The kit can be purchased here: https://www.trossenrobotics.com/p/Turtle…

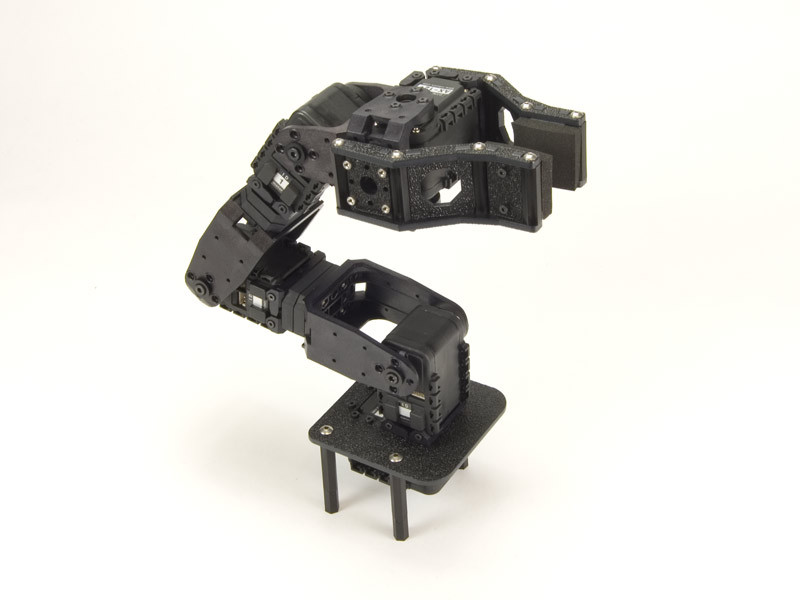

It is a ready-to-build kit based upon the original TurtleBot Robot Arm found here: Build an Arm for Your TurtleBot

This build guide assumes that you know how AX-12 brackets are mounted to AX-12 servos. You must seat M2 nuts into the rows of sockets prior to bolting them down. Please refer to this video for instruction:

http://www.youtube.com/watch?v=o0JtXuj7H…

We also recommend the use of Loc-tite or a similar threadlocker:

http://www.youtube.com/watch?v=ISpqtMfSG…

Please note that the AX-12A servos that come with this kit have pre-assigned IDs.