Additional Materials Required:

- 1″ Keyed Coupler

- 1/4″x 2″ Bolt

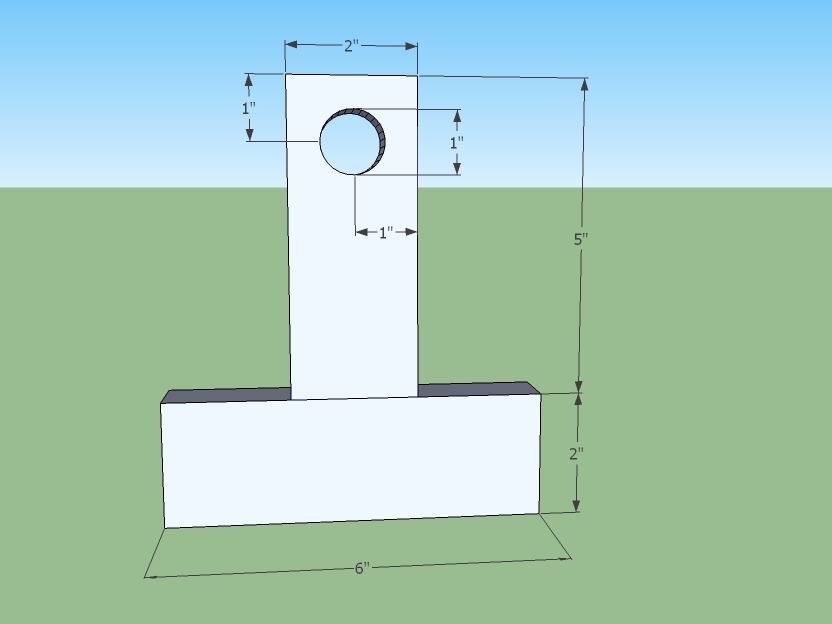

Drill or punch the hole in the flatbar.

Weld the two pieces of flatbar together

This needs to be a really strong weld! The hammer will be under a lot of stress, and if it’s not a solid weld, it could fly off! (This is why the guard is there).

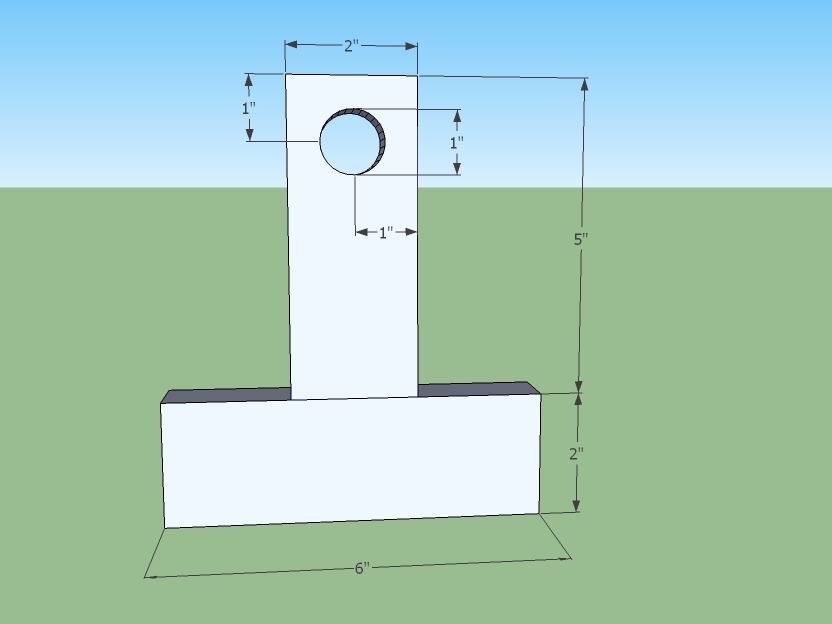

Tack the shaft into the hole so there’s about a 1/4″ distance between the end of the shaft and the opposite side of the hammer.

Cut the coupler down so it’s 2″ long. It doesn’t matter from which side you cut it.

Get the shaker motor, the mount you made, the shaft/hammer, and the coupler.

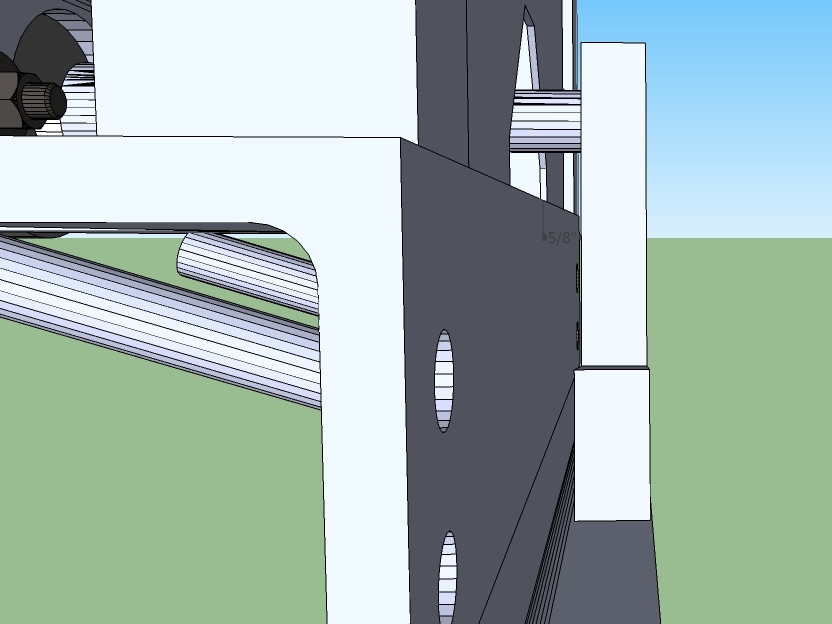

Put the shaker motor onto the mount and couple the shaft to it. Mark where the shaft enters the coupler.

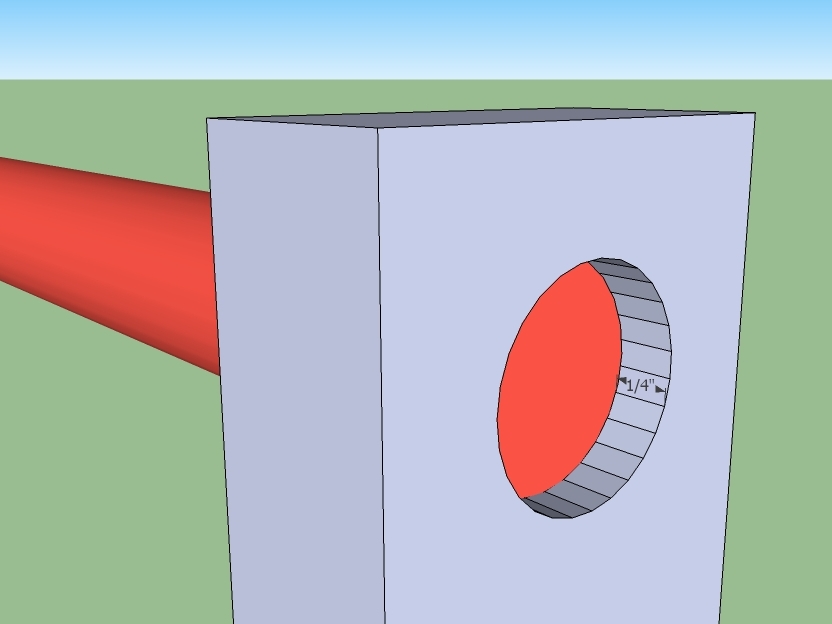

Make sure the coupler won’t be rubbing on mount while it spins.

Make sure the hammer has about 5/8″ clearance from the mount.

If not, you can pull it out of the coupler a little, but make sure the bolt won’t be too close to the edge.

Otherwise, you can grind away the tacks on the hammer and tack it properly.

Remove the motor and shaft from the mount

Put the coupler back onto the shaft.

Drill the 1/4″ hole thru the coupler and rod, using the mark you made to make sure the rod is inside the coupler the proper amount.

The hole should be 3/8″ away from the edge of the coupler.

Drill thru both at the same time. You will need some sort of vice to hold it down while you drill.

Double check that your bolt will fit thru. If not, either re-drill it with a slightly bigger bit, or do another set of holes.

Remove the coupler

Fully weld the hammer to the shaft, plug-welding the back side, and welding around the shaft on the other side.

Make sure this weld is SOLID.