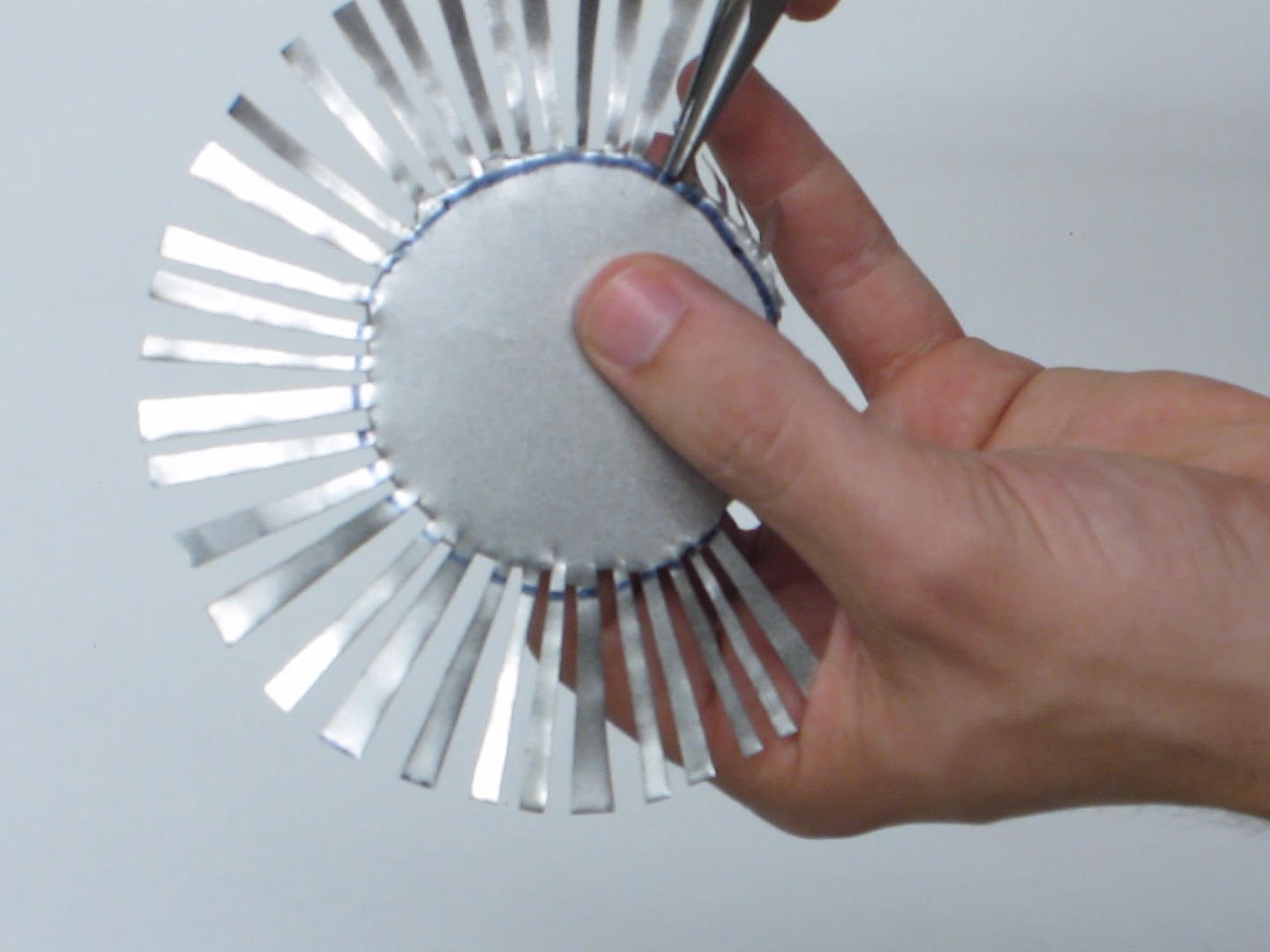

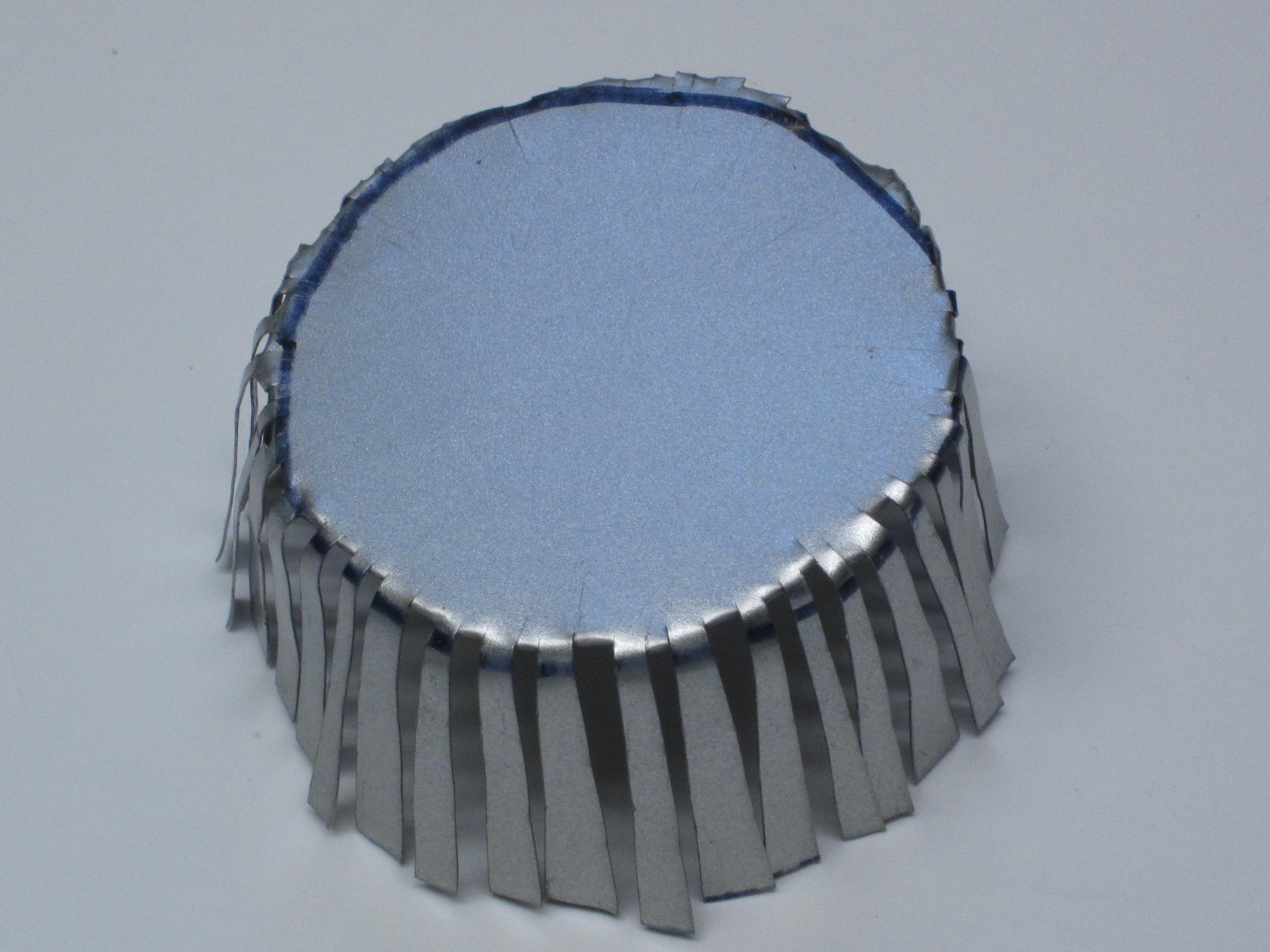

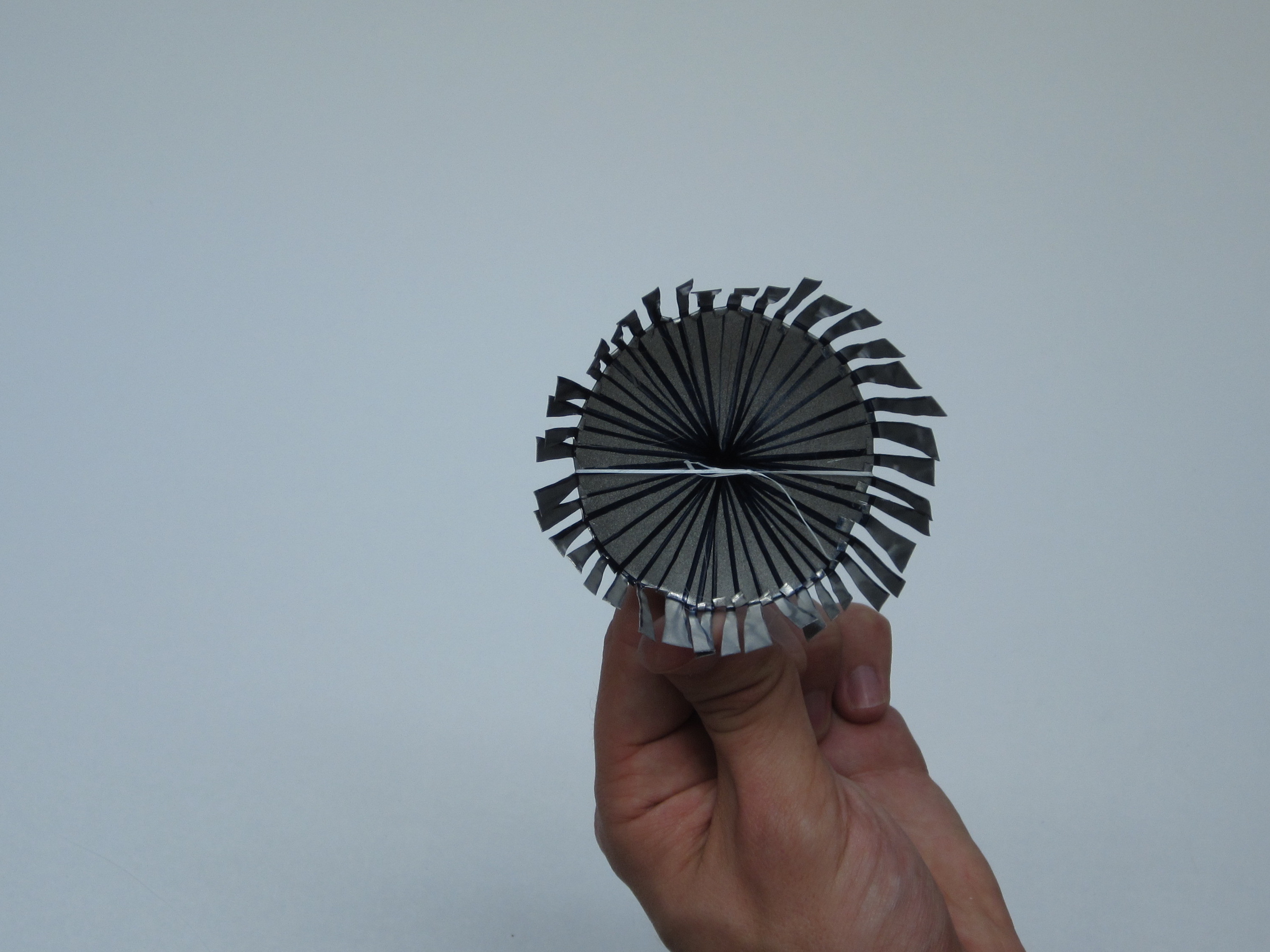

Insert the metal platform into the Pringles can and slide it to the bottom. If some of the cardboard on the inside of the can is sticking out, there is a chance that the platform may get stuck. If this happens, just spin the platform clockwise and it will come loose.

Then all you have to do put the chips back in the can and you are done. The easiest way that I have found to get Pringles back in the can without breaking them is to make an upside down stack of chips, slide the can over the top and then carefully flip them back upright.

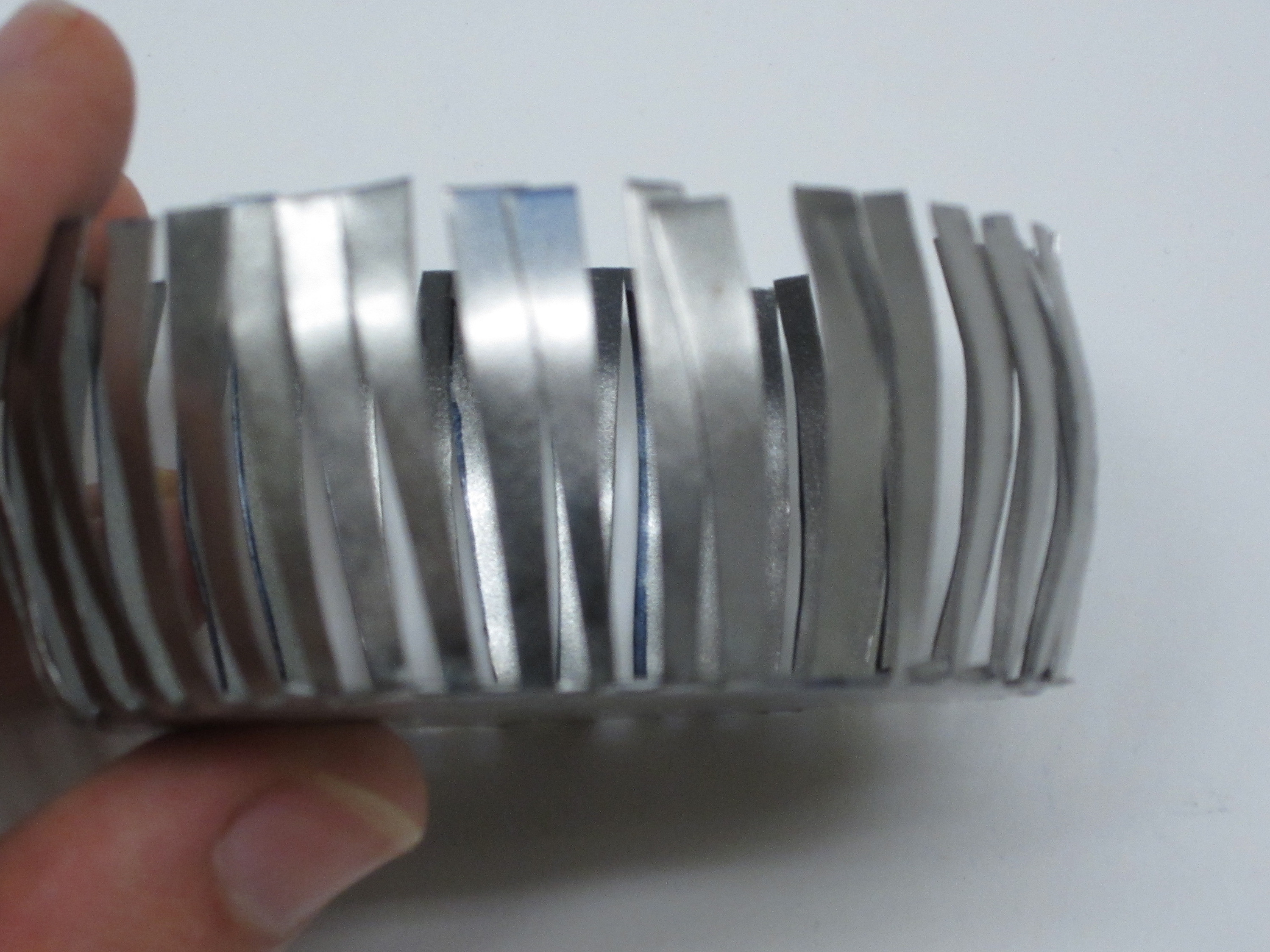

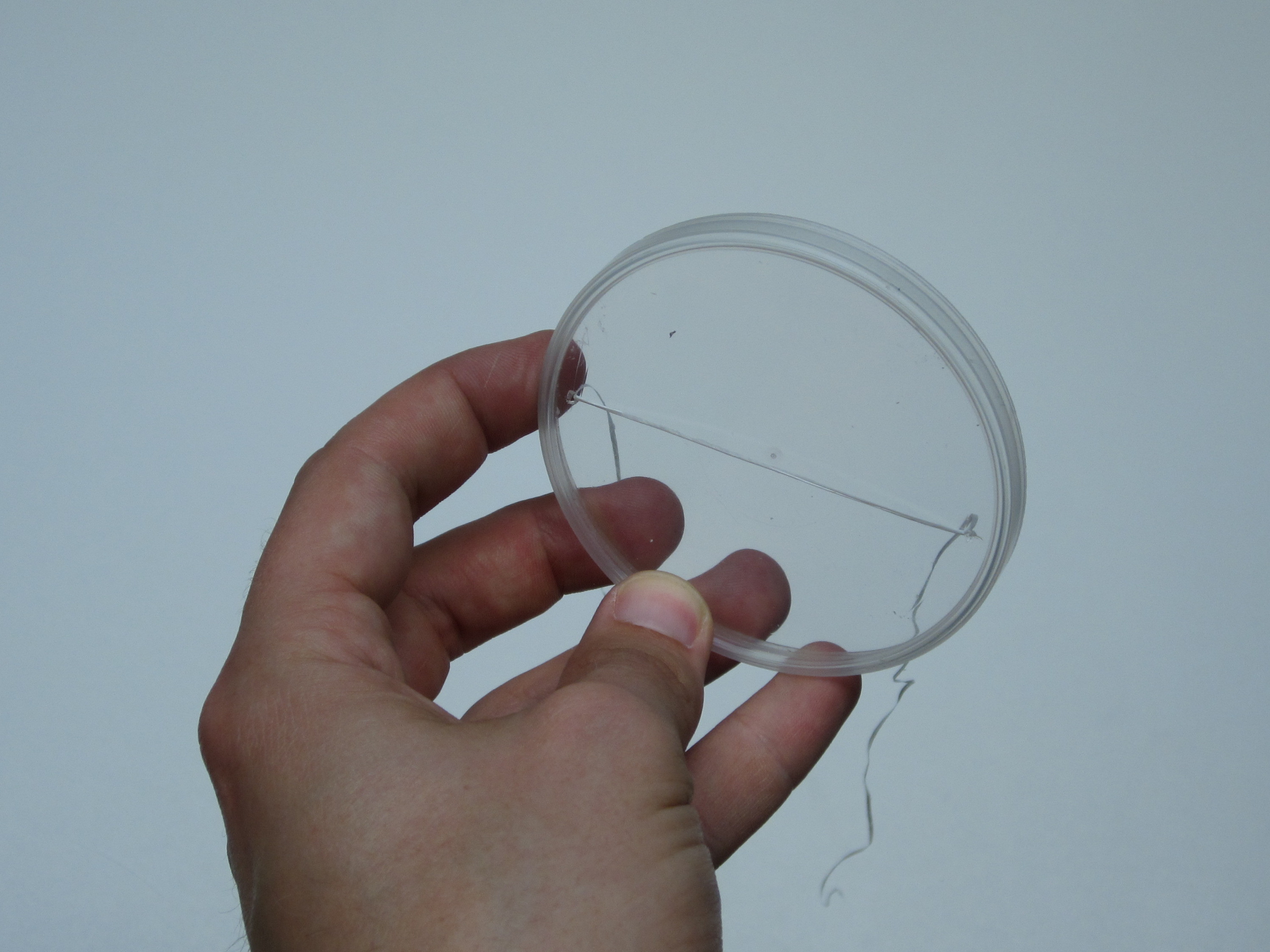

Then whenever you want to raise the level of the chips, just pull up on the lid. The strings will pull up on the platform raising the chips, and friction should hold it in place.