“Astronaut ice cream” is one of those museum gift shop novelties that sticks in one’s childhood memory, just as the ice cream itself sticks to one’s teeth. This treat has an unusually brittle, crunchy quality, but quickly melts in the mouth into a sweet, sticky variation of the real thing. Despite its name, astronaut ice cream was never eaten by astronauts in the form currently sold in gift shops. The brittle, crumbly nature of the food would be hazardous in zero-gravity because the loose crumbs could be inhaled as they floated around the spacecraft. Apollo 7 astronauts did have a ground-up, compacted version of freeze-dried ice cream, gelatin-coated to contain the crumbs, but many subsequent missions have instead included traditional, frozen ice cream for the crew.

The novelty ice cream is created by freeze-drying, a process in which ice cream is dried in a controlled environment. At the proper conditions of low temperature and low pressure, the ice crystals in the dessert convert directly to vapor without melting into water. Thus, the physical structure of the ice cream is preserved because the ice crystals turn directly into gas, leaving tiny voids in their place instead of melting into a thick liquid which would allow collapse of the overall shape and an increase of the density. The same process occurs slowly to uncovered food that’s left in a frost-free freezer, and is known as freezer-burn.

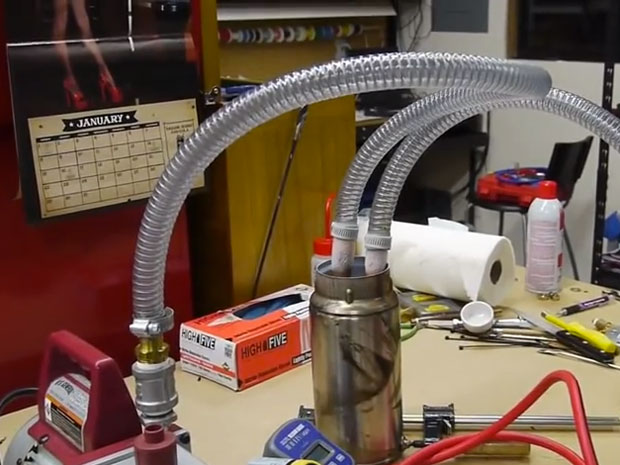

I’ve wanted to make my own astronaut ice cream for quite some time, and one day realized that I had amassed all of the required parts by building and dismantling other unusual contraptions in my shop. The key pieces of equipment I needed to freeze-dry the ice cream were: a vacuum pump, large-diameter vacuum tubing, a cold-trap made from copper pipe and an insulated flask, a glass jar to hold the ice cream, and a tungsten light bulb. Here’s my basic procedure, which I developed by reading online sources of information and by trial-and-error.