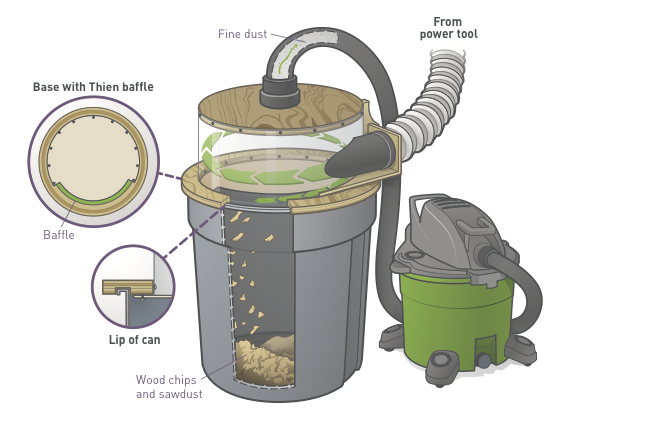

Here’s a rewarding weekend project that turns an ordinary shop vacuum into a capable mini dust collector. It creates a swirling vortex of airflow to spin out all the big chips and sawdust particles, so that only the finest of fines will exit the top to be captured by your vacuum. Plus it’s see-through, so your friends will love watching the cyclonic action, and you’ll get to brag, “Yeah, I made that!”

This is an easy-to-build dust separator with a baffle based on J. Phil Thien’s well-known “cyclone” design. It works because the incoming air is forced around the outside wall, where the heavier dust and chips fall through a slot in the baffle, into the large trash can below. When driven with a blower like I use, the baffle removes the need for a standalone dust collection system (which not everyone has the money, space, or power to accommodate). When used with a shop-vac, this simple dust collector will greatly prolong the life of your filters and prevent the constant need to empty the vacuum bin, which is typically small and difficult to remove.

IMPORTANT: The measurements presented here are tailored to fit the trash can I used. If you’re using a different collection vessel, you’ll need to alter all of your measurements to fit.

DIY Dust Collection

Whether it’s sawdust, carbide grit, aluminum shavings, or powdered circuit boards, you don’t want that stuff clogging your workpiece, your eyes, or your lungs. A dust collection system not only protects your health, it also keeps your tools cleaner and safer, reduces fire risk, and keeps mess off the floor.

Systems for big workshops typically have a powerful central vacuum and dedicated 6″ or 4″ hoses for each tool, with “blast gates” to shut off the suction to tools not in use. That’s a doable DIY project if you’ve got lots of space. But most small workshops can benefit greatly from a movable system based on an ordinary wet/dry shop vacuum and its standard 2½” hose — like the cyclone separator described here.

Dust Collection Tips

- Newer bench/table tools may have a standard 2½” dust port, where you can plug in a shop-vac hose. Hand tools like sanders are easier to operate with a 1¼” hose.

- To mate different ports and hoses, you can buy standard adapters at your local home store or cut down a universal adapter to fit — but you should still plan on needing duct tape, because many toolmakers haven’t yet standardized their dust fittings.

- Ditch the dustpan — instead, push debris into a dedicated “floor sweep” box attached to your vacuum.

- Swap your shop vac’s filter for a HEPA filter to capture the finest dust. But wear a mask or respirator anyway — a shop vac has good static pressure but doesn’t move enough air volume to filter all the air in your workspace.

—Keith Hammond