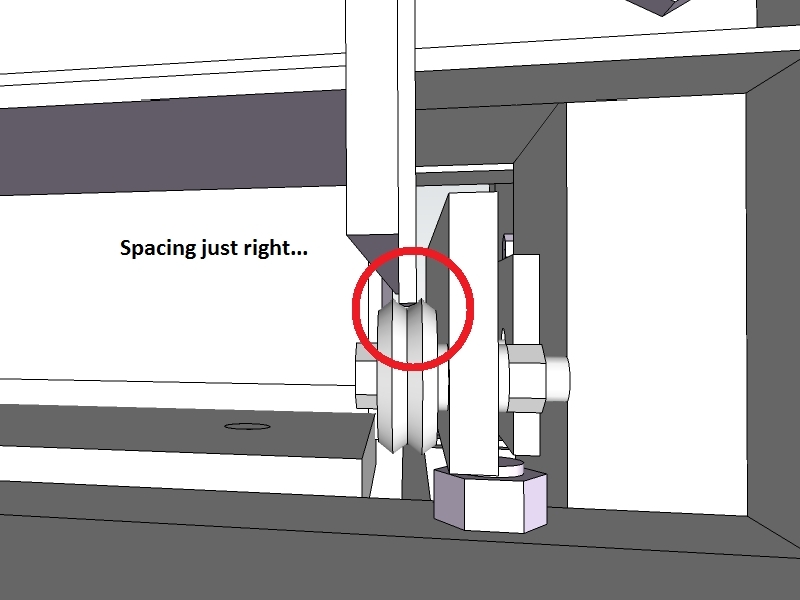

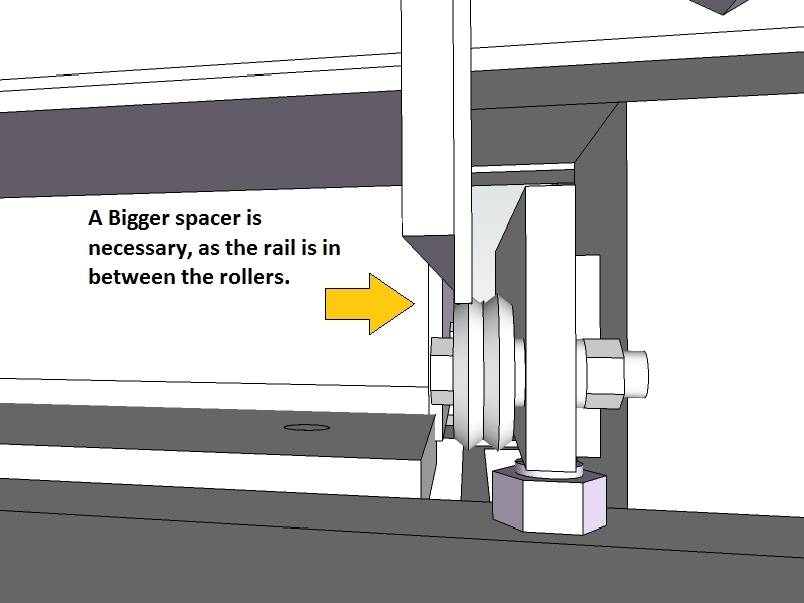

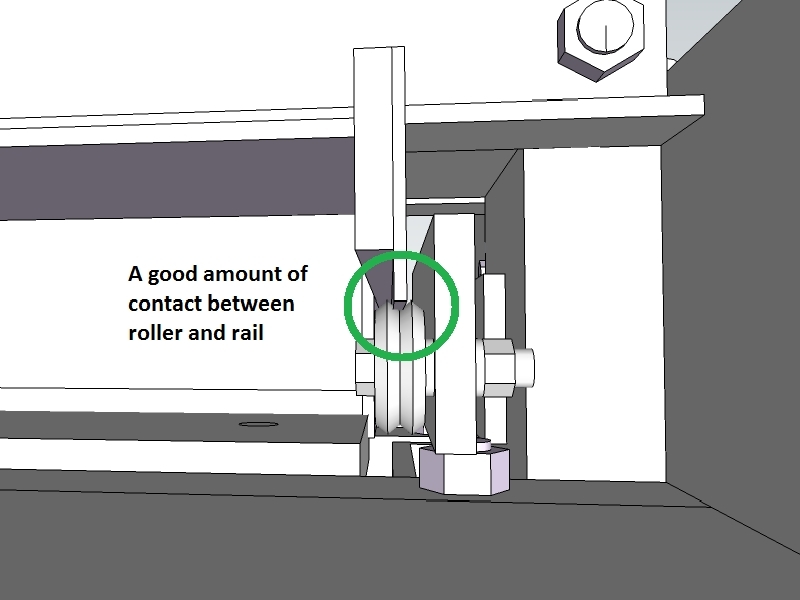

If for some reason the rails and the rollers aren’t spaced properly (the guides need to be closer or further apart) remove one of the guides and switch out the spacer on it to one that will space them properly.

If only one roller of the four is off, the guide is not parallel with the drawer.

Try tightening the nut that attaches the rollers to the frame.

If that doesn’t work, you might have welding spatter or something between the guide and the frame. Remove it and check.

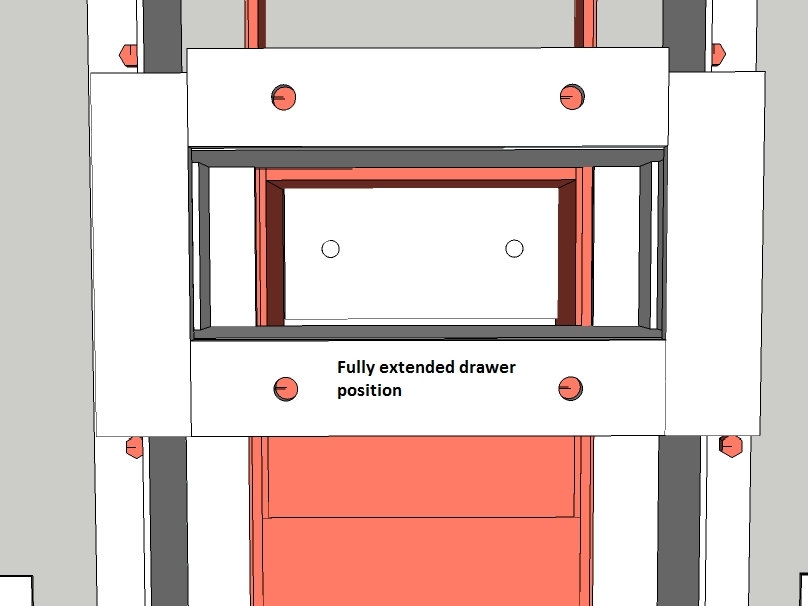

If none of the above steps make all the rollers align, your drawer is likely flawed.

The rails are probably not parallel. Take the drawer out and double check by measuring the separation of the rails.

If they aren’t parallel, see http://opensourceecology.org/wiki/CEB_Pr…