The Tiny Wanderer robot is meant to be played with. After you have explored the two IR sensors that come with the kit, it is time to try new robot behaviors and sensors. To let your robot wanderer around your house, it needs to be able to detect and react to obstacles in its path. While this can be done with the IR sensors, that method makes heavy use of the limited input/output pins of the Tiny Wanderer’s ATTiny85 robot controller. We can free up two of the pins by instead adding a bump sensor in place of the two IR sensors.

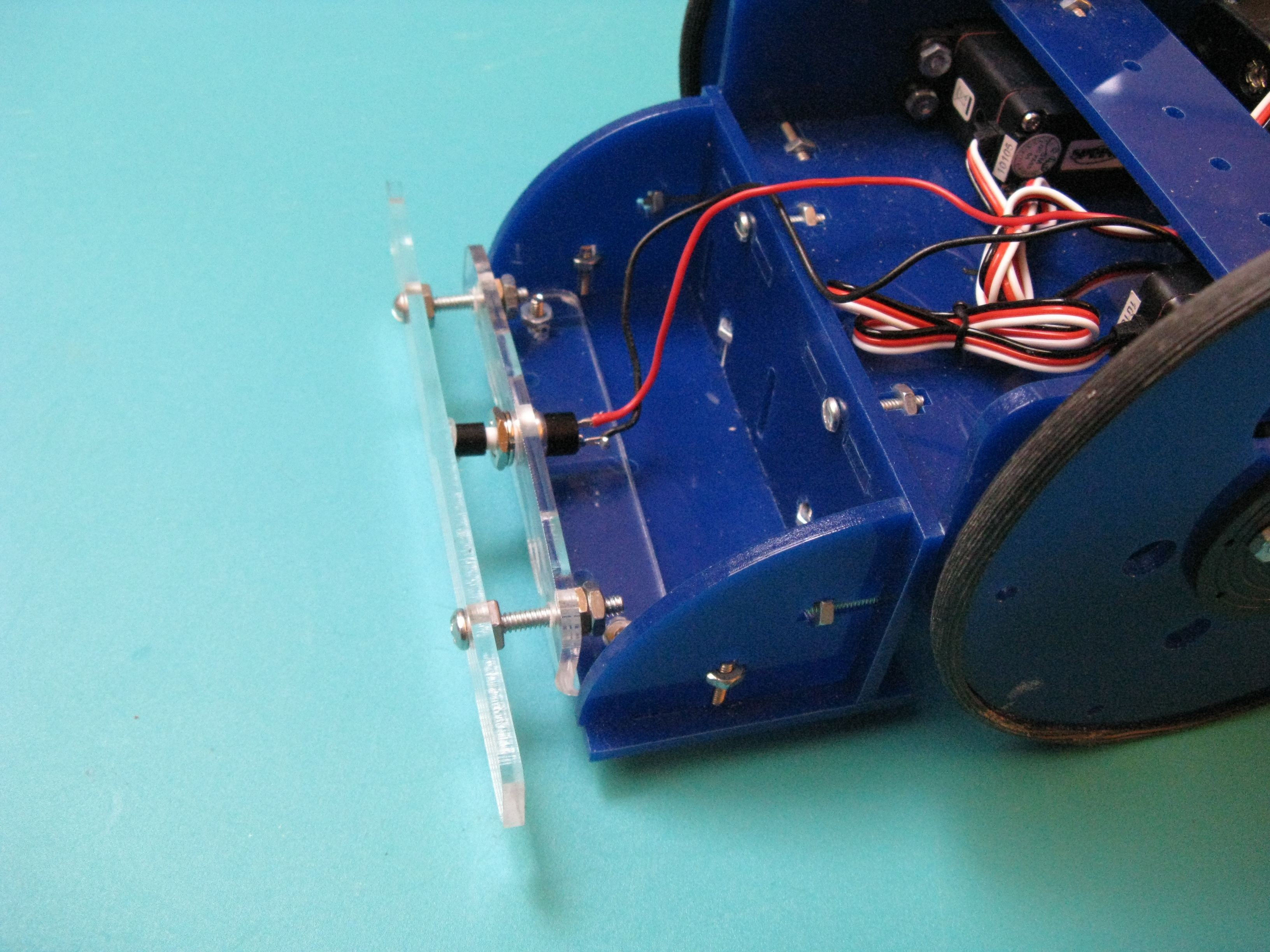

Here is how you can make a bump sensor for your Tiny Wanderer inexpensively using easily obtained materials.