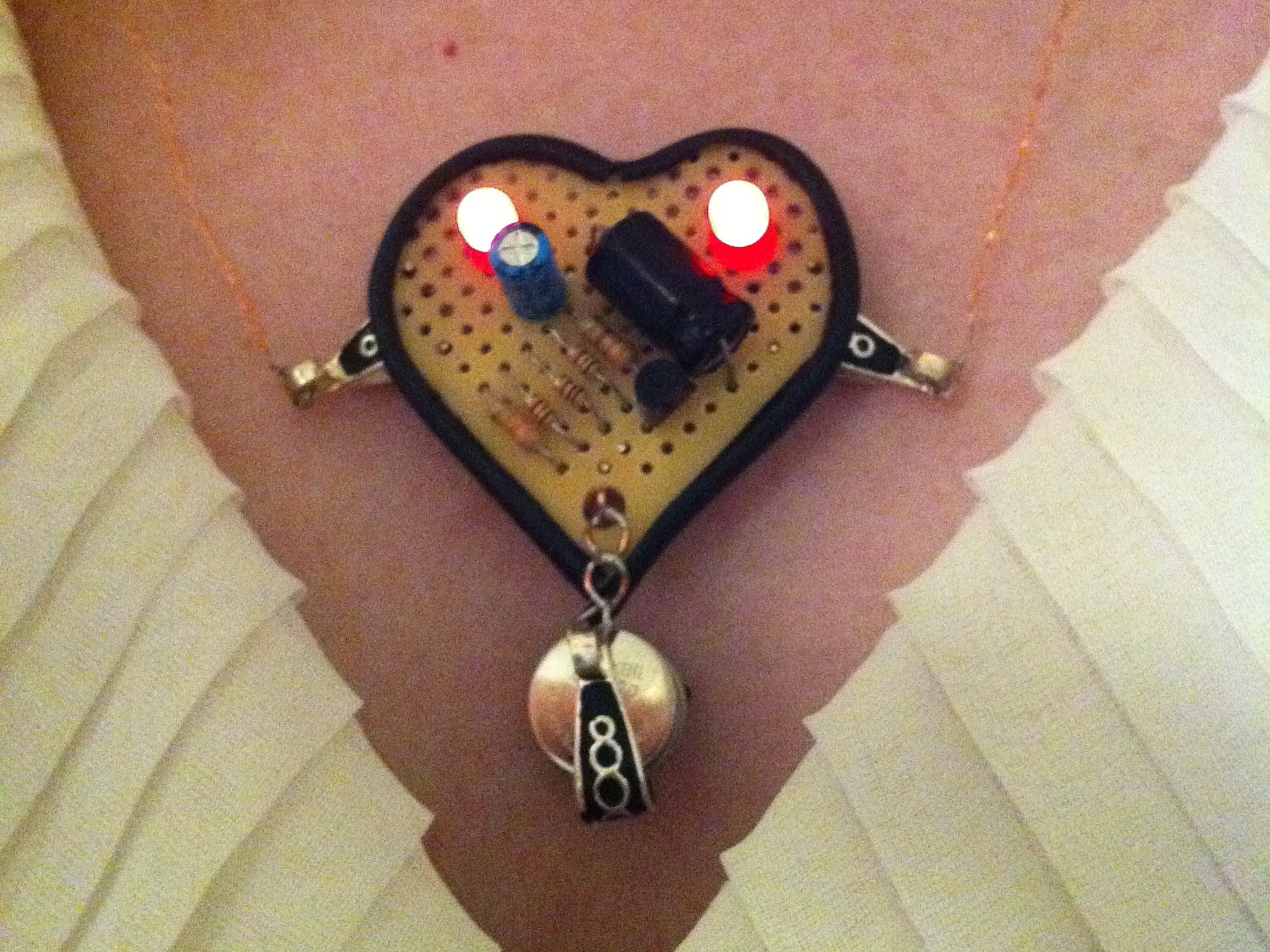

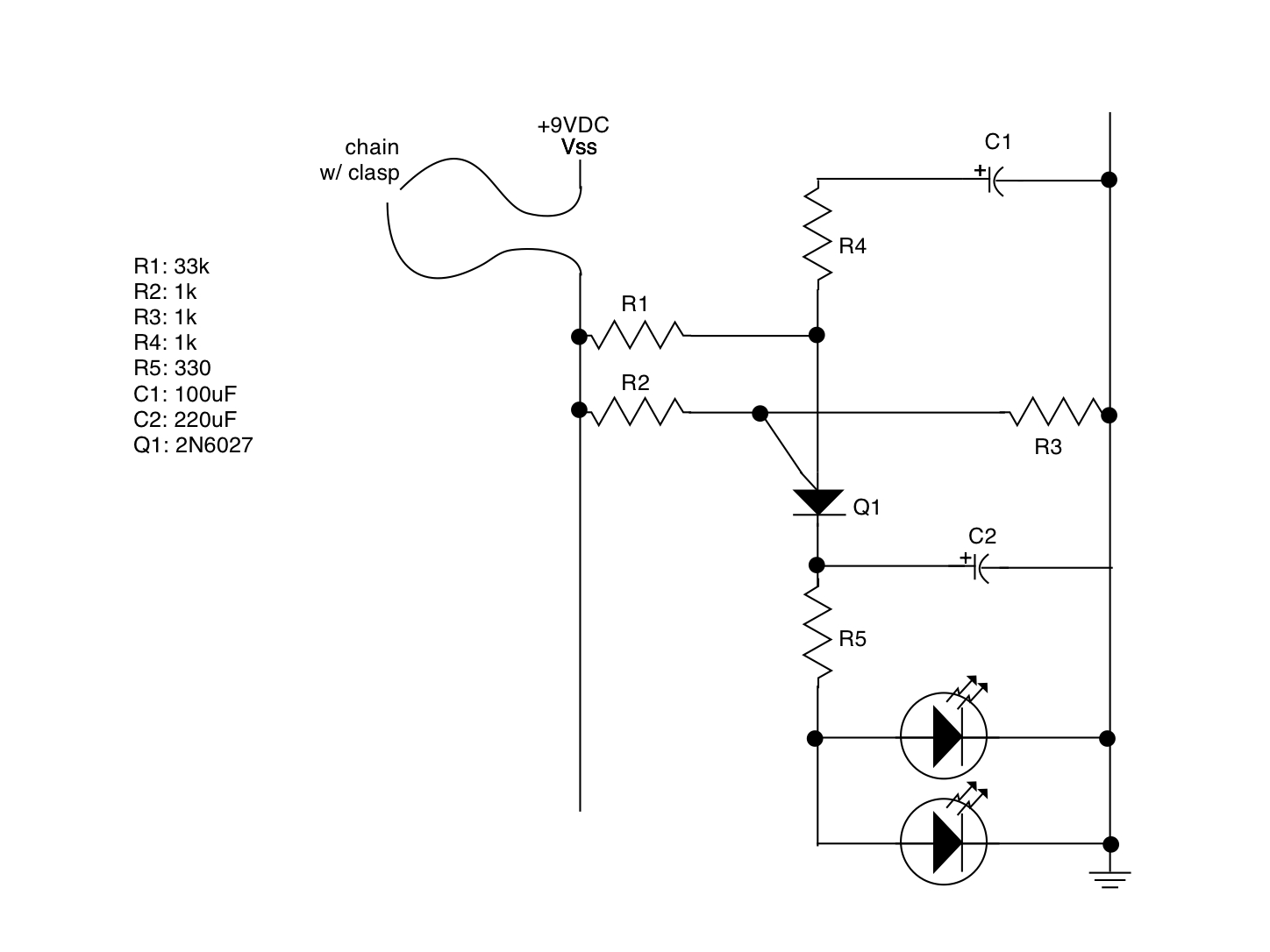

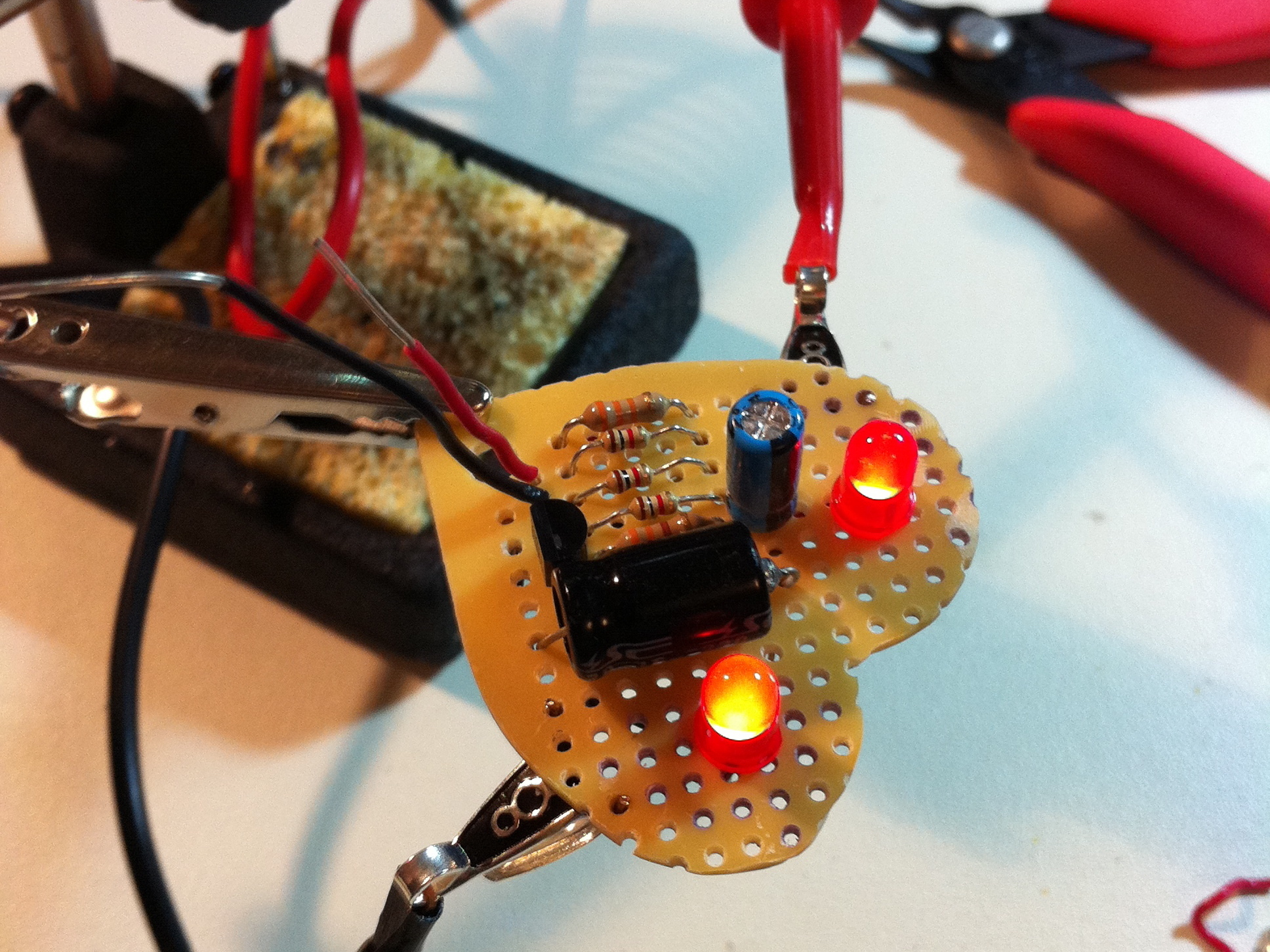

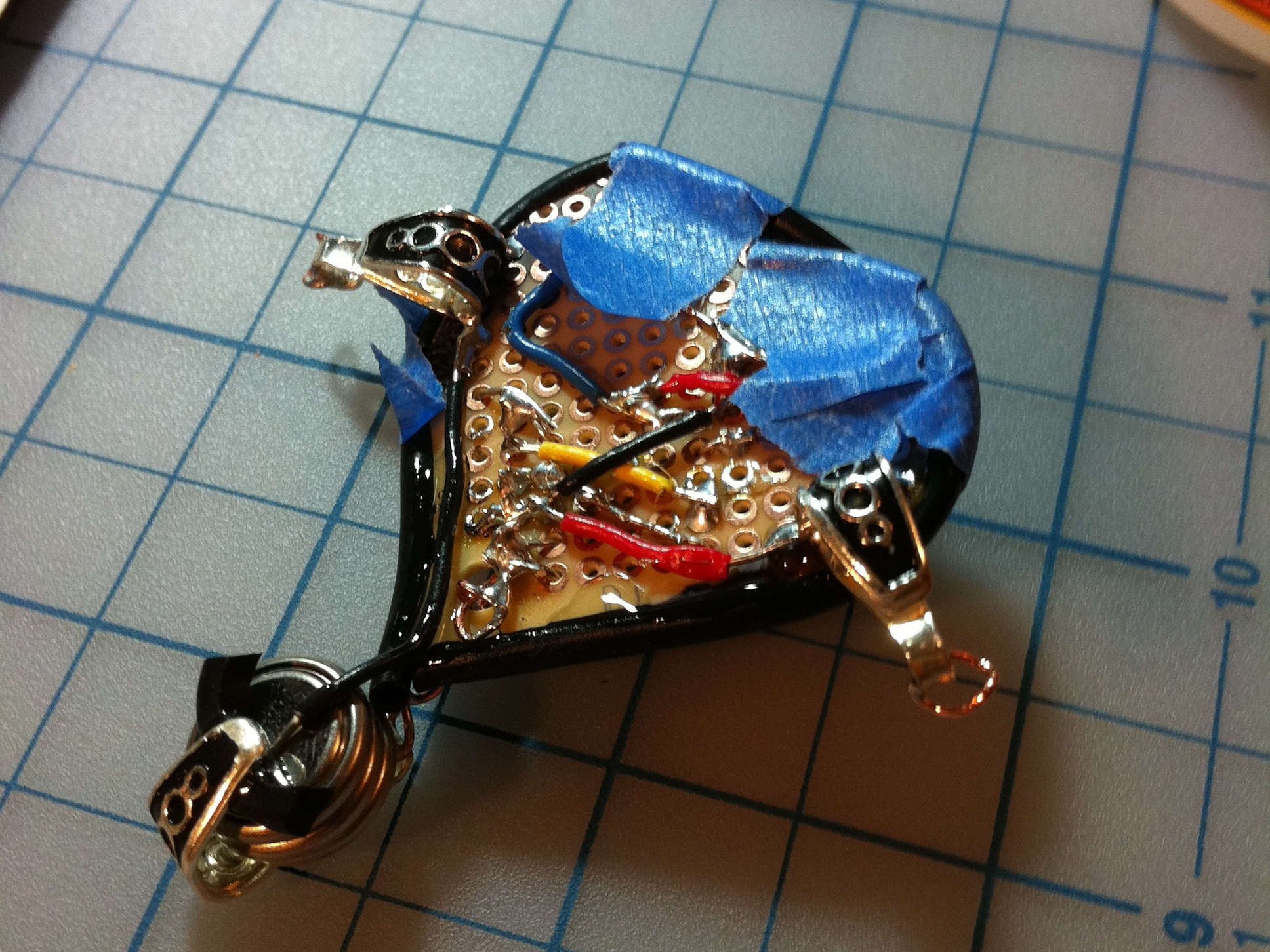

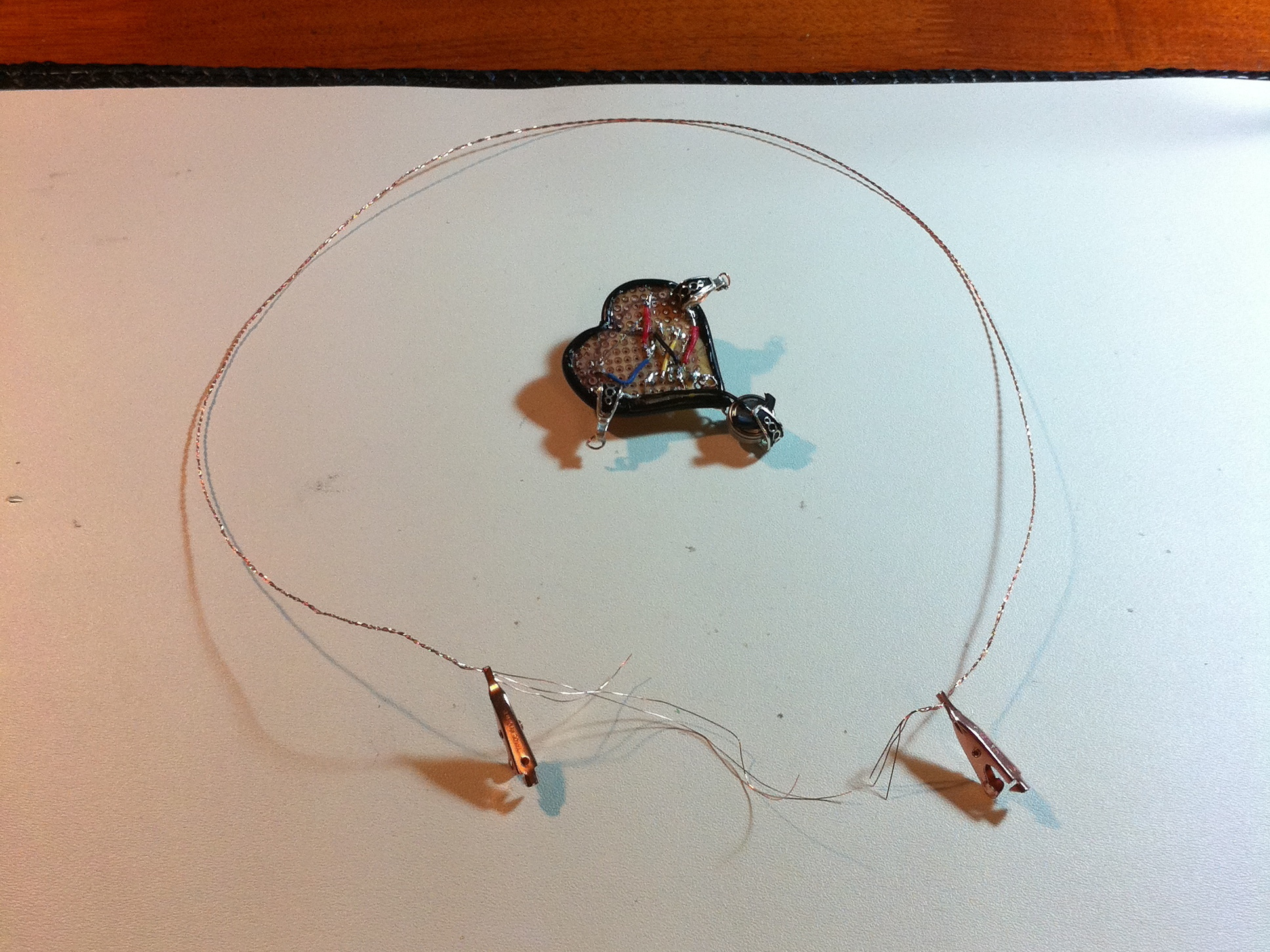

While reading through Charles Platt’s excellent book Make: Electronics, I came across this nice little circuit for making a gentle pulsing LED. I was struck by the “humanness” of the pulse, but couldn’t figure out what to do with it. Later I found a heart-shaped tag on some pants I had bought, and well, this is the result. I opted to use mainly scrap parts salvaged from old computers. I liked the hacky, recycled feel that gave it.

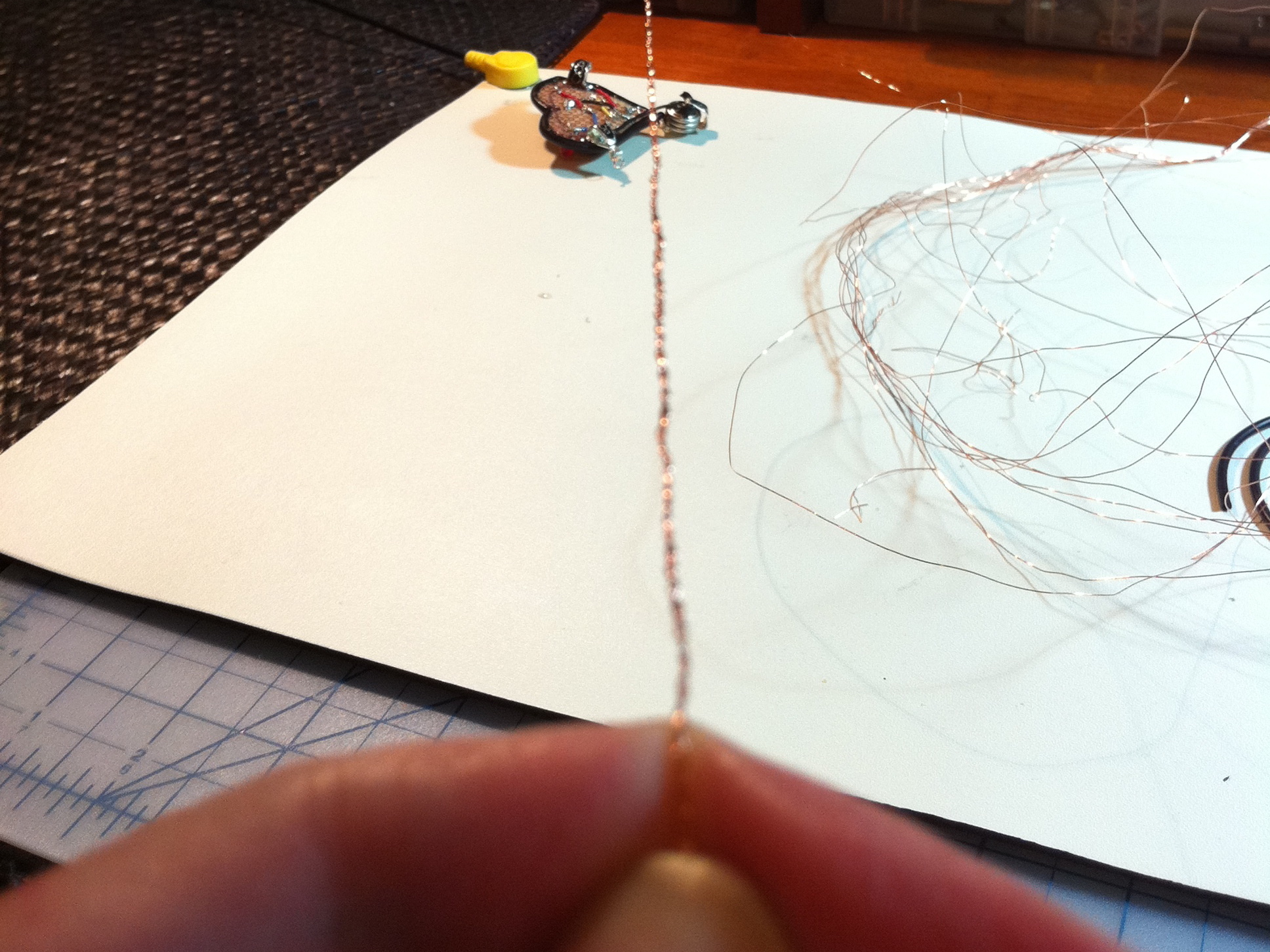

I took Charles’ circuit, and added a second LED for some symmetry. A bob under the pendant provides the power. The pendant’s chain is part of the circuit, so the clasp becomes the on-off switch.