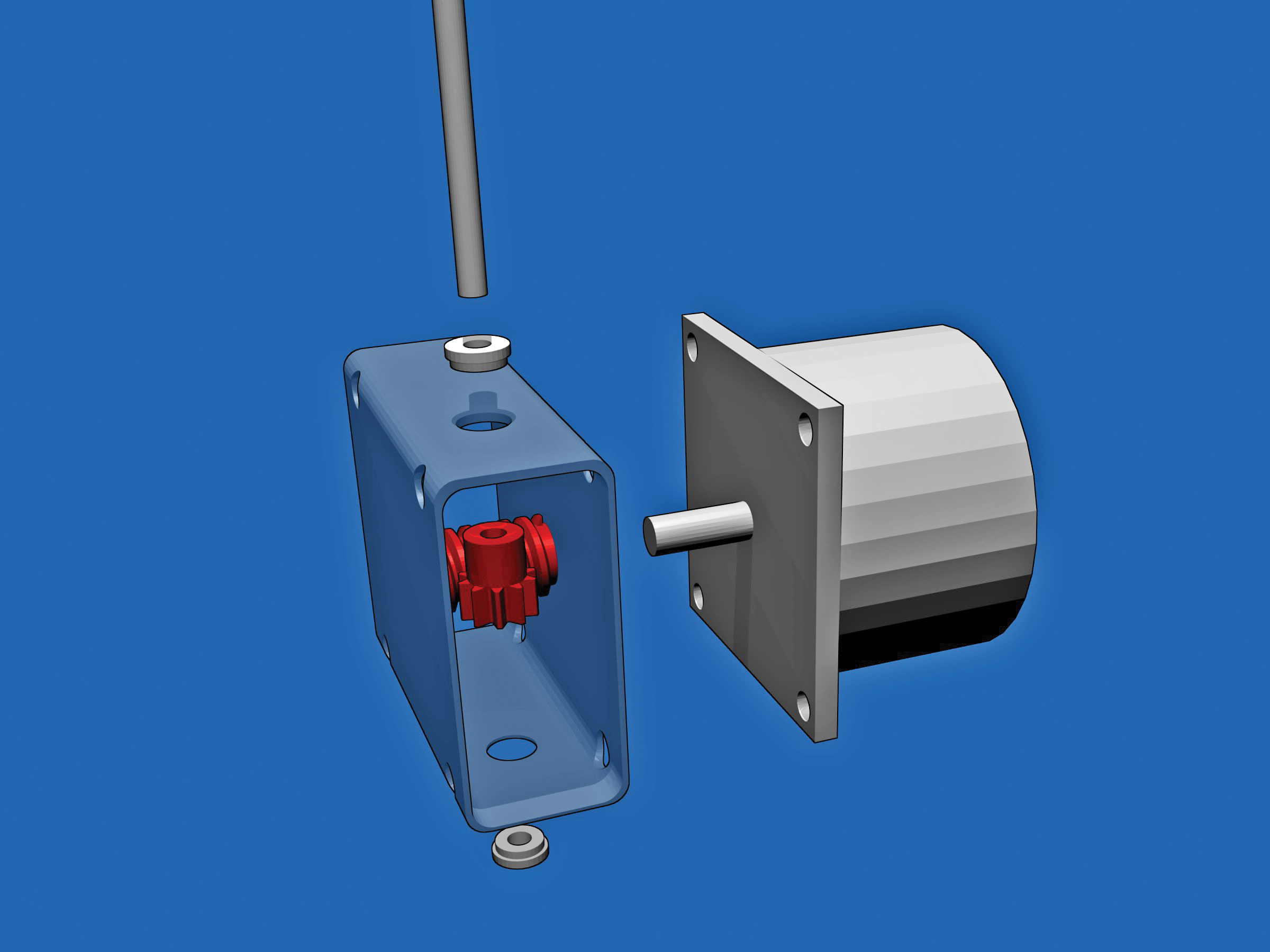

Gearbox This part takes the turning force of the stepper motor and turns it into something more suitable for our needs. It’s a simple design with only a few components.

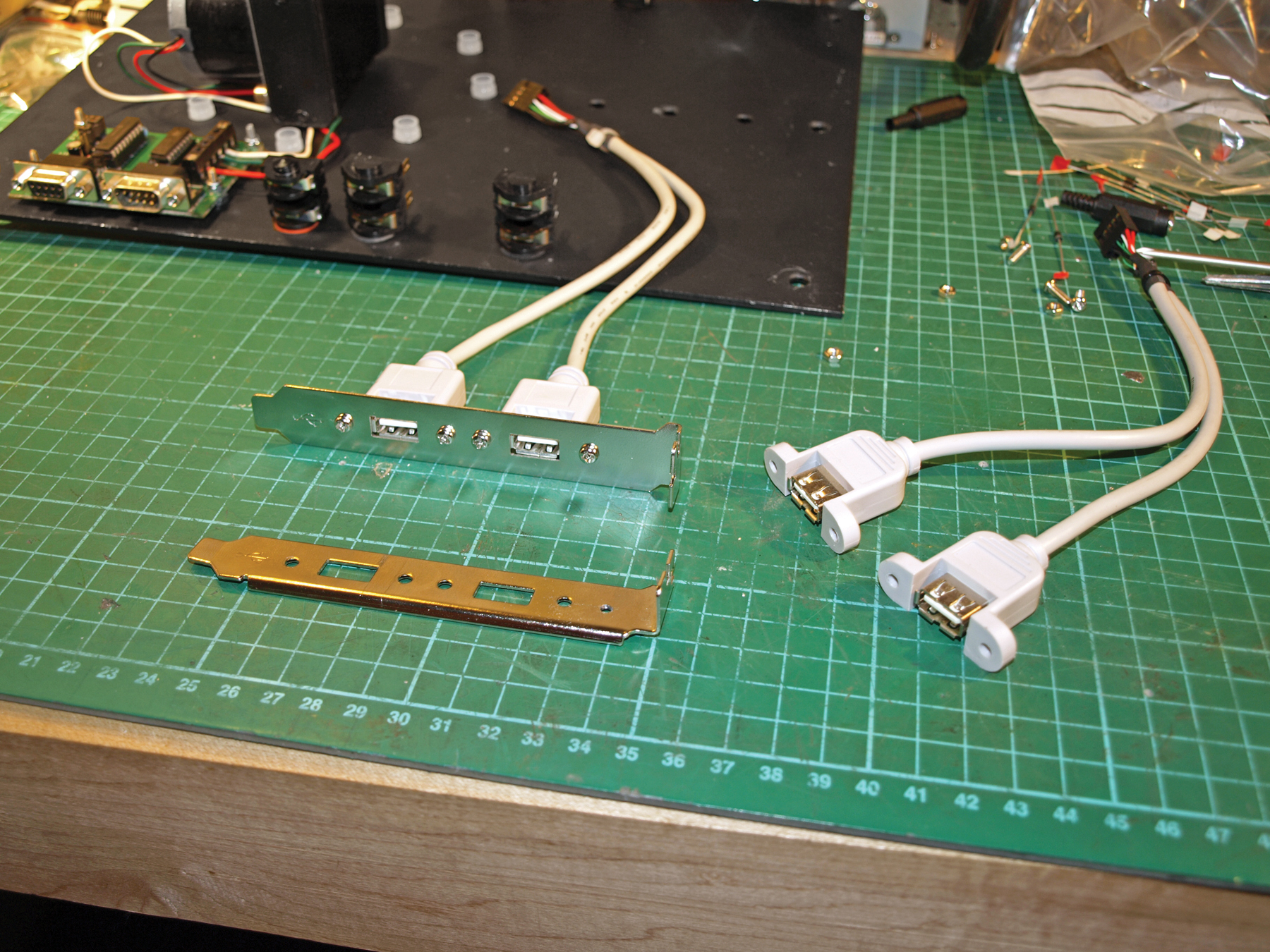

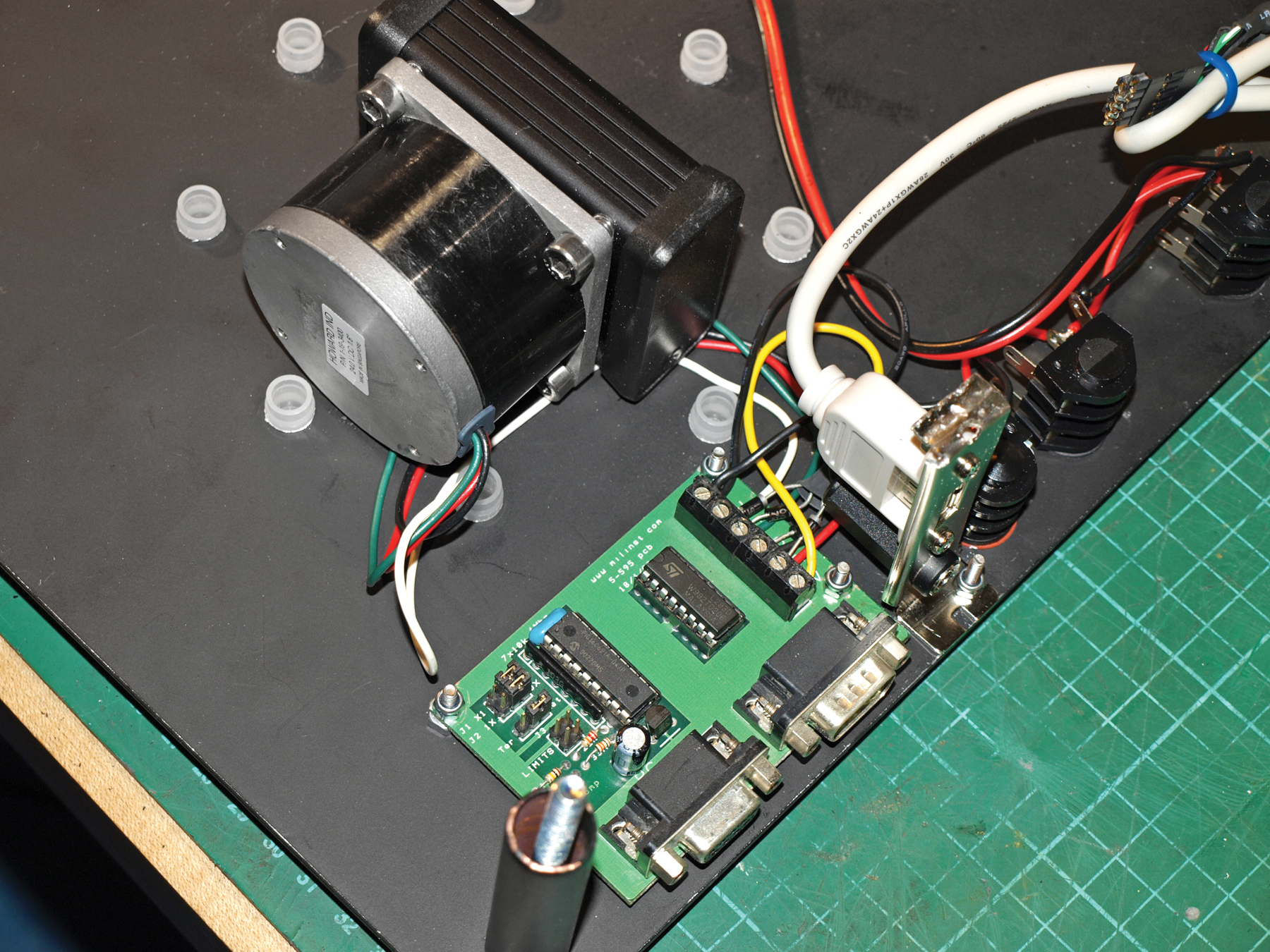

Electronics The brains and nerves of the scanner allow you control the turntable from your computer. The wiring is not difficult, and only limited soldering knowledge is required.