By Limor Fried and Phillip Torrone

We live in a rented apartment, so we don’t have hacking access to a power meter or breaker panel. But we still wanted to measure our household power usage long-term, so we developed the Tweet-a-Watt. It uses plug-in electricity monitors at each outlet to wirelessly send readings to a base station, which assembles them into reports you can analyze and graph. It can also broadcast updates via Twitter.

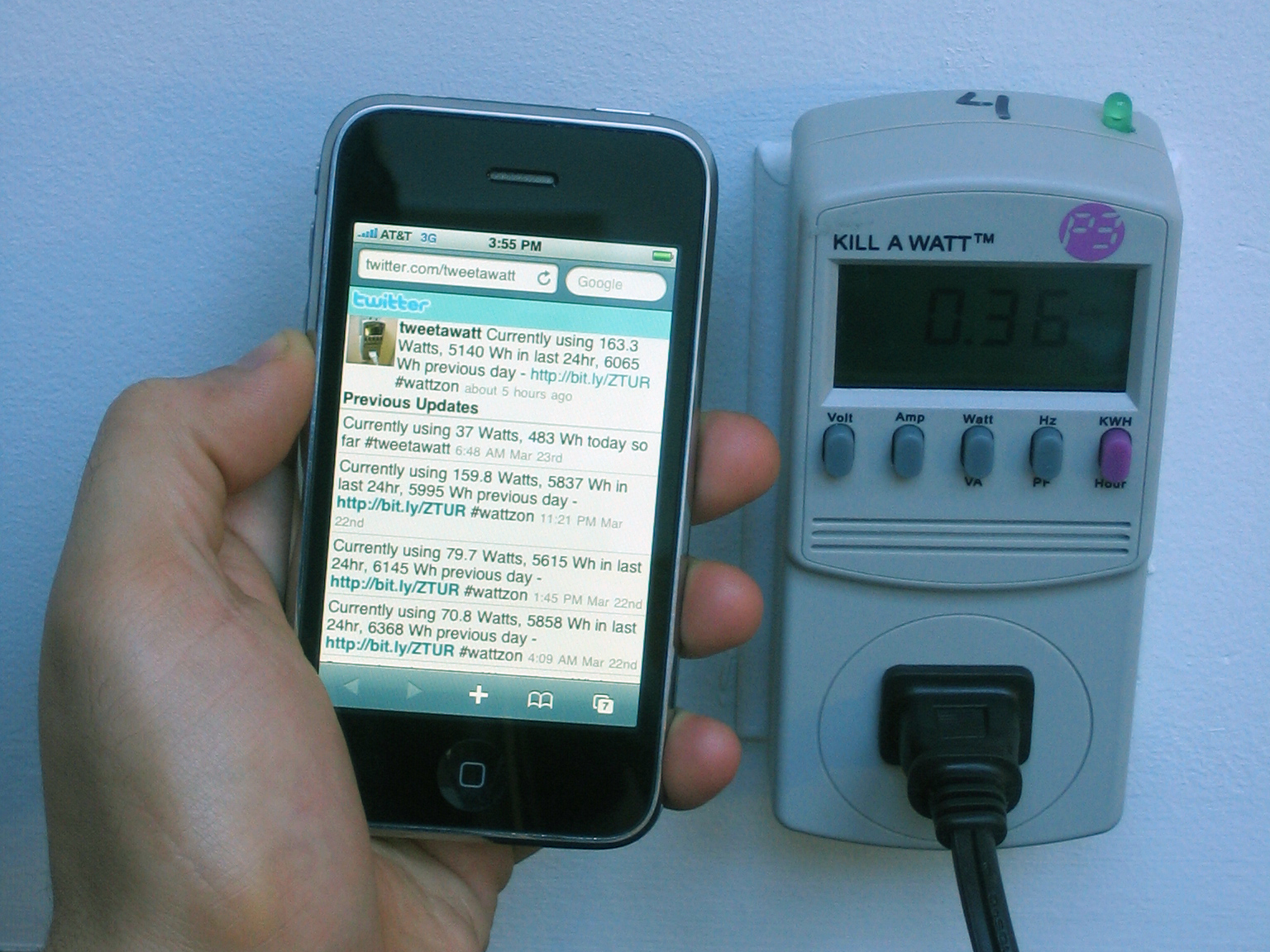

Building your own power monitor isn’t too tough and can save money, but we’re not fans of sticking our fingers into 120V wiring. Instead, we built on top of a P3 Kill A Watt power monitor, which we found at the local hardware store. To track usage room by room, for example “kitchen,” “bedroom,” “workbench,” and “office,” you can use a 6-outlet power strip in each room to feed all the room’s devices through a shared monitor. Each Kill A Watt can measure up to 15 amps, or about 1,800 watts, which is plenty for any normal room.

You can build each wireless outlet monitor for about $50 with a few easily available electronic parts and light soldering, and about the same for the receiver. No microcontroller programming or high voltage engineering is necessary!