Nope, you can’t get one there, you gotta make it yourself.

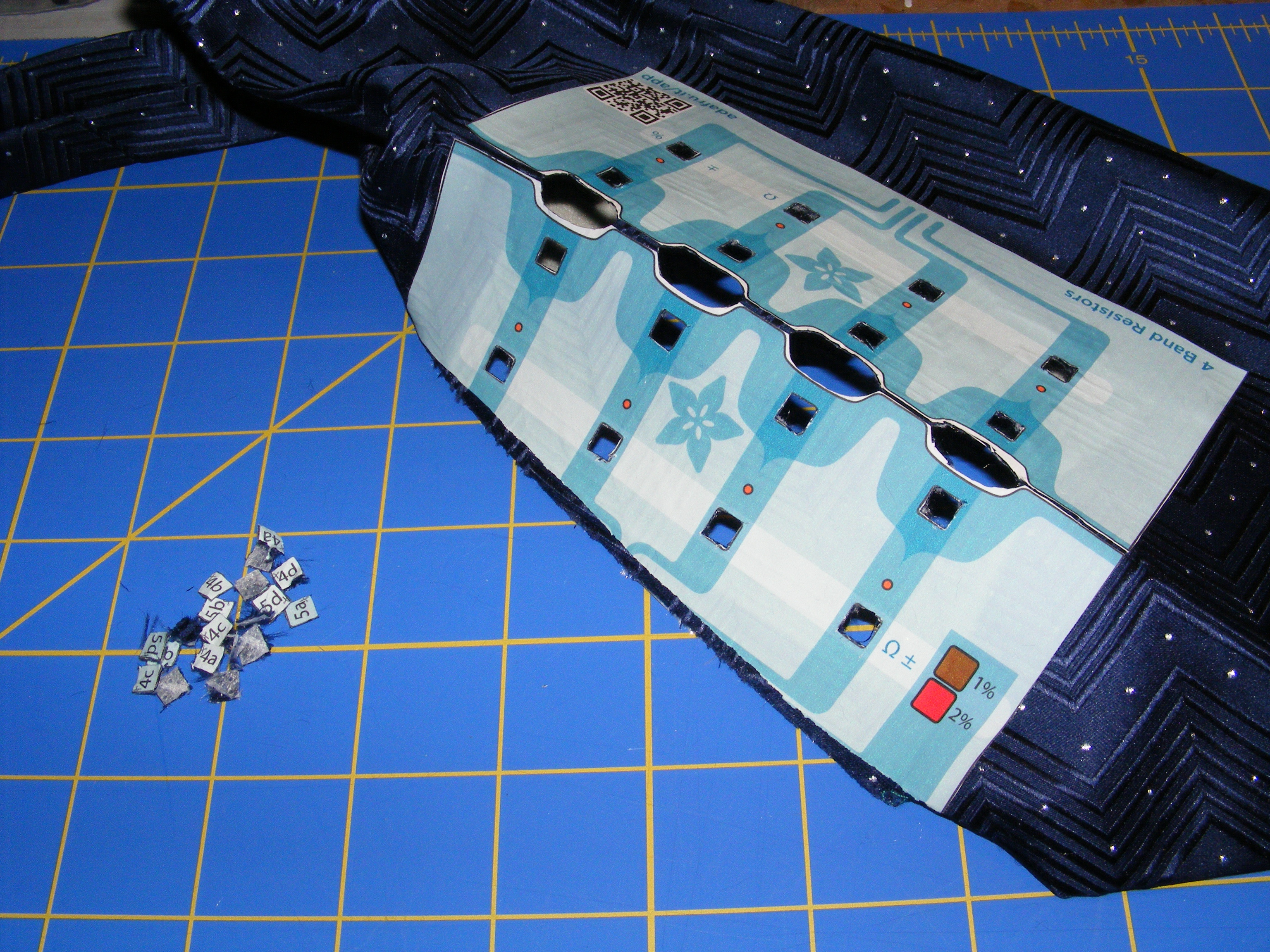

Unless you are one of those who can remember the entire color code for 4- and 5-band marked resistors (test later on how many possible combinations there are; I’m still working on wiring up CAT-5 correctly), you need the help of a reference chart or you can use the handy papercraft Adafruit Resistor Helper. Seeing that it is Father’s Day soon, what better time to give the gift of a tie? Of course, for the geek and technically inclined, a hacked tie would be even better.

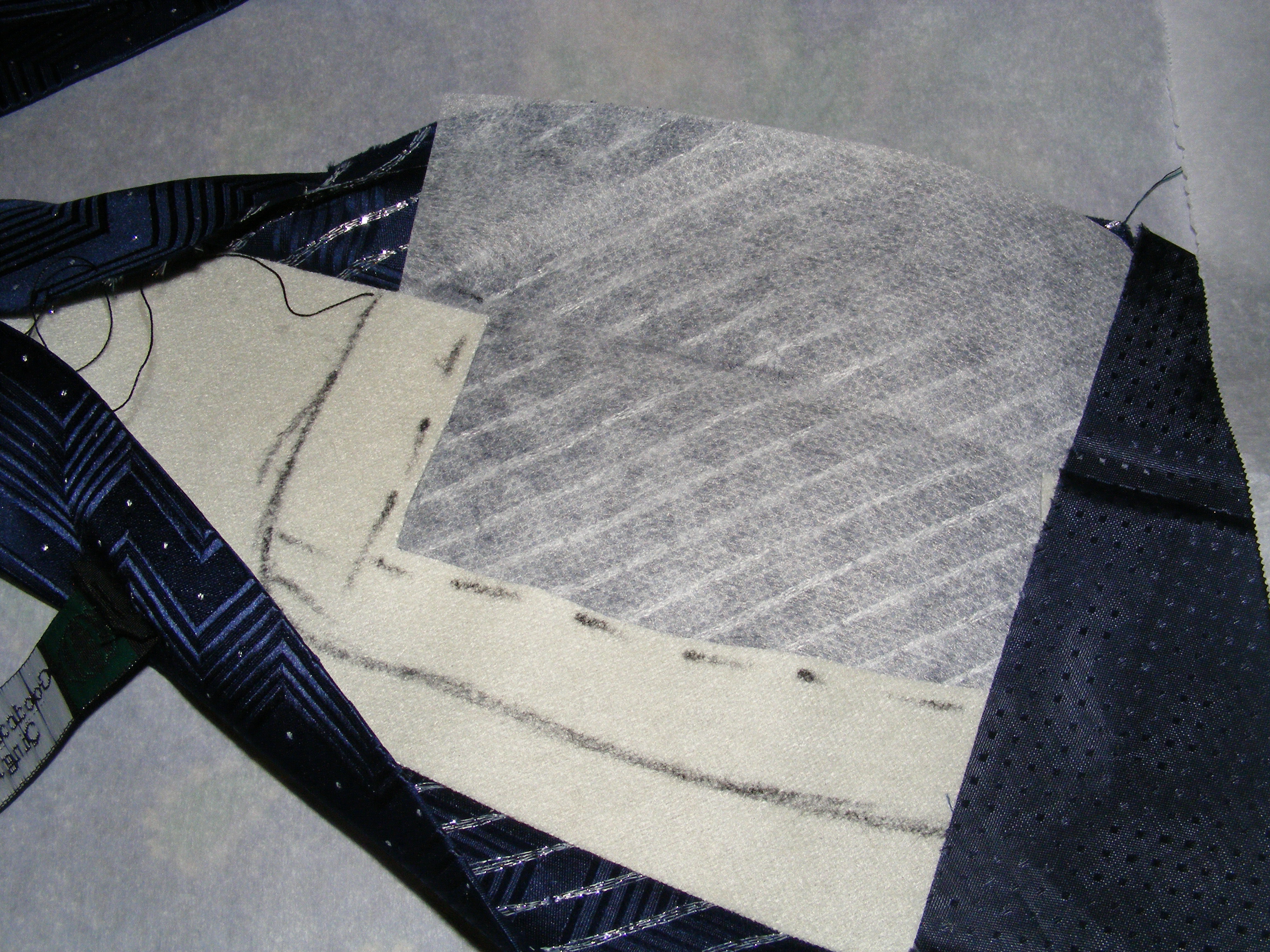

You can make a resistor tie from scratch but you can also repurpose old ties too. Do something with those old power ties to make them current.

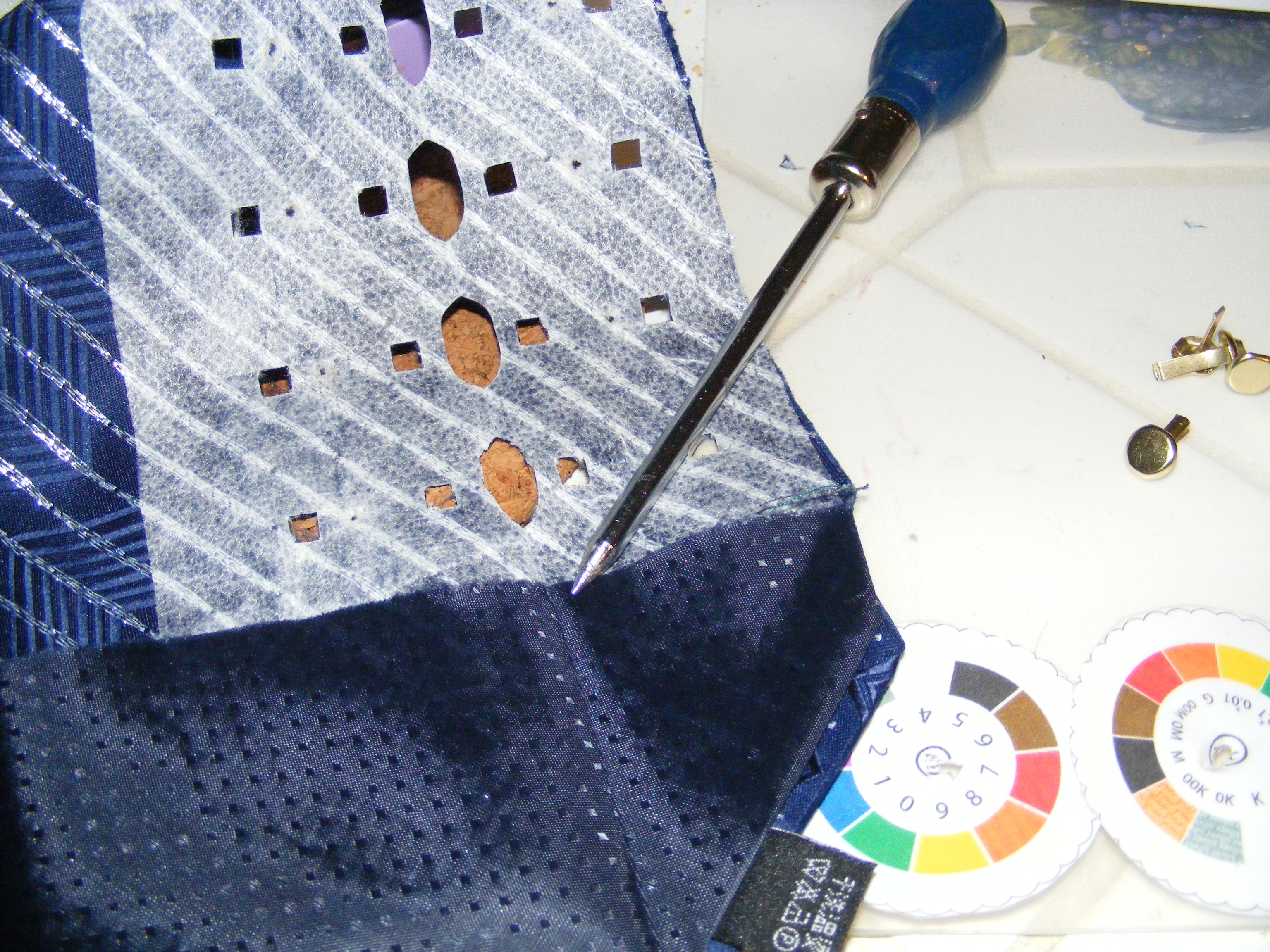

I am just going to use a tie I found at the dollar store (really $2, it had a cool sparkly techno vibe in the pattern) and make a few quick mods to implant the papercraft resistor helper.