So why would you want to make your own roller skates? Because you can! Imagine rolling into a rink and turning heads as skaters check out your original, cool-looking skates. Not only will your custom skates set you apart in terms of style, fit, and comfort, they’re also a great conversation piece with the irresistible appeal of being able to say you made them and they’re not found in stores. The coolness factor is priceless!

A well-made pair of custom roller skates can last you years, with countless hours of fun to be had. Studies have shown that 1 hour of moderate roller-skating by a 140-pound person burns 330 calories, and vigorous skating up to 590 calories. Apart from the health benefits, skating is also a great way to socialize with other skaters at the rink or park.

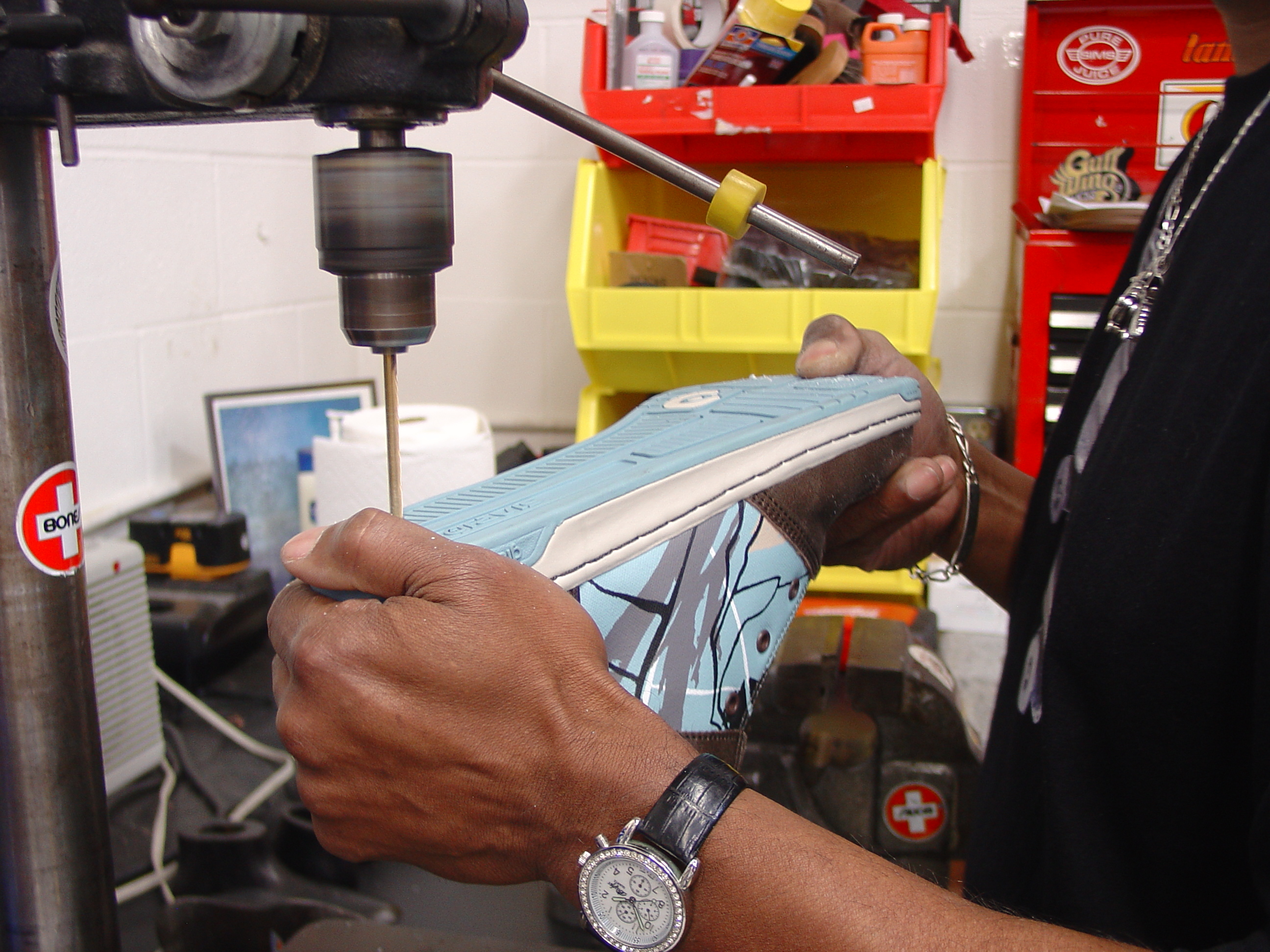

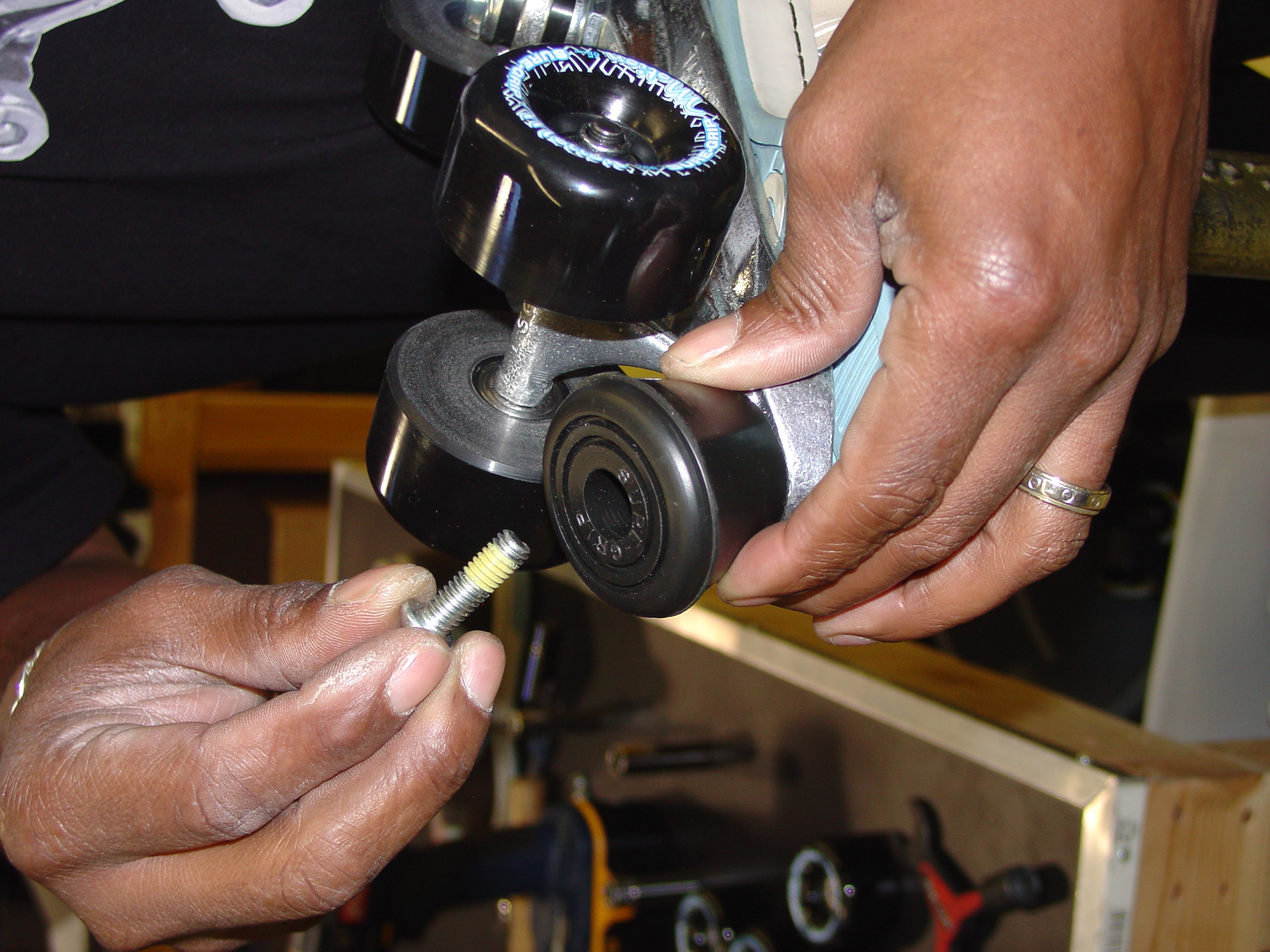

This step-by-step instruction guide should be followed carefully to ensure the safety of your skates. And of course, always remember to wear protective gear when skating!

Check out a video of the build!